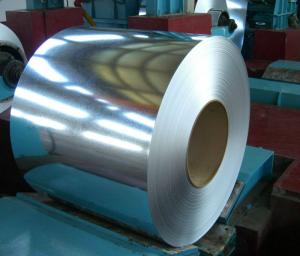

Galvanized Hot DIP Galvanized Steel Rolled Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Info.

Model NO.:wit-gic01

Surface Treatment:Galvanized

Certification:ISO, SGS, BV, RoHS, IBR

Technique:Cold Rolled

Standard:ASTM, JIS, GB, AISI, DIN, BS

Steel Grade:SGCC

Zinc Coating:60-120g

Spangle:Minimum Spangle,Regular Spangle

Size:Customized Thickness Width Length

Export Markets:Global

Galvanized steel coil

Size:0.133x1000mm and others .Please check the following form.

Steel grade:SGCC,DX51D+Z and so on.

Certificate:ISO 9001

| COMMODITY | Galvanized steel plate/coil |

| STEEL GRADE | SGCC,SGCD,ASTM A 653 etc. |

| Standard | GB,JIS,DIN,AISI,ASTM |

| Thickness | 0.13mm ~ 3.0mm |

| Width | 700mm 1000mm 1219mm 1250mm |

| length | below 12000mm or coil |

| Coil ID | 508/610mm |

| Coil Weight | 3-12tons |

| Surface | Zinc coating 60-250g/sqm |

FAQ:

Acceptable payment term and way?

T/T,L/C, T/T + L/C, D/P

Acceptable price term

FOB CNF CIF DDU CPT

Do you accept OA payment terms?

Yes, sure, but it normally depending on the order value

Do you have QC team?

Yeah, sure, our QC team is very important, they will keep the qualitycontrol for our products.

What is the validity of your quotation?

Normally 7 days.

What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

What is your acceptable payment term?

TT,LC,OA etc

- Q: I bought this Brinks pad lock and it says boron steel on the lock. I was just wondering what exactly is boron steel and how hard/tough is it?

- Boron steel is rather hard, it is by no means titanium, but certainly better than mild steel. However, as with all metals, hardness is inversely proportional to flexibility, meaning that a good solid whack with a sledge hammer could crack your lock.

- Q: How are steel coils inspected for mechanical properties?

- Steel coils are inspected for mechanical properties through a series of tests and measurements. These include hardness testing, tensile testing, and elongation testing to determine the steel's strength, ductility, and overall quality. Additionally, non-destructive testing methods like ultrasonic testing and magnetic particle inspection are used to detect any potential defects or flaws in the coils. Overall, a combination of these inspection techniques ensures that steel coils meet the required mechanical properties for their intended applications.

- Q: For some reason, if you rub iron oxide or lodestone (both very crumbly, dark, mineral-like materials) into soft, unhardened steel, their particles actually get stuck into the surface of the steel (that is, darkening it). My question is, how does this work? How come iron oxide and lodestone can get stuck, and how come other materials (like silicone carbide, for example) do not?My second question is, are there any materials that can get stuck into steel, that is also blue in color, and how would I best obtain it?

- If you look at the surface of untreated steel even with a low power microscope you will see a surface that is far from smooth, there are pits and occlusions dotting the surface. Steel is not polished when you see it this way so the only treatment to the surface was the extrusion process or forming done on it by the presses. Iron oxide has a very small particle size and when pulverized into a powder it can easily fill the pits and voids in the steel surface coloring it.

- Q: All of my friends say that if a car made of mostly carbon fiber would crash into a full steel car, or vice versa, the steel car would be DESTROYED and the carbon fiber would drive away, if not, easily repairable.

- Ok, your friend is wrong. Carbon fiber can outperform steel in many applications. It is lighter and stronger in tension. Compression, however, is not a property carbon fiber composites do well under. The strength of carbon fiber composites comes from the design, or layup, of the fibers. When the layers are properly orientated the composite can do very well. But, it can’t handle stress from any direction, only the directions it’s designed to be used in. Now, back to the car crash… A crash is a situation involving high amounts of crushing forces and shockwaves that would travel around the vehicle. If the impact itself didn’t crush the composite, the shock waves could cause hidden damage, such as delimitation, in areas that may not even be close to the impact area. As for it being easy to fix, well that is also dead wrong. Unlike steel, carbon fiber composites can’t be welded, straightened, or bent into place. Once a composite has sustained damage it usually needs to be replaced. Closing thoughts… Keep this in mind, it’s not the fibers themselves that are so weak, it’s the glue holding them together. As of today, the only way to make these strong light weight components is to glue them together. They do a good job doing what they are designed to do, but fail easily with impact and compression loading.

- Q: I have a carbon steel file that I want to bend in a letter C shape. So, what is the malliable temperature? If it's low, could it be done in a camp fire?

- It needs to be RED hot, the hotter the better. Yes you can use a camp fire if you put the file directly in the hottest part of the coals, but it'll take about 5-10 minutes to heat. Charcoal briquettes would probably work better as a heat source. You can use something like a blow dryer to intensify the coals, that might help. You'll also need a bench vice, and the biggest pair of pliers you can find, for leverage. Bending steel's not easy even when it's hot. You could also use a bit of steel pipe that'll fit over the end of the file. Stick the file in the vise when red-hot, slip the pipe over the free end, and use the pipe to bend it. OR, you could use the old-fashioned method of just holding it with pliers in one hand, and hitting it with a 5lb sledge hammer with the other. use something solid as an anvil, like a large steel pipe. you mighe be able to get away with using a small log, but you'll have to work twice as hard. Safety glasses are MANDITORY for this type of thing. Do not attempt without eye protection at all times. Ear plugs are also a very good idea.

- Q: What are the different coil coatings available for steel coils?

- There are several different coil coatings available for steel coils, each offering unique benefits and characteristics. Here are some of the most common coil coatings used in the industry: 1. Polyester: Polyester coil coatings are widely used due to their excellent durability and resistance to fade, scratch, and corrosion. They provide good UV resistance and are available in a wide range of colors. 2. Polyvinylidene fluoride (PVDF): PVDF coatings are known for their exceptional resistance to weathering and UV radiation. They offer excellent color retention, gloss retention, and overall durability, making them suitable for outdoor applications. 3. Polyurethane: Polyurethane coil coatings provide a high level of abrasion resistance and flexibility. They offer excellent chemical resistance and are often used in industries such as automotive and appliances. 4. Silicone modified polyester (SMP): SMP coatings offer good resistance to fading, chalking, and cracking. They provide excellent weather resistance and are commonly used in architectural applications. 5. Epoxy: Epoxy coil coatings are known for their excellent adhesion and chemical resistance. They are often used in demanding environments such as automotive parts and appliances. 6. Plastisol: Plastisol coatings are PVC-based and provide a thick, flexible film on the surface of the steel coil. They offer excellent corrosion resistance and are commonly used in the construction industry. These are just a few examples of the different coil coatings available for steel coils. The choice of coating depends on factors such as the intended application, environmental conditions, desired appearance, and required performance characteristics. Consulting with a coil coating expert can help determine the most suitable coating for a specific project.

- Q: Can someone help me...i have a diagram and were supposed to calculate the steel tonnage needed for the pictre. Can someone tell me step by step what i need to do (ex:find area of ...)

- Find the volume of steel and then multiply that by the density of the steel.

- Q: How much money do you think I could get per lb if I wanted to trade in scrap steel material?

- Scrap steel is usually traded per ton. Average steel prices fluctuate on a daily basis. General prices for scrap steel are around $100 - $200 per ton. For daily scrap steel prices check the source below

- Q: We bought a new fridge and the magnets don't stick to the front where the stainless steel is.

- The stainless steel which dont exhibit magnetic properties are austenitic grades of steel.

- Q: What are the different types of steel coil surface treatments for durability?

- The durability of the material can be enhanced through various types of steel coil surface treatments. 1. To achieve a protective zinc coating on the surface, the steel coil is immersed in a bath of molten zinc in the process of hot-dip galvanizing. This method not only provides excellent corrosion resistance but also extends the lifespan of the steel coil. 2. For indoor applications or when a thinner coating is desired, electro-galvanizing is preferred. This method involves electrodeposition of a thin layer of zinc onto the surface of the steel coil, offering good corrosion resistance. 3. By applying a dry powder paint to the steel coil's surface and curing it under heat, powder coating creates a durable and attractive finish. This finish is resistant to chipping, scratching, and fading, ensuring a uniform appearance. 4. To protect against corrosion, UV rays, and other environmental factors, organic coatings like acrylics, polyesters, or fluoropolymers are commonly applied to steel coils. These coatings not only enhance durability but also improve the aesthetics of the steel coil. 5. Chromate conversion coating involves applying a thin layer of chromate onto the steel coil's surface. This treatment provides corrosion resistance and improves the adhesion of subsequent paint or powder coating layers. Each of these surface treatments offers unique benefits in terms of corrosion resistance, durability, and appearance. The choice of treatment depends on the specific application requirements and the level of protection needed for the steel coil.

Send your message to us

Galvanized Hot DIP Galvanized Steel Rolled Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords