Pre-painted Rolled Steel Coil for Construction Roofing Constrution

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 25 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

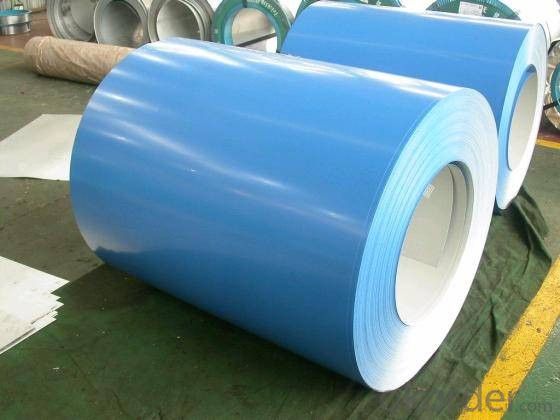

Structure of Prepainted Rolled steel Coil for Construction Roofing

Description of Prepainted Rolled steel Coil for Construction Roofing

Prepainted Rolled steel Coil is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Prepainted Rolled steel Coil for Construction Roofing

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Prepainted Rolled steel Coil for Construction Roofing

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Rolled steel Coil for Construction Roofing

Product | Prepainted Rolled steel Coil for Construction Roofing |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.2-3.0mm |

Width | 600-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | AZ40-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM |

Coil weight | 10MT max |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prepainted Rolled steel Coil for Construction Roofing

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: what do you think about it? Is it a good steel for the money? the knife that i have with that steel is the kershaw chill. good knife for the price

- 8Cr13MoV is a decent blade steel...not a great steel, but about as good as you will generally find without paying much higher prices. It's used by a number of well known knife makers... It's basically equivalent to AUS-8 and will work and hold an edge reasonably well for most basic cutting chores. *************************************** From Wikipedia, the free encyclopedia: 8Cr13MoV, a Chinese stainless steel tempered at the Rc56 to Rc58 range and used in the Tenacious, Persistence, Ambitious, Resilience, Grasshopper, Kiwi3 and Byrd lines of knives. Often compared to AUS-8, but with slightly more Carbon.

- Q: How are steel coils inspected for mechanical properties?

- Steel coils are inspected for mechanical properties using various non-destructive testing methods such as ultrasonic testing, magnetic particle inspection, and eddy current testing. These techniques help to assess the strength, hardness, and other mechanical properties of the steel coils without causing any damage to the material.

- Q: How are steel coils used in the production of electrical motors?

- Steel coils are used in the production of electrical motors as they serve as the core component of the motor's electromagnetic system. These coils are wrapped around an iron core, creating an electromagnetic field when electricity flows through them. This electromagnetic field generates the necessary force that allows the motor to convert electrical energy into mechanical energy, enabling the motor to function and perform various tasks.

- Q: How are steel coils used in the aerospace industry?

- Steel coils are used in the aerospace industry for various applications such as manufacturing aircraft components, including structural parts, engine components, and landing gear. These coils are often processed and formed into sheets, plates, or other desired shapes to meet the specific requirements of aerospace engineering. The high strength and durability of steel make it an ideal material for withstanding the demanding conditions and stresses experienced by aircraft during flight.

- Q: How are steel coils protected against bending and deformation?

- Steel coils are protected against bending and deformation through the use of robust packaging materials, such as wooden crates or steel strapping, which provide structural support and prevent any external pressure from causing damage. Additionally, steel coils may be stored and transported in specialized racks or containers designed to evenly distribute weight and minimize the risk of bending or deformation.

- Q: Why is steel so important? How does it help us in everyday life?

- steel comes from iron. Iron is a natural resource and is abundent in nature. so being able to turn it into steel means it can be used for alllll sorts of things! from buildings, cars, piping and tubes, to washing machines, appliances and many other things. its used in our everyday life and is a great, strong material.

- Q: How are steel coils used in the production of railway tracks?

- Railway tracks rely heavily on steel coils, which are indispensable in their production. These coils, typically made from top-notch steel, are utilized to create the rails that constitute the bedrock of the tracks. The process commences with the unwinding of the steel coils, which are then fed into a sequence of machines that mold and fashion them into the desired rail profile. Initially, the steel coils are passed through a rolling mill, where they undergo gradual flattening and shaping, thereby transforming into elongated steel strips. This technique, known as hot rolling, involves heating the steel to high temperatures to enhance its pliability. The rolling mill exerts substantial pressure on the steel, progressively molding it into the desired rail shape. Once the steel coils have been rolled into the requisite form, they are subsequently severed into individual rail lengths. The length of these rails may vary depending on the specifications of the railway track being produced. The rail lengths then undergo further processing to eliminate any flaws and straighten them out. Following this initial shaping and processing, the rails undergo a series of supplementary treatments. These treatments may entail heat treatment to bolster their strength and durability, as well as various surface treatments to prevent corrosion and wear. Once the rails have undergone all the necessary treatments, they are ready for installation on the railway track. They are laid out meticulously in a predetermined pattern, with each rail securely fastened to the sleepers or ties. The continuous length of steel provided by the coils ensures a seamless and uniform track, enabling trains to travel smoothly and safely. In conclusion, steel coils are crucial components in the production of railway tracks. They are utilized to manufacture the rails that serve as the foundation of the tracks, guaranteeing durability, strength, and a smooth surface for trains to traverse. The use of high-quality steel coils in this process is essential to ensure the safety and efficiency of railway transportation.

- Q: Edward Humphrey wants to know... Can I use steel roofing on an older house?

- steel roofing is a very logical option when considering replacing a residential roof. Keep in mind that in addition to the cost of the actual metal roofing panel, most likely, in order to qualify for the warranties associated with these products, you must also use their accessories and adhere strictly to their installation instructions. If you have a very cut up house, lots of dormers and valleys, etc, the costs to waterproof these areas before installing can get to be costly, but as far as a straight forward reroof over existing substrate, costs are very competitive. As much as I see a lot recommend going over existing shingles, I prefer to strip the existing shingles, and check the sheathing, before waterproofing and roof installation.

- Q: How are steel coils stored and transported?

- Steel coils are typically stored and transported in a horizontal position, either on the ground or on specially designed racks. They are often secured with steel straps or bands to prevent movement or damage during transportation. When being transported, steel coils are typically loaded onto flatbed trucks or shipping containers using cranes or forklifts. The coils are then secured in place with additional straps or chains to ensure stability during transit.

- Q: How are steel coils used in the production of automotive suspension systems?

- Steel coils are used in the production of automotive suspension systems as they provide the necessary support and cushioning to absorb shocks and vibrations while maintaining stability and control. These coils are typically used in coil spring suspensions, where they are compressed and expand to absorb the impact of road irregularities, ensuring a smooth and comfortable ride for the vehicle occupants.

Send your message to us

Pre-painted Rolled Steel Coil for Construction Roofing Constrution

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 25 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords