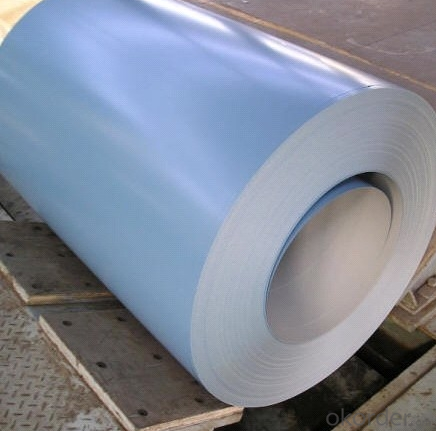

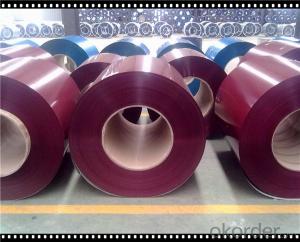

PrepaintedHot-Dip and Galvanized Steel Coil CNBM

- Ref Price:

-

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 3000 m.t./month

Add to My Favorites

Follow us:

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Quick Details

| Standard: | AISI, ASTM, GB, JIS | Grade: | Q195/235/345,ASTM A36,SS400,SPHC | Thickness: | 1.5-25mm |

| Technique: | Hot Rolled | Application: | Container Plate | Special Use: | High-strength Steel Plate |

| Width: | 300-1500mm | Length: | coil | Surface Treatment: | black/bright/galvanized,etc |

| Authentication: | ISO9001-2008,SGS.BV,etc |

|

|

|

|

Packaging & Delivery

| Packaging Details: | tandard seaworthy export package or as customers required |

| Delivery Detail: | within 25 days after confirming the order |

Sepcification and Feature

| Minerals & metallurgy |

Thickness | 1.8-20mm |

Width | 914-2000mm |

Coil weight | about 25 tons |

Material Grade | A36,Q195,Q235,SS400,SPHC,ST37/52 |

Technique | hot rolled |

Standard | AISI,ASTM,DIN,GB,JIS |

|

|

What is the application of Steel Coil?

There are two sides,one is out side: Workshop, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth;the other is inside: Door, doorcase, light steel roof structure, folding screen, elevator, stairway, vent gutter.

- Q: Can you reload spent casings if they are steel?

- Steel Casings

- Q: How are steel coils priced in the market?

- Steel coils are typically priced in the market based on various factors such as the current supply and demand dynamics, global steel prices, production costs, and market competition. Additionally, specific attributes of the steel coils, such as size, thickness, grade, and coating, can also influence the pricing. Overall, it is a complex process that involves analyzing multiple factors to determine the appropriate price for steel coils in the market.

- Q: I need to identify a metal. It is rusty so I suspect it is either iron or steel. Since they both have similar densities and are magnetic, how do I tell the difference betweeen steel and iron?

- Iron is a natural ore. Google: Iron ore, click on Mineral Information Institute - Iron Ore. Steel is a man-made material, consisting of iron. Google: Sir Henry Bessemer, inventor.

- Q: What are the different types of corrosion protection methods used for steel coils?

- There are several types of corrosion protection methods used for steel coils, including:

1. Coating: Applying a protective layer of paint or coating, such as epoxy or zinc, on the surface of the steel coil to prevent direct contact with moisture and corrosive substances.

2. Galvanization: Immersing the steel coil in a bath of molten zinc to create a protective zinc coating, which acts as a sacrificial layer that corrodes first before the steel.

3. VCI (Volatile Corrosion Inhibitors): Using volatile chemicals that release protective vapors, which form a thin layer on the steel coil's surface, inhibiting corrosion by blocking moisture and oxygen.

4. Passivation: Treating the steel coil with chemicals like nitric acid to remove impurities, creating a passive oxide layer that protects against corrosion.

5. Cathodic Protection: Connecting the steel coil to a sacrificial anode (usually made of zinc or magnesium) or using impressed current to provide a flow of electrons, which prevents corrosion by making the steel coil the cathode in an electrochemical cell.

6. Environmental Control: Maintaining controlled temperature, humidity, and atmospheric conditions during storage and transportation to minimize exposure to corrosive elements.

These methods can be used individually or in combination, depending on the specific requirements and environmental conditions.

- Q: What are the different methods of annealing steel coils?

- There are several different methods of annealing steel coils, each with its own advantages and applications. The main methods include full annealing, process annealing, and spheroidize annealing.

Full annealing is the most common method and involves heating the steel coils to a temperature above its critical point, typically between 800 and 900 degrees Celsius (1472 and 1652 degrees Fahrenheit), and then slowly cooling it down in a controlled manner. This process helps to refine the grain structure of the steel, making it softer and more ductile. Full annealing is often used to relieve internal stresses, improve machinability, and enhance the overall mechanical properties of the steel.

Process annealing, also known as subcritical annealing or stress relief annealing, is a method used to reduce the hardness and brittleness of steel coils. It involves heating the coils to a temperature below its critical point, typically between 550 and 650 degrees Celsius (1022 and 1202 degrees Fahrenheit), and then slowly cooling them down. This process helps to relieve internal stresses that may have developed during previous manufacturing processes, such as cold working or welding. Process annealing is commonly used to improve the formability and toughness of steel coils.

Spheroidize annealing is a specific type of annealing that is used to soften high carbon and alloy steels. It involves heating the steel coils to a temperature slightly below its critical point, typically between 650 and 700 degrees Celsius (1202 and 1292 degrees Fahrenheit), and then holding it at that temperature for a prolonged period of time. This allows the carbides within the steel to transform into rounded or spheroidal shapes, which increases the steel's machinability and ductility. Spheroidize annealing is often employed in the production of cutting tools, bearings, and other applications where improved machinability is desired.

In addition to these main methods, there are also variations and specialized techniques that can be used for specific purposes, such as recrystallization annealing, intercritical annealing, and solution annealing. Each method has its own set of parameters and temperature ranges, and the choice of annealing method depends on factors such as the type of steel, desired mechanical properties, and the intended application of the steel coils.

- Q: What are the dimensions of steel coils used in the automotive industry?

- The dimensions of steel coils used in the automotive industry can vary depending on the specific application, but common dimensions range from 0.5mm to 3mm in thickness and 600mm to 2000mm in width.

- Q: could anybody tell me the the weight of a cubic metre of mild steel? and where to get this info from?

- i thnk 7.85 the density of ms is 7.85 kg/cm2 and formula is density=mass/volume u have volume=1m3 7.85*1=mass so 7.85 kg

- Q: How are steel coils used in the production of pressure vessels?

- Steel coils are used in the production of pressure vessels as they provide a strong and durable material for constructing the vessel's shell. The coils are typically formed and welded to create the cylindrical shape of the vessel, ensuring it can withstand high pressure and contain fluids or gases safely.

- Q: Is cold steel actually steel? Does it hurt? Why is it used in training? First one to goodly answer those questions gets 10 points.

- Fluffy blue handcuffs.

- Q: What is the role of steel coils in the electrical industry?

- The electrical industry greatly relies on steel coils due to their versatile applications and significant contributions. Transformers, which play a crucial role in power distribution and voltage regulation, utilize steel coils as essential components. These coils facilitate the transfer of electrical energy between circuits, enabling efficient transmission over long distances.

Moreover, electric motors and generators heavily rely on steel coils. These coils are wound around the stator and rotor, creating magnetic fields that facilitate the conversion of electrical energy into mechanical energy and vice versa. This conversion process holds immense importance in industries such as automotive, manufacturing, and renewable energy.

Steel coils also serve a vital purpose in the production of electrical cables and wiring. They provide strength, durability, and protection to the conductive copper or aluminum wires within the cables, ensuring their structural integrity. This, in turn, guarantees safe and efficient electricity transmission.

Additionally, steel coils find application in electrical equipment like solenoids and relays. Their presence enables the creation of magnetic fields that control the flow of electrical current. Furthermore, various electrical appliances, including refrigerators, air conditioners, and televisions, rely on steel coils as crucial components for their proper functioning.

In conclusion, the role of steel coils in the electrical industry cannot be overstated. From transformers to motors, generators, cables, and electrical equipment, these coils contribute significantly to the efficient distribution, conversion, and transmission of electrical energy.