Prepainted steel coils Prime quality steel coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,DIN,JIS | Grade: | steel | Thickness: | 0.17-1.5mm |

| Place of Origin: | China (Mainland) | Brand Name: | CNBM | Model Number: | SGCC Q195L, Q235, DX51D |

| Type: | Steel Coil | Technique: | Hot Rolled,hot dip | Surface Treatment: | Coated |

| Application: | Flange Plate | Special Use: | Steel | Width: | 600-1250mm |

| Length: | 2000-6000mm |

Specifications

1.reasonable price

2.reliable quality

3.fast shipment

4.huge production capacity

5.BV,SGS and TUV certificates

Prepainted Steel coil PPGI

| Commodity | Prepanited steel coil |

| Grade | JIS G3302(SGCC), DX51D, EN10142, GB/T2518-2004, ASTM 653 |

| Standard | ASTM, AISI, DIN, GB |

| Types | Commercial / Drawing / Deep Drawing / Structural quality |

| Width | 500/650/726/820/914/1000/1200/1219/1220/1250mm |

| Thickness | 0.16-1.2mm (0.14-0.5mm is the most advantage thickness) |

| Type of coating | Galvanized |

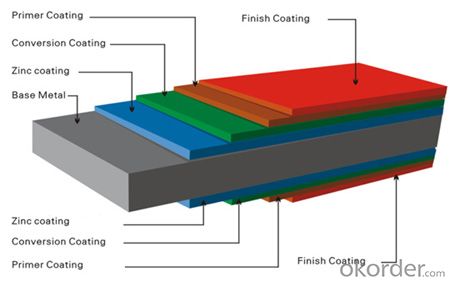

| Zinc / PE coating | Z60-275g/m2 ,12-20μm(top)/7-10μm(bottom) |

| Surface | RAL System as per customers request |

| ID coil | 508mm |

| Coil weight | 4-6MT |

| Package | Properly packed for ocean freight exportation |

| Application | Industrial panels, roofing and siding for painting |

| Payment terms | 30%TT in advance+70% TT or irrevocable 100%L/C at sight |

| Delivery time | 25 days after recepit of 30% TT or L/C |

PACKING

4 eye bands and 4 circumferential bands in steel, galvanized metal fluted rings on inner and outer edges, galvanized metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumference and bore protection

FAQ

We have organized several common questions for our clients,may help you sincerely:

1)How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2)How long can we receive the product after purchase?

In the purchase of product within 20-25 days, we will arrange the factory delivery as soon as possible. The pacific time of receiving is related to the state and position of customers. Commonly 15 to 30 days can be served.

3)Syringes are CE,FDA approved. And we supplied main nations in the world.

- Q: How are steel coils used in the HVAC industry?

- Steel coils are commonly used in the HVAC industry as a key component in air conditioning and heating systems. They are used to transfer heat energy, allowing the system to cool or heat the air efficiently. The steel coils act as heat exchangers, absorbing heat from the air and releasing it into the environment or vice versa. This process helps regulate the temperature and improve the overall performance of HVAC systems.

- Q: How are steel coils used in the manufacturing of lighting fixtures?

- Steel coils are used in the manufacturing of lighting fixtures as they provide a sturdy and durable structure for the fixtures. The coils are typically shaped and formed to create the desired shape and design of the lighting fixture, ensuring its strength and stability. Additionally, the steel coils can be coated or painted to enhance the aesthetics of the fixture, making it more visually appealing.

- Q: What are the different types of steel coatings used on coils?

- There are several types of steel coatings used on coils, including galvanized, galvannealed, and organic coatings. Galvanized coatings involve applying a layer of zinc to the steel surface, providing excellent corrosion resistance. Galvannealed coatings involve a two-step process where the steel is first galvanized and then heated to form an alloyed surface layer, offering enhanced paint adhesion and weldability. Organic coatings, on the other hand, use paints or other protective coatings to provide corrosion resistance and aesthetic appeal.

- Q: How are steel coils used in the production of storage containers?

- Steel coils are commonly used in the production of storage containers as they provide the strong and durable material required to withstand heavy loads and protect the stored items. These coils are cut, shaped, and welded to form the structure of the container, ensuring its strength and stability. Additionally, the steel coils can be coated or painted to enhance their corrosion resistance and improve the container's lifespan.

- Q: How are steel coils used in the production of roofing and siding?

- Steel coils are used in the production of roofing and siding by being processed and formed into flat sheets or panels. These coils are run through a roll forming machine, which shapes them into the desired profile for roofing or siding. The resulting sheets or panels are then cut to size and installed on buildings to provide durable and weather-resistant protection.

- Q: Iron melts faster when there will be low carbon in Iron.During steel making the molten Iron gets purified and alloying being done through the process. How the carbon is being controlled at Iron melting stage and what it is called?

- Steel is usually made in a two-step process. As you may know, carbon, in the form of coke, is added to the iron ore during the initial smelting process. This is the first step. The conversion of iron ore into raw iron is accomplished with a blast furnace. Carbon dissolves with the iron during the smelting process. The amount of carbon in the iron is generally not controlled at this point as this would be too difficult, the excess carbon is removed in the next step. The result is pig iron which is crude iron that has a very high carbon content, and a large amount of impurities. Pig iron is almost as brittle as glass, and it is useless in this form. In most modern steelmaking operations, molten pig iron is tapped from the blast furnace three or four times per day- it is not allowed to cool. The liquid pig iron is carried in ladles directly to a Basic Oxygen Furnace which converts the pig iron into steel. The basic oxygen converter uses a stream of pure oxygen to burn off the excess carbon. Impurities are also burned off, particularly phosphorus, silicon, and sulfur (which damage the steel's properties.) These elements all have a much higher affinity for oxygen than iron does, so the iron itself remains unchanged. Once the carbon content and the impurities are reduced to the desired level. The oxygen is shut off, and the iron has now become steel. At this point other alloying elements may be added, such as chromium, manganese, or molybdenum. These elements improve the steel's properties, but also add to it's price. If necessary, more carbon can be added as well if the carbon content has accidentally dropped too low. Finally, molten steel from the basic oxygen furnace is poured off. It can be cast into ingots, billets, or thin slabs.

- Q: What is the difference between cold rolled strip and cold rolled steel coil?

- Cold rolled steel strip: the width is below 900mm! Cold rolled steel coil: the width is above 1000mm! Materials and purposes are not very different, basically the same!

- Q: How is it used easy 10 points just tell me how its used or any intersting facts this is for my comp science paper lol. I know what the hell does steel have to too do with computers he is a Fg! Please be descriptive THANKS! FAST ANSWERS TOO it 9pm bedtime for a 14 year old lol..

- steel is used for cars and trains. one of the largest steel manufacturers is in my town its called CarTech its in reading pa.

- Q: How are steel coils tested for compliance with industry standards?

- To ensure compliance with industry standards, steel coils undergo a series of rigorous quality control measures. These tests are conducted to verify that the coils meet necessary specifications and are suitable for various applications. Among the primary tests performed on steel coils is dimensional inspection. This entails measuring the thickness, width, and length of the coils to ensure they fall within specified tolerances. Any deviations from the required dimensions may indicate manufacturing defects or potential issues during fabrication. Another crucial test is visual inspection, where trained inspectors meticulously examine the coils for surface defects like scratches, dents, or cracks. Identifying and rectifying these defects is essential as they can impact the performance and durability of the steel coils before they are supplied to customers. Additionally, mechanical properties testing is carried out to assess the strength, elasticity, and toughness of the steel coils. This includes conducting tests for tensile strength, yield strength, and elongation measurements. These evaluations help determine if the coils are suitable for specific applications and if they meet the required performance standards. Furthermore, chemical composition analysis is performed to validate the elemental composition of the steel coils. This analysis is crucial as it ensures that the steel meets the required chemical requirements, including the presence of specific alloying elements. Deviations in composition can significantly affect the overall quality and performance of the coils. Corrosion resistance testing is also of great importance, particularly for coils used in environments with high humidity or exposure to corrosive substances. Coils are subjected to simulated real-world conditions, such as salt spray or humidity chambers, to evaluate their resistance to corrosion. Lastly, various non-destructive testing techniques, including ultrasonic testing and magnetic particle inspection, are employed to detect internal defects or discontinuities in the steel coils. These tests assist in identifying any hidden flaws that could compromise the structural integrity of the coils. In summary, steel coils undergo a comprehensive array of tests to ensure adherence to industry standards. By conducting these tests, manufacturers can guarantee that the coils meet the required specifications, thereby providing customers with high-quality products tailored to their specific needs.

- Q: How are steel coils used in the production of roofing panels?

- Steel coils are an essential component in the production of roofing panels. These coils, typically made of galvanized or coated steel, serve as the base material for manufacturing durable and high-quality roofing panels. Firstly, the steel coils are processed through a series of machines in a production facility. These machines flatten, clean, and shape the coils into the desired dimensions and profiles for the roofing panels. The process ensures that the steel coils are uniform in thickness and free from any impurities or imperfections that could compromise the integrity of the final product. Once the steel coils are prepared, they are then fed into a roll forming machine. This machine gradually bends and shapes the steel coils into the specific design and size required for the roofing panels. The roll forming process provides the panels with their distinctive corrugated or standing seam profiles, which enhance their strength and ability to withstand various weather conditions. After the roll forming process, the steel coils are cut into individual roofing panels of the desired length. These panels are then further processed to add additional features, such as coatings or finishes, for improved protection against corrosion and aesthetic appeal. The steel coils are often coated with protective layers, such as zinc or paint, to enhance their resistance to rust, UV rays, and other environmental factors. Finally, the roofing panels are packaged and shipped to construction sites or distributors for installation. The use of steel coils in the production of roofing panels ensures that the final product is strong, durable, and long-lasting. Steel is renowned for its high tensile strength, which makes the roofing panels capable of withstanding heavy loads, strong winds, and other external forces. In summary, steel coils play a crucial role in the production of roofing panels. They are transformed into the desired dimensions and profiles through a series of manufacturing processes, ensuring uniformity and quality. The resulting roofing panels are not only aesthetically pleasing but also highly durable, providing superior protection and longevity for buildings.

Send your message to us

Prepainted steel coils Prime quality steel coils

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords