Prepainted Galvanized Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

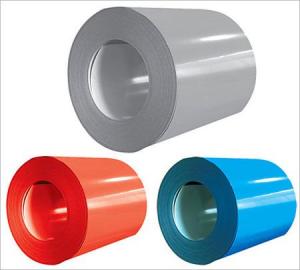

Prepainted Galvanized Steel

With galvanized steel as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

Brand Name: HBSTEEL

Specifications OfPrepainted Galvanized Steel

Thickness 0.20-1.2mm (BMT) Width 600-1250mm |

Zinc Coating 100-275g/m2 |

Color According to RAL color fan or as per request |

Internal Diameter 508mm or 610mm |

Coil Weight 3-6MT |

Quality Commercial and structural quality |

Paint Polyester paint for topside, epoxy for reverse |

Standard JIS G 3312, ASTM A755M, EN 10169 |

Base Steel Grade SGCC,SGCD,DX51D+Z,DX52D+Z;S200GD,S220GD,S280GD,S350GD,CS,FS,SS |

Chemical Composition Of Prepainted Galvanized Steel

C | Si | Mn | P |

0.04-0.06% | 0.01-0.03% | 0.18-0.22% | 0.014-0.016% |

Technical Data Of Prepainted Galvanized Steel

Yield Strength | (Mpa) 280-320 |

Tensile Strength | (Mpa) 340-390 |

Elongation | 20%-30% |

Reverse Impact | 9J |

T-bending | ≥2T |

Pencil Hardness | ≥2H |

Duration Of Salt Spray Test | 500 H |

Bending At 180 Degree | No crack, purling and fraction |

Applications OfPrepainted Galvanized Steel

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making steel roofing,insulation panel, corrugate sheet, facade wall,shutters,T-bar and home appliance.

Production Flow Of Prepainted Galvanized Steel

Production flow of hot sell prepainted galvanized steel include dual uncoiler,stitcher, bridles, entry accumulater, degreasing & chemical section, prime coater, prime oven, prime water quench, finish coating, finish back coater, finish oven, finish water quench, exit accumulater and recoiler.

- Q: I want to buy a chain that will last a long time and that i can wear ALL the time.What are the disadvantages to stainless steel jewelry?Does it look as good as silver?Is there much diference in apperance?

- All of I know are stainless steel advantages. it won't stain, corrode, or rust easily. And it keeps its good-looking shine even for many years.

- Q: I am buying my boyfriend a steel guitar for our one year anniversary and I was curious what brand or company I should look into. I want something high quality yet traditional. Money is not really an issue but I don't exactly want to spend an arm and a leg either.Thank you in advance!

- Did Steel Guitar stand for guitar string ? If yes, there's many brand provide quality guitar string and also be famous brand. you can buy such as D'addario, Errnie ball, GHS, Blue Steel. One more tips, for standard string gauge, if you want to surprise your boyfriend, buy .9 or .10 gauge set. This string set suitable for standard guitar, He'll be more happy if you give him 1 pack of string, buy if it over your price range, just 1 set is ok, haha. Happy Anniversary, Es. ;)

- Q: What are the challenges in coil blanking for high-strength steel?

- Some challenges in coil blanking for high-strength steel include the increased hardness and strength of the material, which can lead to greater wear and tear on cutting tools. Additionally, high-strength steel may have less ductility, making it more prone to cracking or breaking during the blanking process. The higher tensile strength and spring-back characteristics of the steel also require precise control and adjustment of blanking parameters to ensure accurate and consistent part dimensions.

- Q: How are steel coils used in the manufacturing of agricultural trailers?

- Steel coils are used in the manufacturing of agricultural trailers to provide strength, durability, and stability to the trailer's frame, ensuring it can withstand heavy loads and harsh working conditions. These coils are typically shaped and welded to create the trailer's structural components, such as the chassis, sidewalls, and flooring. Additionally, steel coils can be cut and formed into various parts, including axles, suspension systems, and hitch assemblies, to further enhance the trailer's performance and functionality in agricultural operations.

- Q: How are steel coils labeled and identified?

- Steel coils are typically labeled and identified using various methods such as tags, stickers, or printed markings. These labels usually contain important information including the coil's dimensions, weight, grade, manufacturer, and any specific customer requirements. Additionally, unique identification numbers or barcodes may be used for easy tracking and inventory management.

- Q: Building the bulwurk, general use on trawlers. What kind of steel is best suited.

- How big is your trawler going to be and what use, The ones you see off the Alaska Coast or a Gulf Coast Shrimper? My preference in today's economy would not make sense and that is Aluminum.....not steel at all, maybe even Fiberglass, but $$$$ talk so Steel is cheaper, but you need to know what you are doing. The designer of the hull should have specified the right /preferred grade. It today's world there are many more choices available. You use a mild steel, most often grade A or B, but some applications call for grade D. Check your blue prints and list of materials. Edit. Ok I understand. There are 2 ways to go. One is use a relatively cheep steel and use higher cost epoxy primers and paint, often requiring special surface preparation just before priming, or two, using a much higher cost steel with more chrome and nickel in it. Grades that begin with #3xxx These are weldable with rods that are available, and can be welded directly to mild steels. However these are 3X the cost. If your a Shrimper, I'm guessing gulf coast. I worked with several boat yards in the 70's installing spray urethane foam for insulating there holes. So I've been around lots of small yards from Florida to Texas. I'd call the nearest steel warehouse and ask what they would recommend. You might find what you want at a scrap yard. I've lucked out several times picking up 1/4 plate scrap$ and I'd bet the scrapyard guy would know just what you need. I know there are places to get what you need in Mobile and New Orleans. Good luck!

- Q: What is the minimum diameter of a steel coil?

- The minimum diameter of a steel coil depends on various factors such as the thickness of the steel, the type of coil, and the intended use. However, it is generally recommended to have a minimum diameter of around 3 times the thickness of the steel for optimal performance and to prevent damage to the coil during handling and transportation.

- Q: I would like to buy a new cold steel recon 1 folding knife. My concern is the knife is made in Taiwan, will the quality of blade/overall make is lower quality compare with those made in US/JAPAN? The plan is use as an EDC, any good suggestion with similar style? Most important to me is reliability, 2)sharpness, 3) maintance than 4)cost. Anyone can point me into right direction? Please share, Thanks in advance.

- Cold okorder /

- Q: I juuuust got a new stainless steel sink only 5 months ago, and it already has a couple rust spots on it.What caused this?!

- Use a soft cloth or nylon sponge and a little bit of detergent on the spot. Do not use bleach, chlorine or otherwise. If this does not work, try a little baking soda. Always rince out the sink after you use it, soap film can leave a rainbow looking mark in the stainless steel. I take everything out of the sink after I wash dishes. I use a small amount of veg oil on a paper towel to shine up the sink.

- Q: We all know that when we drop a small steel ball (size 3mm diameter; weight 1.10 grams) and a paper (size 11.7 inches length and 8.3 inches breadth; weight 4.5 grams) from a height. The steel ball will win the race to the ground due to its aerodynamic structure.Now imagine the same steel ball with the same weight converted to the structure similar that of paper. What will be the result? Which object will fall first; steel sheet or paper?

- In okorder /... 11.7x8.3 inch paper 97.11 square inches 0.062651488 sq meters at 4.5gm is a non-standard 19 pound bond ledger paper, but that is OK, because at least it is in range. 38 gauge steel sheets are about the thinnest that hold their structure 0.00625 thick 1221 g/m? or, at 11.7x8.3 76.5grams So, with this data at hand we can better visualize the situation. Paper of 0.00625 thick in the size shown is 35# paper 131.68 g/m? 8.25grams Steel is higher in density than paper, so you cannot get the same size and air flow without it being lighter in weight than the steel and the air resistance would be lower for the heavier item, so steel of the same shape and thickness as paper falls faster. Suppose you want paper heavier than steel for the same area, then the thickness increases. Will a steel sheet 0.00625 thick and 11.7x8.3 inch size 76.5gm fall faster or slower than a 9 or 10 times thicker paper sheet? If it was able to hold flat in each type the thicker paper should get more backflow behind it aerodynamically and fall faster than an equal weight thinner steel sheet as my guess, but I don't have those numbers. The steel will always be heavier than the paper for the same exact shape and thickness by about 9x. My answer here is difficult, but the question has some flaws to think about.

Send your message to us

Prepainted Galvanized Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords