Prepainted Rolled Steel Coil for construction Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prepainted Rolled steel Coil for Construction Roofing

Description of Prepainted Rolled steel Coil for Construction Roofing

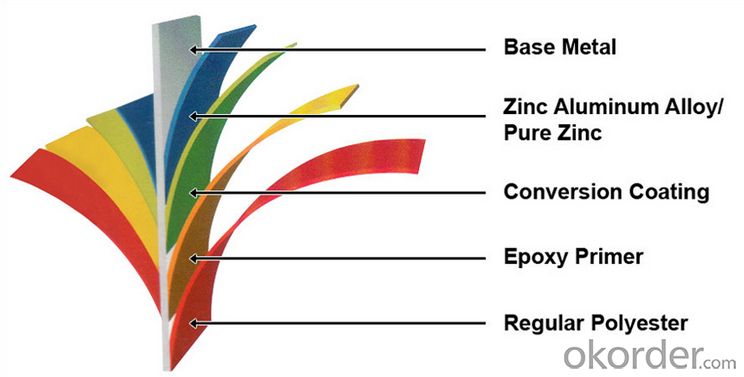

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Prepainted Rolled steel Coil for Construction Roofing

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

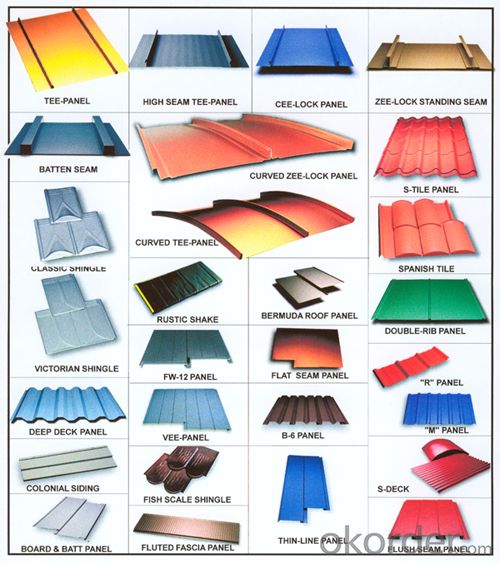

Applications of Prepainted Rolled steel Coil for Construction Roofing

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Rolled steel Coil for Construction Roofing

Product | Prepainted Rolled steel Coil for Construction Roofing |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.2-3.0mm |

Width | 600-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ40-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM |

Coil weight | 10MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prepainted Rolled steel Coil for Construction Roofing

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How do steel coils impact the environment?

- Steel coils impact the environment in several ways. Firstly, the production of steel coils requires large amounts of energy and resources, leading to increased greenhouse gas emissions and depletion of natural resources. Additionally, the manufacturing process generates air and water pollution, contributing to environmental degradation. Furthermore, the disposal of steel coils after use can result in land pollution if not properly managed. Overall, the production and use of steel coils have a significant environmental footprint.

- Q: i am debating weather to get the hercules rmx or the steel and from what i have read, the only differences between them is the rmx has a sound card (built in interface-to connect to the computer, correct me if im wrong) and that the steel has more effects. however, i cannot find out which effects it has so it would be a big help if someone can answer this for me.thanx

- I guess that since Steel doesn’t have headphones connection and a built-in soundcard, one won’t be able to play a track on one deck and prelisten the track on the other without using an external usb soundcard, right? I was wondering what’s the point in releasing a product like this if you also have to buy a bunch of equipment to be able to do sth “fondamental”: play while preparing your next song. However since the steel is meant for DJ’s who already have a great soundcard, but I don’t see why a Steel+sound card is ONLY for pro’s. Yes it’s designed for pro’s but you can use it as a beginner. Some consoles you also need to consider: Hercules Steel/RMX, Numark OMNI/Steath. It's all personal decision. Peace, Love Happiness

- Q: can anyone help me to find any webpage about lists/types of stainless steel?

- Types of stainless steel There are over 150 grades of stainless steel, of which fifteen are most common. The AISI (American Iron and Steel Institute) defines the following grades among others: - 200 Series—austenitic iron-chromium-nickel-manganese alloys - 300 Series—austenitic iron-chromium-nickel alloys Type 301—highly ductile, for formed products. Also hardens rapidly during mechanical working. Type 303—free machining version of 304 via addition of sulfur Type 304—the most common; the classic 18/8 stainless steel Type 316—Alloy addition of molybdenum to prevent specific forms of corrosion - 400 Series—ferritic and martensitic alloys.

- Q: What are the dimensions of steel coils used in the automotive industry?

- Steel coils used in the automotive industry come in various dimensions, which are determined by the specific application and requirements. Normally, the thickness of these coils falls between 0.5mm and 3mm, while the width ranges from 500mm to 2000mm. The length of the coils is subject to variation, depending on the production process and customer specifications. Furthermore, the weight of the coils can range from a few hundred kilograms to several tons. It is worth mentioning that these dimensions serve as general guidelines and may differ based on the particular needs of the automotive manufacturer.

- Q: What are the key factors affecting the strength of a steel coil?

- The key factors affecting the strength of a steel coil are the composition of the steel, the heat treatment process, the rolling and cooling processes, and the presence of any impurities or defects in the coil.

- Q: How are steel coils used in the production of pressure vessels?

- Steel coils are used in the production of pressure vessels as they are rolled into cylindrical shapes, which serve as the main structural component of the vessel. The coils are formed and welded together to create a strong and durable container capable of withstanding high pressures.

- Q: How are steel coils used in the manufacturing industry?

- Steel coils are used in the manufacturing industry for a variety of purposes, including the production of various steel products such as automotive parts, construction materials, household appliances, and machinery components. These coils are often processed and formed into desired shapes through techniques like cutting, bending, and welding to create finished products that are durable, strong, and suitable for various applications in different sectors.

- Q: What are the main factors that affect the strength of steel coils?

- The main factors that affect the strength of steel coils are the composition of the steel, the manufacturing process, and the heat treatment applied.

- Q: iam talking abt carbon steel of composition:-C=0.15wt% Mn=0.60wt% P=0.035wt% S=0.04wt% Cu=0.20 (min)wt%....

- The composition you mention is not a low carbon steel.The carbon and manganese content are high enough to mean that the crystal grain size will be small. A very large grain size is needed in steels for transformers,motors etc.The large grain size and lack of carbides in low silicon steels for magnetic purposes allows the easy movement of magnetic domain walls.Transformer steels typically have a carbon content of about 0.003% and 3.5%Si with the phosphorus and sulphur at a tenth of the levels you mention.The high Si content increases the electrical resistivity of the magnetic core and reduces the power loss from eddy currents(the core metal has voltages generated in it by the changing magnetic fields) and the power lost in eddy currents heats up a transformers core so it needs extra cooling;the loss is inversely proportional to the resistivity and 3.5%Si increases resistivity of iron by a very large amount.The presence of high silicon with ultra low carbon and manganese level allows the soft magnetic steels to be annealed at very high temperatures(850 to 1100deg C)without a phase change so that the crystals have 10,000 to 10,000,000 times the volume of the crystals in heat-treatable (Just)steel you mention.Fine for playing with and demonstrating electromagnetism but not as electrical engineering feedstuff.

- Q: What are chemical properties of high speed steel? Physical properties?What is high speed steel used for? One interesting fact about high speed steel?

- wikipedia: High speed steel (often abbreviated HSS, sometimes HS) is a material usually used in the manufacture of machine tool bits and other cutters. It is often used in power saw blades and drill bits. It is superior to the older high carbon steel tools used extensively through the 1940s in that it can withstand higher temperatures without losing its temper (hardness). This property allows HSS to cut faster than high carbon steel, hence the name high speed steel. At room temperature, in their generally recommended heat treatment, HSS grades generally display high hardness (above HRC60) and a high abrasion resistance (generally linked to tungsten content often used in HSS) compared to common carbon and tool steels. see reference for more info .

Send your message to us

Prepainted Rolled Steel Coil for construction Roofing

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords