PREPAINTED STEEL COIL JIS G 3312 CGCC WITH HIGH QUALITY

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25.00 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

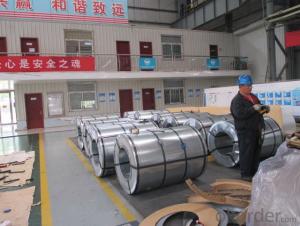

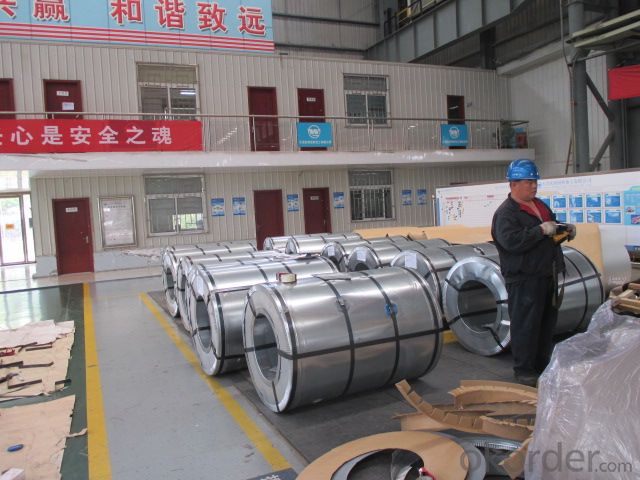

PREPAINTED STEEL COIL

Packaging & Delivery

Packaging Detail: seaworthy export package

Delivery Detail: on request

Specifications

1. more than 10 years’ experience on this field

2. advanced equipments

3. competitive price

4. soonest delivery

Product Description :

Commodity

PREPAINTED STEEL COIL

Technical Standard: JIS 3312

Grade:CGCC

Types:Commercial / Drawing / Deep Drawing / Structural quality

Width: 900mm/1000mm/1219mm/1200mm/1220mm/1250mm

Thickness: 0.2mm~4.0mm

Type of coating: galvanized

Zinc coating: Z40-275g/m2,Z40-Z450g/m2

ID coil: 508mm or 610mm

Coil weight: 3-10/MT per coil

Package: Properly packed for ocean freight exportation in 20''container

Application:: home appliances, constructions, building, machineries

Our Advantages :

1. Expertise:

More than 10 years of manufacture: we know how to properly handle every step of production.

2. Competitive price:

We can offer competitive prices to our customers.

3. Accuracy:

We have excellent technicians and leaders, which can ensure our products are exactly what you want.

4. Materials:

All galvanized steel coils are made of high-quality raw materials.

5. Certificate:

Our products are certified by ISO9001.

6. Productivity:

We have large-scales of production lines,, which can guarantee all your orders will be finished in earliest time.

Hr CGL Technical Process:

Coil loading-> uncoiling-> cutting-> welding-> entry accumulator-> Heating and deoxidization-> galvanizing-> air cooling->water quenching-> air dryer-> tension leveler-> Passivation->air dryer->exit accumulator-> oiling-> cutting-> recoiling->coil unloading-> packing

The furnace heating style: improved Sendzimir heating technology

Hourly output: max.76.3t/h

Process after coating: tension leveling, Passivation or oiling

Our Service

Our quality

Test Equipments of Prepainted Galvanized Steel Coil : Salt-spray tester; Atomic absorption spectrophotometer; Rockwell typer hardness tester; Tensile test machine; Metrohm titration; Laboratory Bend test machine.

Our packing

Properly packed for ocean freight exportation in 20''container, galvanized metal fluted rings on inner and outer edges, galvanized metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumference.

R&D department

R&D department concentrates on researching and developing reliable products with best quality. The quality department test and control every process of production to guarantee the best quality of product

- Q: We just installed a stainless steel electric stove, what is the best way to keep it clean and shiney?

- Contact a sanitary supply company for a product to maintain stainless steel.

- Q: How are steel coils processed for painting or coating?

- Steel coils are processed for painting or coating through a series of steps. Firstly, the coils are cleaned to remove any dirt, oil, or scale using various methods like acid pickling or mechanical cleaning. Then, a primer or chemical treatment is applied to enhance the adhesion of the paint or coating. Next, the coils are dried to remove moisture and ensure proper adhesion. Finally, the paint or coating is applied to the coils using methods such as coil coating or electrostatic spraying, and then the coated coils are cured to achieve the desired finish and durability.

- Q: i am working in a firm that deals with steels.. so it is necessary for me to understand the chemistry of the steels from their names so that i need not memorize all the grades with their metallury.. where can i find information about this nomenclature ? please help

- For steels with a four number code like 1020, 4140 ect the first two digits are the alloying information. I think you need to memorise those. 10 steels are plain carbon steel with no alloying. 41 steels are chrome-molly. The third and forth digits are the carbon content. 1020 is 0.2% Carbon, 4140 is 0.4% carbon. I don't know if there is a system to stainless steels.

- Q: What are the cost implications of using steel coils in manufacturing?

- The cost implications of incorporating steel coils into the manufacturing process can vary based on multiple factors. To begin with, the overall manufacturing expenses can be significantly affected by the cost of purchasing the steel coils themselves. Steel prices are influenced by various factors, including supply and demand, global market conditions, and any tariffs or trade regulations in place. Fluctuations in steel prices directly impact the cost of acquiring steel coils, which, in turn, affects the overall manufacturing cost. Furthermore, transportation costs can be influenced by the size and weight of the steel coils. Due to their heaviness and bulkiness, steel coils often incur higher shipping expenses as they require increased transportation resources. Additionally, shipping costs can be influenced by the distance between the steel supplier and the manufacturing facility. Moreover, the manufacturing costs can be influenced by the processing and transformation of steel coils into finished products. Depending on the desired end product, additional steps such as cutting, shaping, welding, or coating may be necessary. These supplementary processes require specialized machinery, skilled labor, and extra materials, all of which contribute to the overall manufacturing expenses. Considering the quality and durability of the steel coils is also essential. Although using high-quality steel coils may initially result in higher costs, it can lead to long-term savings by reducing the need for repairs or replacements. Furthermore, it is crucial to consider any regulatory or compliance requirements associated with the use of steel coils in manufacturing. Certain industries may have specific standards or certifications that need to be met, resulting in additional costs for testing, inspections, or compliance procedures. Lastly, it is important to acknowledge the potential cost savings that can be achieved through the utilization of steel coils in terms of efficiency and productivity. Steel coils are often preferred in manufacturing due to their strength, durability, and ease of fabrication. These characteristics can lead to improved production processes, reduced waste, and higher overall output, which can offset the initial cost of using steel coils. In conclusion, the cost implications of using steel coils in manufacturing are influenced by several factors, including steel prices, transportation costs, additional processing requirements, quality considerations, regulatory compliance, and potential productivity gains. A careful analysis and consideration of these factors are crucial for understanding the overall cost impact on manufacturing operations.

- Q: I worked REALLY HARD basically begged my dad to let me stretch my ear lobe piercings. He finally said yes, as long as I don't pass 2g. c: So, we went to Hot Topic to buy tapers, but I don't know if I should get Steel or Acrylic tapers. Which ones are better to start off with?

- Steel

- Q: Basically when i'm older, my dream Job would be, to be to start a steel mill, I've always loved the idea of working in Business and investing in things has always been a hobby of mine. i play games where u invest and make money. all i need is some facts about starting a steel mill?What requirements i need,- How time consuming is it,- How easy is it,- How to get started,- The Perks,- The downsides..how much would it cost to start one, like land, place, iron etc, to get started? also i would need a bank loan, how much money will the bank give me ? 80%??

- Typically, steel mills are worth $20 million to $200 million and are owned by large corporations. Your best bet to own one would be to take over a corporation that already has one. That way you have all the supply lines, customers, experts and other workers already there, too. Stick with investing in going concerns, so you don't need to be an expert in each business to build it up. Get them ready made, learn the details from the people already doing it, then work out ways to improve it. Do not get tempted to borrow even 10c from the scammers who have answered your question. Start saving your real money, reading the financial news, and making small real investments in real stocks.

- Q: Why cold rolled stainless steel sheet is lower than cold rolled stainless steel coil?

- Hello! The reason is: 1. cold rolled flat plate is Kaiping;2. cold-rolled plates are negative tolerances.

- Q: I feel really stupid asking this question but i feel like a put metal/steel strings on my classical guitar how do you tell the difference?

- you do NOT want to put steel strings on a nylon string guitar, it will ruin it. It does get a little confusing. With steel strings, all 6 strings are metal. (usually steel, but not always, nickel, copper may be used too) And they use a steel core. with nylon strings, the high 3 strings, are obviously nylon/plastic. the 3 bass strings look metal, but they have a silk type core, with metal wrapped around it. The steel strings have a LOT more tension,, they can break the plastic tuners, beak the nut, pull the top up, and pull the bridge off, If you're not sure yet, have a real music store explain it, not a toy store, or costco or walmart.

- Q: Why do we galvanise steel? Galvanised steel is steel coated with zinc.

- We galvanize steel to protect and prevent steel from rusting or corrosion. Rusting, for the most part is a layman's term that has been used exclusively to describe the chemical OXIDATION reaction of steel or iron with oxygen forming a reddish brown substance called rust. Zinc metal coating also oxidizes but does not form the reddish brown rust. Instead, it forms an oxide, just like the rust, which is iron oxide. The protection created by zinc is because it is more reactive to oxidizers, than steel or iron. Thus, the oxidizer will react with Zinc first before it will react with Iron, hence protecting iron. If the zinc is fully reacted then iron is next. BUT, the zinc oxide formed on the surface of the steel or iron is no longer reactive to oxygen and also creates a good physical barrier so that oxygen will not have chance to even have contact with the underlying steel. Isn't that neat! Here is chemistry at one of its useful best.

- Q: What is the role of steel coils in the electrical industry?

- Steel coils play a crucial role in the electrical industry as they are used in the manufacturing of various electrical components and equipment. These coils are typically made of high-quality steel and are used in transformers, motors, generators, and other electrical devices. They provide structural support and act as a core for the electromagnetic field required for the functioning of these devices. Additionally, steel coils are also used in the production of magnetic cores, which are essential for efficient energy transfer and storage in electrical systems. Overall, steel coils are integral to the electrical industry, enabling the efficient and reliable operation of electrical equipment.

Send your message to us

PREPAINTED STEEL COIL JIS G 3312 CGCC WITH HIGH QUALITY

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25.00 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords