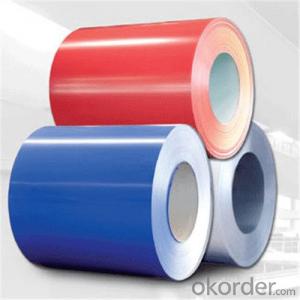

Hot Dipped Galvanized Steel Coil /Pre-painted Galvanized Steel Coil/Pre-painted Steel Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

1. Galvanized steel coil simple introduction:

Galvanized steel coil means that steel coils has gone through a chemical process

To keep it from corroding, so this protective metal, zinc layers, does not get rusty as easily. The coating also gives the steel a more durable, hard to scratch finish.

(1)Thickness:0.14-1.2mm

(2)Width:600-1250mm

(3)Material:SGCC,DX51D,S350GD,SPCC,CGCC

(4)Zn:40-275gsm

(5)Surface:oiled,chromated

(6)Application: Corrugated,Wall,Roofing,Structure and so on

2. Galvanized steel coil technical processing:

1)Uncoiled and sheared

2)Cleaned using a caustic solution, which can remove oil/grease, dirt, and paint

3)Entry looper to revised and then annealing furnace

4)Steel is dipped into the molten zinc bath

5)Cooled in a quench tank to reduce its temperature

6)Post treatment and crimper

3. Galvanized steel coil quality control:

Strict procurement process---skillful technical workers---final products inspection

(resistance to corrosion, salt spray test, exposure test, machinability, thermal resistance)

---standard packing

4. Galvanized steel coil advantages:

1)Zinc coating has good adhesion

2)Resistant to corrosive factors

3)High strength&quality

4)Strict quality control system

5)Standard export sea-worthy packing

5. Why choose us?

1).Advantages: We have two production line of PPGI and two lines for the galvanized steel coil, total yearly output is about 500000mt Also we have 56 professional salesperson from three international sales department, a group of technical engineers

And skillful quality control inspector.

2). Special technology support: We have two production line of pre-painted steel coil

And two lines for the galvanized steel coil, total yearly output is about 500000mt. In

Order to meet our customers new requirements, We also can manufacture the special

Products, such as Printed, Filmed, Pressed, Matte steel coil and the full hard G550

Galvanized steel and galvalume steel.

3). Conform the international quality standard: All products for export, according to the

International quality standard of Europe, Japan, Russia and America to produce.

Item: | Galvanized Steel Coils |

Material: | SGCC, SGCH, SPCC, SGCD, DX51D+Z, STO2Z,DX54D,DX51D |

Thickness: | 0.14mm-1.2mm |

Width: | 762-1250mm |

Length: | Coiled or as requested |

Surface: | Galvanized,oiled,chromated |

Application: | Industrial panels, roofing and siding for painting |

Types: | Commercial / Drawing / Deep Drawing / Structural quality |

Zinc coating: | Z40-275g/m2 |

Surface Treatment: | chromed / skinpass/ oiled/slightly oiled/ dry/ anti-fingerprint |

Surface Structure: | zero spangle / minimized spangle / regular spangle/ big spangle |

Coil Weight: | 3-10 ton per coil |

Payment term: | T/T,L/C |

Packing information: | Export standard package :bundled wooden box or be required; The inner size of container is below: 20 ft GP:5.8m(length)x 2.13m(width)x 2.18m(high) about 24-26 CBM 40 ft GP:11.8m(length)x 2.13m(width)x 2.72m(high)about 68 CBM |

Port: | Qingdao,Tianjin port |

Delivery time: | 15-20 days,after we received your deposit |

- Q: How do steel coil manufacturers stay updated with industry trends?

- Steel coil manufacturers utilize various methods to stay informed about industry trends: 1. Attending industry conferences and trade shows allows manufacturers to connect with other professionals, attend seminars and presentations, and learn about the latest trends and innovations in the steel coil industry. 2. Subscribing to industry publications and magazines provides manufacturers with regular updates on trends, market insights, and technological advancements in the steel coil industry. These publications often feature articles and interviews with experts, delivering valuable information to stay updated. 3. Actively participating in online forums, discussion boards, and social media groups dedicated to steel coil manufacturing helps manufacturers stay connected with the industry. These platforms allow them to engage with peers, share knowledge, ask questions, and stay updated on the latest trends. 4. Maintaining close relationships with suppliers and customers enables manufacturers to gain insights into changing market demands, new product requirements, and emerging trends. Suppliers and customers often share information about industry trends and advancements that assist manufacturers in adapting their processes accordingly. 5. Investing in continuous education and training programs for employees ensures that the workforce remains updated on the latest industry trends, technological advancements, and best practices. Prioritizing employee development equips manufacturers with the skills and knowledge necessary to stay ahead of the curve. 6. Allocating resources for research and development activities allows steel coil manufacturers to explore new materials, manufacturing techniques, and technologies. By investing in R&D, manufacturers can stay at the forefront of industry trends and develop innovative solutions that meet evolving customer demands. 7. Staying updated with government regulations, industry standards, and certifications that impact the steel coil industry is crucial. Compliance with these regulations often requires manufacturers to adopt new practices, technologies, or materials, ensuring that they remain up to date with the latest trends and requirements. By actively engaging in these activities, steel coil manufacturers can stay informed about industry trends, emerging technologies, and market demands. This enables them to adapt their processes, products, and strategies to remain competitive and meet the evolving needs of their customers.

- Q: I'm sort of a sword maker. You could say I'm an amateur blacksmith. I want to find a dependable source of high-grade steel. I've made a few blades and from what I know about the difference between true steel and cheap steel, I have yet to work with such. All of the metal I have used could not have been true high carbon spring steel because while they are hard, their properties do not reflect that of true steel. I would sincerely appreciate any guidance on where I could order some fine-quality steel so I could produce a truly fine blade.

- You have already a good answer, but you have to bear in mind that in your work you need to follow the correct procedure for heat treatment. That procedure is dependent on the type of steel you have picked on.

- Q: I found this amazing kid on youtube - is he using nylon or steel strings?(I'm buying my first guitar! helpp)oh and is fingerstyle also possible in steel string guitar? does it hurt?(I might sound really stupid-..)thanks a lot

- In that video, he is using a steel-string acoustic guitar. However, when choosing between a nylon string guitar and a steel string guitar, you must consider a few things. Steel-string guitars are more painful in the beginning for the fretting hand, but that means you'll have more strength in your fingers faster. Nylon-string guitars are easier on the fingers and sound much smoother and calmer than steel-string guitars. Also, nylon-string guitars have a wider neck and that neck meets the body at the twelfth fret, while most steel-string guitars have a thinner neck that meets the body at the fourteenth fret. Have fun with your first guitar! :)

- Q: How are steel coils used in the production of aerospace components?

- Steel coils are used in the production of aerospace components in a variety of ways. One common application is in the manufacturing of structural parts, such as frames, beams, and brackets. Steel coils are often processed into flat sheets or strips, which are then cut and formed into the desired shape for these components. The strength and durability of steel make it an ideal material for these critical parts that need to withstand extreme forces and conditions. Additionally, steel coils are used in the production of engine components, such as turbine blades and combustion chambers. These components require materials with high temperature resistance and excellent mechanical properties. Steel coils are processed and shaped into intricate forms to create these vital engine parts, ensuring efficient and reliable operation. Furthermore, steel coils are used in the production of fasteners, such as bolts, nuts, and screws, which are essential for assembling various aerospace components. The high strength and corrosion resistance of steel make it a preferred choice for these fasteners, as they need to withstand the extreme forces and environments experienced during flight. Overall, steel coils play a crucial role in the production of aerospace components by providing the necessary strength, durability, and reliability required for safe and efficient operation in the demanding aerospace industry.

- Q: How do steel coils compare to other types of metal coils?

- Steel coils are highly regarded for their exceptional strength and durability, making them superior to other types of metal coils. Steel is known for its high tensile strength, allowing it to withstand heavy loads and resist deformation. This makes steel coils ideal for applications that require a high level of structural integrity, such as in the construction and automotive industries. In addition to their strength, steel coils also offer excellent corrosion resistance. Various protective layers, such as zinc or paint, can be applied to steel to prevent rusting and ensure longevity. This makes steel coils suitable for outdoor and marine environments where exposure to moisture and harsh weather conditions is common. Furthermore, steel coils have a diverse range of mechanical properties that can be customized through different manufacturing processes. This allows for the production of steel coils with specific characteristics, including high ductility, heat resistance, or electrical conductivity, to meet the requirements of various industries. When compared to other metal coils, such as aluminum or copper, steel coils often have a lower cost. Steel is one of the most economical metals available, and its abundance in nature contributes to its affordability. This makes steel coils a cost-effective choice for many applications, especially when large quantities are required. Overall, steel coils are distinguished by their exceptional strength, durability, corrosion resistance, versatility, and affordability. These qualities make steel coils the preferred choice for a wide range of industries, including construction, manufacturing, transportation, and energy.

- Q: What are the different types of steel coil packaging materials for export?

- Some of the different types of steel coil packaging materials for export include wooden crates, steel crates, steel frames, steel racks, plastic wrapping, and cardboard boxes. These packaging materials are chosen based on the weight and dimensions of the steel coils, as well as the specific requirements of the export destination.

- Q: Alright, First off i have an old plywood military box with galvanised steel corners, hinges etc (any part that must be strong) and its rusting! Some of the pieces have discoloration (like an oil stain on them) and other parts are full of this metallic dust. 1) Should i remove this box from my room?2) Is there any way or should i remove the powder on the part?3) Does this pose a serious health hazard?4) What are the oil stains?

- Wipe the powder of and the rest should be safe, unless you stub your toe on the rusty metal.

- Q: What are the common methods of cutting steel coils?

- The common methods of cutting steel coils include shearing, slitting, and laser cutting. Shearing involves using a machine with two blades to cut through the coil. Slitting involves passing the coil through a set of rotating circular blades to create narrower strips. Laser cutting uses a high-powered laser beam to cut through the steel coil with precision.

- Q: What are the different methods of protecting steel coils from corrosion?

- There are several methods of protecting steel coils from corrosion, including applying a protective coating, using corrosion inhibitors, implementing proper storage and handling practices, and utilizing galvanization or electroplating techniques.

- Q: Ok.. I was wondering if it's possible for me to recycle baked bean cans (steel)? And if so in Western Australia (that's where I live)?I love baked beans... and I also like skateboarding, so I thought if I kept my baked bean cans, that I could get them recycled somewhere and turn it into something I could skate on (rail, etc.). I'm just curious to know if all this is possible...Cheers. :)

- Most baked beans are cooked with pork and include a piece in the can. Depending on what kind of vegetarian you are, you could eat them and simply remove the piece of pork, or, Bush's has vegetarian baked beans which are obviously cooked without the meat seasoning. They are very good, and of course beans are an excellent and needed source of protein in a vegetarian diet.

Send your message to us

Hot Dipped Galvanized Steel Coil /Pre-painted Galvanized Steel Coil/Pre-painted Steel Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords