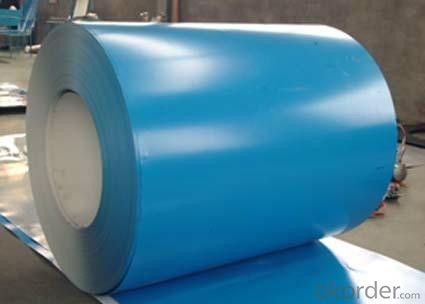

Prepainted Rolled steel Coil for Construction roofing use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prepainted Rolled steel Coil for Construction Roofing

Description of Prepainted Rolled steel Coil for Construction Roofing

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

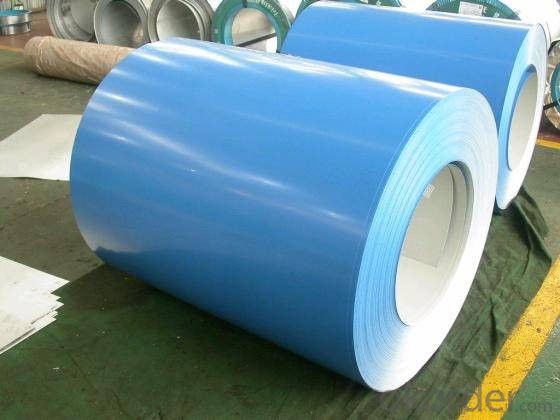

Main Feature of Prepainted Rolled steel Coil for Construction Roofing

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Prepainted Rolled steel Coil for Construction Roofing

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Rolled steel Coil for Construction Roofing

Product | Prepainted Rolled steel Coil for Construction Roofing |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.2-3.0mm |

Width | 600-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ40-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM |

Coil weight | 10MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prepainted Rolled steel Coil for Construction Roofing

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: All the steel straps that secure my deck and stair 6x6 posts to the concrete piers have some rust on them. Had bought a rust reducer to spray on them and repaint. As I went to do this I found that one of them is on its last legs, with the steel rusted through and bubbling up all up the sides of the straps. Since this is the end post on a row of 3 deck support posts, I was thinking of removing as much rust as possible, then paint with Rustoleum and cover lower post with something to keep water away from post and pier in the future? Was thinking of something removeable so I could check on it for further rusting. What do you folks with building experience think of this? Thanks.

- Sorry troll, doctors don't give a tetanus shot just because you came into contact with rusty metal. The belief that you need a tetanus shot for stepping on a rusty nail is not quite accurate -- it's not the rust that prompts the shot, it's the fact that the nail was on the ground and dirty.

- Q: What temp does fire have to be to melt steel?

- You need about 2800 degrees to melt steel.

- Q: What are the different types of corrosion protection methods used for steel coils?

- There are several types of corrosion protection methods used for steel coils. These include applying a protective coating such as paint or zinc, using corrosion inhibitors, employing cathodic protection techniques, and utilizing barrier protection methods like galvanizing or metallizing. Each method has its own advantages and is chosen based on the specific needs and requirements of the steel coils.

- Q: How are steel coils processed at the steel service centers?

- Steel service centers process steel coils through a series of steps to transform them into finished products that meet the specific requirements of customers. The process typically begins when the steel coils arrive at the service center. These coils are usually large and heavy, and they may have been produced by a steel mill or imported from overseas. Upon arrival, the steel coils undergo a quality inspection to identify any defects and ensure that only high-quality coils are used in the production process. After inspection, the coils are stored in a warehouse until they are ready for processing. Next, the steel coils are uncoiled to create flat sheets of steel. This can be done manually or using automated machines, depending on the size and thickness of the coils. The uncoiled steel is then leveled to remove any residual stress and ensure a flat and consistent surface. Once leveled, the steel sheets go through various processes based on the desired end product. These processes may include cutting, shearing, slitting, and forming. Cutting and shearing involve shaping the steel sheets into specific sizes or shapes. Slitting involves cutting the steel into narrow strips, while forming involves bending or shaping the steel. After the desired processing operations are completed, the steel sheets are often treated with surface finishes to enhance their appearance or protect them from corrosion. These finishes may include painting, coating, or galvanizing. Finally, the processed steel sheets undergo another quality inspection to ensure they meet the required specifications. They are then packaged and prepared for shipment to customers in industries such as construction, automotive, or manufacturing. Overall, the processing of steel coils at steel service centers involves a combination of inspection, uncoiling, leveling, cutting/shearing/slitting/forming, surface finishing, quality control, and packaging. This process allows for the transformation of steel coils into finished products that are customized to meet the specific needs and requirements of customers.

- Q: How are steel coils used in the manufacturing of HVAC ductwork?

- Steel coils are used in the manufacturing of HVAC ductwork as they provide the necessary strength and durability required for the ductwork. These coils are typically processed through a roll-forming machine, which shapes them into the required ductwork profile. The steel coils are then cut to the desired length, welded or joined together, and finally, coated to prevent corrosion and improve the overall performance of the ductwork.

- Q: Can steel coils be coated with fluorescent materials?

- Yes, steel coils can be coated with fluorescent materials.

- Q: Can steel coils be stored outdoors?

- Yes, steel coils can be stored outdoors. However, it is important to protect them from exposure to moisture and extreme weather conditions, as these can cause corrosion and damage to the coils. Proper covering or shelter should be provided to ensure their longevity and quality.

- Q: Hello. right now i have been playing electric and acoustic guitar for 6 years. I currently became very interested in learning the pedal steel guitar. I will be teaching myself so is it really hard to learn? Are there a lot of songs online that could give me tabs? Basically im asking if it is worthwhile to spend a lot of money. I dont want it if there are only 3 songs im gona learn. im up for the challenge im just curious how hard it was to learn. thanks for your help.

- The okorder /... Beware of eBay deals unless you know what you're buying. To start, you should get a 10-string single neck with 3 pedals and 4 levers. Some of the student models don't have as many levers and aren't capable of all the changes you need. Stay away from the ShoBud Maverick...you'll outgrow it in a couple of months. Often it makes more sense to buy a used professional model...you'll eventually need one, and they hold their value better than a student model. You'll also need a volume pedal, bar, thumb and finger picks. For now, your guitar amp will be ok. Playing the guitar: There are several tunings and lots of different combinations of levers, but the basic guitar is a 10 string E9 tuning. It's almost an open E but with a few extra notes. The pedals and levers raise and lower the pitch of selected strings. Chord changes are made by moving the bar and pressing pedals and levers. The volume pedal helps you swell and sustain notes. Steel has it's own unique tablature which reflects all these changes. If you have any other questions, feel free to email me or just join the PSG forum and ask there.

- Q: How are steel coils used in the production of electrical enclosures?

- Steel coils are used in the production of electrical enclosures as they are shaped and formed into sheets, which are then cut, bent, and welded to create the enclosure's structure. The steel coils provide the necessary strength and durability required to protect the electrical components inside the enclosure while also offering resistance to various environmental factors such as moisture, heat, and impact.

- Q: How long does the coating on steel coils last?

- The lifespan of the coating on steel coils can vary depending on various factors such as the type of coating, environmental conditions, and maintenance. However, on average, a well-maintained coating on steel coils can last anywhere from 10 to 30 years.

Send your message to us

Prepainted Rolled steel Coil for Construction roofing use

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords