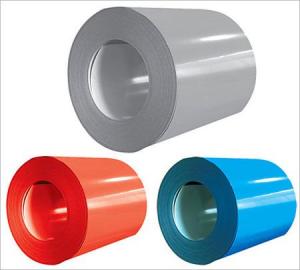

Prepainted Galvanized Steel Coils-Blue

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50mt m.t.

- Supply Capability:

- 5000 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Prepainted Galvanized Steel Coils-Blue

With galvanized steel as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

Brand Name: HBSTEEL

Specifications Of Hot Sell Prepainted Galvanized Steel

|

Thickness 0.23-1.2mm (BMT) |

|

Zinc Coating 80-275g/m2 |

|

Color According to RAL color fan |

|

Internal Diameter 508mm or 610mm |

|

Coil Weight 4-8MT |

|

Quality Commercial and structural quality |

|

Paint Polyester paint for topside, epoxy for reverse |

|

Standard JIS G 3312, ASTM A755M, EN 10169 |

|

Base Steel Grade SGCC,SGCD,DX51D+Z,DX52D+Z;S200GD,S220GD, S280GD,S350GD,CS,FS,SS |

Chemical Composition Of Prepainted Galvanized Steel

|

C |

Si |

Mn |

P |

|

0.04-0.06% |

0.01-0.03% |

0.18-0.22% |

0.014-0.016% |

Technical Data Of Prepainted Galvanized Steel

|

Yield Strength |

(Mpa) 280-320 |

|

Tensile Strength |

(Mpa) 340-390 |

|

Elongation |

20%-30% |

|

Reverse Impact |

9J |

|

T-bending |

≥2T |

|

Pencil Hardness |

≥2H |

|

Duration Of Salt Spray Test |

500 H |

|

Bending At 180 Degree |

No crack, purling and fraction |

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making steel roofing,insulation panel, corrugate sheet, facade wall,shutters,T-bar and home appliance.

Packaging & Delivery Of Hot Sell Prepainted Galvanized Steel

The packing of coils consists of anti-damp paper, PVC film, hardboard paper, steel box, strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye to the side) or wooden pallets(eye to the sky).

Production Flow Of Hot Sell Prepainted Galvanized Steel

Production flow of hot sell prepainted galvanized steel include dual uncoiler,stitcher, bridles, entry accumulater, degreasing & chemical section, prime coater, prime oven, prime water quench, finish coating, finish back coater, finish oven, finish water quench, exit accumulater and recoiler.

- Q: in a lab at school we did heat treatment of steelwhat are the possible phases present in the steel sample in as-received, as-quenched and as-tempered conditions? specifically when is it ferrite, austenite and pearliteis the steel originally in the ferrite phase? then when headed turns into austenite and when quenched martensite is formed and when tempered cermentite is formed...........where is pearlite involved and am i correct about the ferrite?

- hey from what i learned in uni last sem, steel is originally ferrite form at first at room conditions. it will undergo poly morphic transformation to become FCC structure austenite form at 912 degree celcius. under conditions, it can become pearlite (which is a combination of ferrite and cementite) or bainitie( a finer form of pearlite). queching conditions to room temperature will form martensite which is the strongest but brittle steel form. tempered cementite is formed when we quench it and then raise temperatures before sir cooling. hope it helps, pls vote me best answer is i deserve it. thanks

- Q: How are steel coils welded together?

- Steel coils are typically welded together using one of two methods: either by resistance welding or by arc welding. In resistance welding, the coils are pressed together and an electric current is passed through them, generating heat and causing the coils to fuse together. Arc welding, on the other hand, involves the use of an electric arc that melts the edges of the coils, creating a molten pool. As the pool solidifies, the coils bond together, forming a strong weld. Both methods ensure a secure and durable connection between the steel coils.

- Q: How are steel coils protected from chemical damage?

- Steel coils are protected from chemical damage through various methods such as applying protective coatings, using corrosion inhibitors, and storing them in controlled environments to minimize exposure to harmful chemicals.

- Q: I need to know how you rate the hardness of steel any ideas?

- For the backyarder to rate hardness, you do a file test. If a smooth file will not mark the steel, it's around 60+RC (Rockwell C scale). If it will mark it with difficulty, the hardness is probably around 56- 58RC. If it will file easily, it's mild steel or is in annealed form, if it is a hardenable steel.

- Q: i currently have just steel guitar strings, not a fan they need replacing and i was wondering whats the difference between steel and bronze strings and or nickle strings?

- This Site Might Help You. RE: steel vs bronze acoustic guitar strings? i currently have just steel guitar strings, not a fan they need replacing and i was wondering whats the difference between steel and bronze strings and or nickle strings?

- Q: What is the process for uncoiling and recoiling steel coils?

- The process for uncoiling and recoiling steel coils involves several steps to ensure the safe and efficient handling of the coils. 1. Unloading: The steel coils are typically transported to the desired location using cranes or forklifts. They are carefully unloaded from the transportation vehicle and placed in a designated area. 2. Inspection: Before uncoiling, it is crucial to inspect the steel coils for any damage or defects. This step ensures that only quality coils are processed further. 3. Securing: Once inspected, the steel coils are secured to prevent any movement during the uncoiling process. This is done by using clamps or straps to hold the coils firmly in place. 4. Uncoiling: Uncoiling involves the gradual unwinding of the steel coil. This can be done manually or using specialized machinery such as uncoilers or decoilers. The coil is typically fed through a series of rollers that help guide the unwinding process. 5. Straightening: In some cases, the steel coil may need to be straightened before further processing. This can be done using straightening machines that apply pressure to remove any bends or twists in the steel. 6. Cutting: If required, the uncoiled steel coil may be cut into smaller sections or sheets. This can be done using shearing machines or other cutting tools. The dimensions and size of the cuts depend on the specific requirements of the project. 7. Recoiling: Once the desired processing steps are completed, the steel coil can be recoiled. This involves rewinding the steel into a new coil shape. Recoiling can be done manually or using recoilers, which wind the steel evenly and tightly to maintain its integrity. 8. Packaging and storage: After recoiling, the steel coils are typically packaged and stored for further transportation or use. They may be wrapped in protective materials such as plastic or metal sheets to prevent corrosion or damage. Overall, the process for uncoiling and recoiling steel coils requires careful handling, inspection, and the use of specialized machinery. By following these steps, steel coils can be efficiently processed and prepared for various applications in industries such as construction, automotive, and manufacturing.

- Q: Can steel coils be coated with electrically conductive materials?

- Yes, steel coils can be coated with electrically conductive materials.

- Q: The Iron and Steel Corporation of Great Britain (1949) or Iron and Steel Bill was introduced in 1949 during the Labour post-war Government.What was it introduced for?

- Iron and Steel Bill That would be the Bill to nationalise the Steel industry in UK so that the Socialist Government could destroy it. Britain having won the War against Hitler promptly elected a nasty little Fascist who called himself a socialist Clement Atlee who went and nationalised many key Industries in UK so that the Government could run them. In 1979 British Steel was costing the UK tax payer a ?Million per day to keep running and was on the point of collapse with Steel production declining. Unfortunately it wasn't until Mrs. Thatcher came to power in 1979 that they were later put back into the Public sector and shares in British Steel could be bought by the Public and the Company run by people who knew how to run a steel industry. As a consequence Britain now produces more steel than it has ever done in its History.

- Q: How do steel coils contribute to earthquake resistance in structures?

- Steel coils contribute to earthquake resistance in structures by providing strength and flexibility. When used in the construction of buildings, steel coils can absorb and dissipate the energy generated by an earthquake, preventing it from causing significant damage. The high tensile strength of steel allows it to withstand the lateral forces and vibrations during an earthquake, ensuring the structural integrity of the building. Additionally, the ductility of steel allows it to bend and deform without breaking, further enhancing its ability to withstand seismic activity.

- Q: A steel rod AISI 1040 has the ultimate tensile strength Sut of 113 kpsi. Determine the rotating bending specimen's endurance limit S'e at 10 to the 6th cycles.

- Endurance Limit Of Steel

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2008 |

| Annual Output Value | |

| Main Markets | Asia |

| Company Certifications | ISO9001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin Port |

| Export Percentage | 50% |

| No.of Employees in Trade Department | 50 |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | Over 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered |

| Product Price Range | Average |

Send your message to us

Prepainted Galvanized Steel Coils-Blue

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50mt m.t.

- Supply Capability:

- 5000 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords