Thickness: 0.15 - 2.0 mm

Technique: Hot Rolled

Application: Container Plate

Surface Treatment: Galvanized

Secondary Or Not: Non-secondary

Certification: CE

Special Pipe: Thick Wall Pipe

Alloy Or Not: Non-alloy

Section Shape: Other

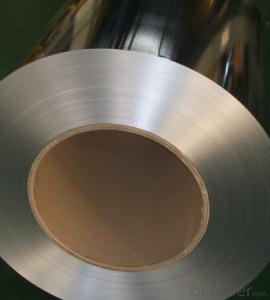

Galvanized Steel Coil Hot Dipped regular spangle CNBM

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

1.Quick Details:

2.Packaging & Delivery

| Packaging Details: | standard package |

|---|---|

| Delivery Detail: | 1-4 week |

cold rolled galvanizing steel coil

galvanized iron steel coil

| Product name | hot rolling galvanized steel coil |

| Raw material | SGCC, SPCC, DC51D, SGHC,A653 |

| Certificate | ISO9001,BV,SGS |

| Thickness | 0.13mm-2.0mm |

| Width | 1250mm or under |

| Tolerance | thickness+/-0.01mm |

| Surface treatment | galvanized steel sheets |

T Bending (top-coating) T Bending (back-coating) | ≤3T ≤4T |

| Anti-MEK Wiping | ≥100times |

| Zinc coating | 40-180g |

| Type of coating structure | 2/1 or 2/2 coating, or customized |

| Standard | GB/T12754-2006, GB/T9761-1988, GB/T9754-1988, GB/T6739-1996, HG/T3830-2006, HG/T3830-2006, GB/T1732-93, GB/T9286-1998, GB/T1771-1991, GB/T14522-93 |

| Color | Silver |

| Application | construction material for building industry ,structural use, roofing, commercial use ,household appliance,industry facilities,office buildings |

5.What is the application of Steel Coil?

There are two sides,one is out side: Workshop, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth;the other is inside: Door, doorcase, light steel roof structure, folding screen, elevator, stairway, vent gutter.

- Q: benchmade mpr with m390 steel knife. Is it better than d2 s30v or 154cm steel?

- From what I understand m390 is a new steel (at least for benchmade) so there doesn't seem to be a consensus on how it performs. Looking at the table, it should be very corrosion resistant. I'd guess it could be classified as a stainless steel. Sorry I don't have more info for you. EDIT: here's a link from the steel manufacturer. I hope this info helps.

- Q: basically a builder told us steel is good but when we got MFI, BQ they only have acrylic

- I okorder . There are so many articles on this site that talk about all of the bathtubs available today. If you're wondering about what kind of material is best for a bathtub, this site will definitely help!

- Q: So what's harder gold or steel

- Steel Gold is a soft metal, that's why people bite it to make sure it is real.

- Q: I am doing a project on how revolvers work and what materials they use and would like to know what specific grade of stainless steel they use for the manufacturing of the frame and cylinder?

- *Rifle barrels are usually made from steel alloys called ordinance steel, nickel steel, chrome-molybdenum steel, or stainless steel, depending upon the requirements of the cartridge for which they are chambered. The higher the pressure and velocity of a cartridge (pressure and velocity usually go up together), the faster it will wear out a barrel. To give a satisfactory service life, barrels for high velocity cartridges must me made from tougher and harder steel than barrels for lower pressure cartridges. *The 400 (416) series SS commonly known as ordnance grade , is what barrels are made from . *If you want your barrel to be made from super alloy then it is 718 Inconel ,but a costly affair.

- Q: What are the different methods of welding steel coils?

- There are several methods of welding steel coils, including MIG (Metal Inert Gas) welding, TIG (Tungsten Inert Gas) welding, and resistance welding. MIG welding uses a consumable electrode wire and an inert gas as a shielding medium to create an arc and join the coils. TIG welding, on the other hand, uses a non-consumable tungsten electrode and a separate filler material to create the weld. Resistance welding involves applying pressure and passing an electric current through the coils to create a weld. Each method has its advantages and is chosen based on factors such as the type and thickness of the steel, desired quality, and production requirements.

- Q: I have a knife with AUS8 Stainless Steel. No idea what that means. I want to know some of the best stainless steels for knifes and all you can tell me about stainless steel would be great. I was browsing google and looking at grades and had no idea what all the numbers meant. Thanks!

- I do engraving on knife blades (actually all kinds of metal but occasionally knife blades). Every company's blades are a little different. I get the idea that different companies have different compounds. All the materials are some compromise between hardness, toughness, corrosion resistance, machineability and other considerations. Stainless is generally not as good as a high-carbon steel, but high-carbon steel rusts and turns black. Stainless is much easier to keep clean.

- Q: They both sell the same thingIf prices are to high companies won't by the steelIf prices are to low then the steel company won't earn enoughWhy are some steel companies more successful than others

- Steel is a global commodity. There is some variety in product (flat rolled, tubing, etc), but basically the same product worldwide. Cost to the customer includes shipping of a very heavy product. Inputs are also heavy and costly to ship. Inputs: - Coal - Iron Ore. Some firms have the ability to recycle old steel, a competitive advantage. - Energy (very energy intensive industry) - Labor - Machinery. A new blast furnace is more efficient than 50 years old. So the most profitable steel firms have some of these characteristics: - Proximity to raw materials - Proximity to customers - Access to cheaper means of transportation; rail and sea - Newer machinery - Cheaper labor force - Reasonable cost for electricity and fuel for furnaces

- Q: What is the role of steel coils in the production of appliances?

- Steel coils play a crucial role in the production of appliances as they serve as the primary material for constructing the outer bodies, frames, and internal components of various appliances. The coils are formed into desired shapes and sizes, ensuring durability, stability, and strength of the appliances. Additionally, the steel coils enable efficient heat transfer, enhancing the performance and longevity of appliances such as refrigerators, stoves, and washing machines.

- Q: What really is the difference between stain-less steel and iron? I only know that iron is an element, and stain-less steel is an alloy...but what else is there?

- Steel is an alloy composed of mainly iron and carbon. Pure iron is very rarely used anymore. Depend on the concentration of the carbon, you can get from wrought iron to high grade steel. For stainless steel, Chromium is added to the alloy to prevent rusting. Just go to wiki. you should be able to find a lot more about it

- Q: How are steel coils used in the manufacturing of suspension systems?

- Steel coils are used in the manufacturing of suspension systems as they provide the necessary support and cushioning for vehicles. These coils, also known as coil springs, are placed between the vehicle's chassis and the wheels to absorb impact and ensure a smooth ride. The steel coils are designed to compress and expand under the weight and movement of the vehicle, effectively absorbing shocks, vibrations, and uneven road surfaces. This helps to improve stability, handling, and overall comfort for the driver and passengers.

Send your message to us

Galvanized Steel Coil Hot Dipped regular spangle CNBM

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords