Prepainted rolled Steel Coil for construction Roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

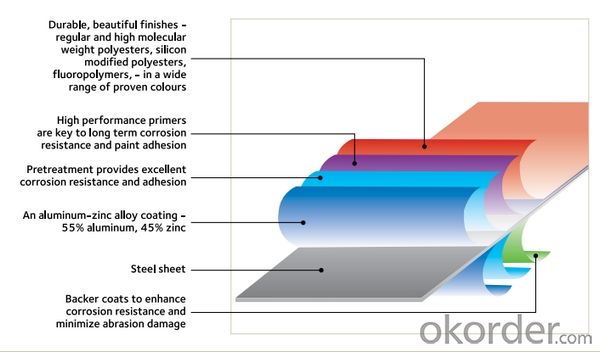

Structure of Prepainted Rolled steel Coil for Construction Roofing

Description of Prepainted Rolled steel Coil for Construction Roofing

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Prepainted Rolled steel Coil for Construction Roofing

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Prepainted Rolled steel Coil for Construction Roofing

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Rolled steel Coil for Construction Roofing

Product | Prepainted Rolled steel Coil for Construction Roofing |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.2-3.0mm |

Width | 600-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ40-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM |

Coil weight | 10MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prepainted Rolled steel Coil for Construction Roofing

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the safety precautions while handling steel coils?

- To prevent accidents and injuries when dealing with steel coils, it is crucial to adhere to specific safety measures. Consider the following key precautions: 1. Personal Protective Equipment (PPE): It is essential to wear suitable PPE, including steel-toed boots, safety glasses, gloves, and a hard hat. This protective gear will safeguard against potential hazards like falling objects, sharp edges, and flying debris. 2. Training and Proper Lifting Techniques: Ensure that workers handling steel coils have received thorough training in safe lifting techniques. This involves lifting with the legs, maintaining a straight back, and avoiding twisting motions. By utilizing proper lifting techniques, the risk of back strains and injuries can be minimized. 3. Secure Storage and Stacking: When storing or stacking steel coils, ensure they are placed on a stable and level surface. Employ appropriate storage equipment like racks or pallets to prevent coils from shifting or falling. Stack the coils securely to prevent toppling or collapsing. 4. Inspection and Maintenance: Regularly inspect steel coils for any defects, such as sharp edges, loose bands, or damaged packaging. Avoid handling coils that appear damaged or unstable. Conduct regular maintenance on equipment like forklifts or cranes used for moving the coils to ensure safe operation. 5. Communication and Signaling: Implement clear communication and signaling protocols among workers involved in handling steel coils. This can involve hand signals or radio communication to coordinate movements and prevent accidents, especially in areas with limited visibility. 6. Load Limits and Capacity: Be aware of the load limits and capacity of the equipment used to move steel coils, such as forklifts or cranes. Overloading equipment can lead to instability, tipping, or collapse, thereby increasing the risk of accidents and injuries. 7. Proper Lashing and Securing: When transporting steel coils, employ appropriate lashing and securing methods to prevent movement or falling during transportation. This may entail using straps, chains, or other restraints to keep the coils securely in place. 8. Emergency Preparedness: Establish an emergency plan in case of accidents or injuries. Ensure that workers are trained in first aid and that emergency response equipment, such as fire extinguishers and first aid kits, are easily accessible. By adhering to these safety precautions, the likelihood of accidents and injuries when handling steel coils can be significantly reduced, creating a safer work environment for all individuals involved.

- Q: How are steel coils used in the aerospace industry?

- Steel coils are used in the aerospace industry for various applications such as manufacturing aircraft components, including structural parts, engine components, and landing gear. These coils are often processed and formed into sheets, plates, or other desired shapes to meet the specific requirements of aerospace engineering. The high strength and durability of steel make it an ideal material for withstanding the demanding conditions and stresses experienced by aircraft during flight.

- Q: Can steel coils be coated with anti-glare materials?

- Yes, steel coils can be coated with anti-glare materials.

- Q: I want to know if Diamond is stronger than Steel.

- Diamond is harder than steel, as diamond can scratch steel, but steel can't scratch diamond. However, I think steel is more structurally stable than diamond. Besides, how can you afford diamond girders, not even mentioning the impossibility of making a diamond that large.

- Q: How are steel coils used in the production of building facades?

- Steel coils are used in the production of building facades as they are rolled into flat sheets and then cut into various sizes and shapes. These steel sheets are then formed, fabricated, and installed to create the outer layer of a building. The steel coils provide strength, durability, and a sleek, modern appearance to the facades, making them an essential component in the construction industry.

- Q: How are steel coils used in the manufacturing of suspension springs?

- Steel coils are used in the manufacturing of suspension springs as they are wound into a specific shape and size to provide the necessary flexibility and resilience required to absorb shocks and vibrations in a vehicle's suspension system. The coils are designed to support the weight of the vehicle and provide a smooth and comfortable ride by compressing and expanding as the vehicle moves over uneven surfaces.

- Q: could anybody tell me the the weight of a cubic metre of mild steel? and where to get this info from?

- i thnk 7.85 the density of ms is 7.85 kg/cm2 and formula is density=mass/volume u have volume=1m3 7.85*1=mass so 7.85 kg

- Q: How are steel coils used in the production of metal cabinets?

- Steel coils are an essential component in the production of metal cabinets. These coils are made from thin sheets of steel that have been wound into a tightly coiled shape. The first step in using steel coils for metal cabinet production is uncoiling them. This is done by unwinding the coil and feeding the steel sheet into a machine that cuts it to the desired length. The length of the sheet will depend on the size and dimensions of the metal cabinet being produced. Once the steel sheet has been cut, it undergoes a process called blanking. This involves cutting out the various panels and parts needed for the metal cabinet, such as the sides, top, bottom, and doors. The blanking process is typically done using a stamping press or a laser cutting machine, which ensures precision and accuracy in shaping the steel sheet. After the blanking process, the individual panels are then formed and shaped using a series of bending and forming machines. These machines apply pressure and force to the steel panels, bending them into the desired shape and creating the necessary angles and curves required for the metal cabinet design. Once the panels have been formed, they are usually joined together using welding or fastening techniques. Welding involves fusing the edges of the steel panels together using heat, while fastening techniques may involve using screws, bolts, or rivets to secure the panels in place. Overall, steel coils play a crucial role in the production of metal cabinets as they provide the raw material from which the individual panels are made. The use of steel coils allows for greater flexibility and efficiency in manufacturing metal cabinets, as it enables mass production and customization of cabinet designs.

- Q: What are the common surface finishes available for steel coils?

- There are several common surface finishes available for steel coils, depending on the desired application and aesthetic requirements. One of the most common surface finishes is hot-dip galvanized, which involves coating the steel coil with a layer of zinc. This finish provides excellent corrosion resistance and is commonly used in outdoor applications where the steel is exposed to moisture and harsh weather conditions. Another popular surface finish is electro-galvanized, which is achieved by applying a thin layer of zinc to the steel coil through an electroplating process. This finish also provides good corrosion resistance but is generally not as durable as hot-dip galvanized. Additionally, steel coils can be coated with a layer of paint or polymer to enhance their appearance and provide additional protection against corrosion. These coatings can be applied in various colors and finishes, such as matte or glossy, to suit specific aesthetic requirements. Furthermore, steel coils can undergo a process called mill finish, which involves leaving the steel in its raw and untreated state. This finish is often used when the steel coil will undergo further processing or coating at a later stage. Other surface finishes for steel coils include stainless steel finish, which is achieved through a passivation process to enhance the steel's resistance to corrosion, and brushed or polished finishes, which are typically used for decorative purposes. Overall, the choice of surface finish for steel coils depends on factors such as the intended use, environmental conditions, and desired appearance, with each finish offering its unique advantages and characteristics.

- Q: Im looking at some knives and am wandering if they use good steel one is this case knife and its 54 dollars Do they use good steel or not Iv never had a good experience with Case but am wandering if they use good steel now? if you all have any other recommendations let me hear them I got my Selection from here so any others wont hurt. so basic break down does case use good steel know?

- Old Case Knives

Send your message to us

Prepainted rolled Steel Coil for construction Roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords