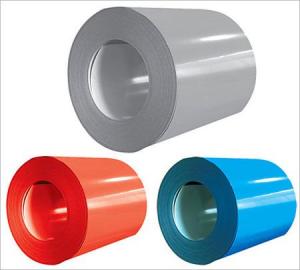

Hot Dip Galvanized Steel in Coil in Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Galvanized Steel Coil gets coated in layers of zinc because rust won't attack this protective metal. The most external layer is all zinc, but successive layers are a mixture of zinc and iron, with an interior of pure steel. These multiple layers are responsible for the amazing property of the metal to withstand corrosion-inducing circumstances. Zinc also protects the steel by acting as a "sacrificial layer." If rust does take hold on the surface of Galvanized Steel Coil, the zinc will get corroded first. This allows the zinc that is spread over the breach or scratch to prevent rust from reaching the steel. For countless outdoor, marine, or industrial applications, Galvanized Steel Coil is an essential fabrication component.

Superiority:

1. Good Resistance to Corrosion

2. Qualified Processing Machinability

3. High Thermal Resistance

4. Excellent Reflectivity

5. Inexpensive and effective enough

6. Can be recycled and reused multiple times

Application:

With excellent cold bending molded manufacturability, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils and widely applied in construction, home appliances, decoration

1. Architecture Roofs and outside walls of civilian and industrial buildings, garage doors, fencings and window blinds

2. Appliances Industry Outer clad sheets for washing machine, refrigerator, television, air conditioner and ventilation system, explosion-proof strip, solar water heater and appliance parts

3. Auto Industry Muffler, heat shields of exhaust pipe and catalytic converter, auto parts & accessories under the frame, signboard in highway

4. Industrial Instruments Electric control cabinet, industrial refrigeration equipment, automatic vending machine

Construction field ,ships building industry ,Petroleum and chemical industries ,war and electricity industries ,food processing and medical industry, boiler heat exchanger, machinery and hardware fields

Electrical Appliance:refrigetator.washer,switch cabinet,etc

Furniture:central heating slice, lampshade, etc

Product Specification:

Material:SGCC,DX51D,Q195

Thickness: 0.3-3.0mm

Width: 600-1500mm

Inner Diameter: 508mm, 610mm

Weight of Steel Coil: 3-15MT

Coating Type: Al-Zn Alloy

Available Dipped Layer: 50-150g/m2

Surface Finish Structure: Normal Spangle & Small Spangle & Zero Spangle

Steel grade & Standard: JIS G3302 SGCC

Spangle: Normal spangle, large spangle, small(min) spangle, zero spangle

FAQ:

1.How about the package for the Hot Dip Galvanized Steel in Coil?

Usually Standard export seaworthy package: waterproof paper+steel trip packed+wooden case seaworthy package

Package:Covered with waterproof-paper, strapped by strips. Standard seaworthy export package:4 eye bands and 4 circumferential bands in steel, galvanized metal fluted rings on inner and outer edges, galvanized metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumference and bore protection.

2. Can I know the production period of the goods?

Usually it need 20 days for 25tons in one container. We can produce 300 tons per day but we need to arrange the production in advance.

3. How about the label, could you make the label according to pour requirements?

Usually we use the MILL label, but if you need special form we can make.

- Q: How are steel coils tested for mechanical properties?

- Steel coils are tested for mechanical properties through various methods, including tensile testing, hardness testing, and impact testing. Tensile testing involves subjecting a small sample of the steel coil to a controlled force, measuring the amount of force required to deform or break the material. Hardness testing determines the resistance of the steel to indentation or scratching, providing insights into its strength and durability. Impact testing assesses the ability of the steel to withstand sudden loads or shocks by striking a sample with a pendulum and measuring the energy absorbed during fracture. These tests help evaluate the quality and suitability of steel coils for specific applications.

- Q: How are steel coils used in the production of electrical appliances?

- Steel coils are used in the production of electrical appliances as the core component for electromagnets. These coils are wound around a metal core and when an electric current passes through them, they create a magnetic field which is essential for the functioning of various electrical components such as motors, transformers, and solenoids.

- Q: What is the minimum order quantity for steel coils?

- The minimum order quantity for steel coils can vary depending on the supplier and specific product requirements. It is best to consult with the supplier or manufacturer directly to determine their minimum order quantity.

- Q: I want to buy steel. My problem is i purchase it from a middle man, so i need to know what MIld steel is. What it's real name or specifications is/are. I dont want to end up purchasing Black steel or other stuff i can sell or use...

- Mild okorder /... Seamless usually refers to a method for making tubing, as opposed to the alloy of steel. Seamless tubing is usually drawn, rather than made from a sheet welded into the form of a tube.

- Q: What are the main factors to consider when selecting a steel coil supplier?

- When selecting a steel coil supplier, the main factors to consider are the supplier's reputation and reliability in delivering high-quality products, their ability to meet your specific requirements such as coil size, grade, and coating, their competitive pricing and payment terms, their capacity and ability to handle your required quantity, and their customer service and responsiveness to your needs.

- Q: How are steel coils used in the production of electrical wiring?

- Steel coils are used in the production of electrical wiring as a core material for the conductors. The steel coils are typically shaped into a cylindrical form and coated with an insulating material. This helps in providing structural support to the wiring and also enhances its conductivity and durability.

- Q: What are the different types of coatings applied to steel coils?

- There are multiple types of coatings that can be applied to steel coils, including galvanized coatings, which involve applying a layer of zinc to prevent corrosion; organic coatings, such as paints or lacquers, which provide protection and enhance aesthetics; and metallic coatings, like aluminum or tin, which offer corrosion resistance and improved appearance.

- Q: What are the typical dimensions of a steel coil?

- The typical dimensions of a steel coil can vary depending on its specific application and industry. However, common dimensions for steel coils include a width ranging from 0.5 inches to 72 inches, and a thickness ranging from 0.010 inches to 0.625 inches. The inner diameter of the coil is usually between 16 inches and 24 inches, while the outer diameter can range from 48 inches to 72 inches.

- Q: Aluminum alloy rolling doors and color steel shutter door that good

- The material and structure design Aluminum Alloy rolling shutter door out of the ordinary, can effectively prevent glare and ultraviolet radiation, sunlight greenhouse effect on indoor has completely solved, applicable to all kinds of changes in climate and weather, has a long-term protective effect on indoor environment, tests show that the shutter doors and windows to keep out sunshine rate to 100%, the the rate can reach more than 95% block temperature.

- Q: How are steel coils inspected for uniformity?

- Steel coils are inspected for uniformity through visual examination and various non-destructive testing techniques. These include measuring the dimensions and weight of the coils, checking for any surface defects or damages, and conducting magnetic particle or ultrasonic testing to detect any internal flaws or irregularities. Additionally, the coils may undergo chemical composition analysis to ensure uniformity in the steel's properties.

Send your message to us

Hot Dip Galvanized Steel in Coil in Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords