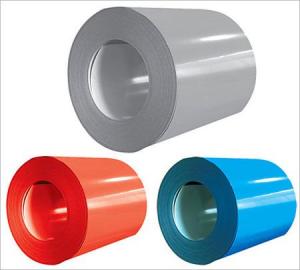

Hot rolled carbon steel galvanized steel coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Standard:AISI, ASTM, BS, DIN, GB, JIS

Grade:Carbon/Alloy/Stainless steel

Thickness:0.3-100mm

Place of Origin:Shanghai, China (Mainland)

Model Number:Steel Coil

Type:Coil & Plate

Technique:hot & cold rolled

Surface Treatment:Coated & Galvanized

Application:Ship Plate

Special Use:High-strength Steel Plate

Width:1000-2000

Length:coils

Product Name:Hot rolled carbon steel galvanized steel coil

Product type:galvanized steel coil

Service:OEM/ODM

Sample:available

Certificate:ISO,BV .

Packaging & Delivery

| Packaging Details: | galvanized steel coil packing: Bundles, seaworthy wooden cases.With or without edge protector, steel hoop and seals, or as per customers' requirements |

|---|---|

| Delivery Detail: | 7-15 days |

Specifications

Hot rolled carbon steel galvanized steel coil

* Hot & Cold rolled

* Carbon/Alloy/Stainless steel

* thickness: 0.3-100mm

Hot rolled carbon steel galvanized steel coil

Type | Hot rolled carbon steel galvanized steel coil |

thinckness | 0.3-6mm/3-14mm |

Widthness | 1000mm-2000mm |

Brand name | TISCO,LISCO,Baosteel ,etc |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Material | 201,202, 301,302,303,304,304L,309,310,316,321,410,410S,420,420J1,430,304F,316L, 316F,316Ti,310s,314,314l,317,317l,302HQ. 410,430,430F,416,431,420JS.etc. Q235B, Q345B, SS400,SS490,S235JR,S345JR |

Application range | Foodstuff, Gas, metallurgy, biology, electron, chemical, petroleum, boiler, nuclear energy, Medical equipment, fertilizer etc |

surface | 2B,No.1 |

Package | Standard export sea-worthy packing |

Delivery time | 10-15 days after got deposit |

- Q: 7850kg/cu.m density is typical for all type of steel? like reibar, I- beam and so on

- 90% of the steels used today are plain mild carbon steels consisting of iron with less than 1% carbon content and as such have a density of about 7750 kg/cubic meter. Some special steels which have a significant percentage of alloying elements such as chrome or manganese or other elements will have greater density bringing the steel up to about 8000 kg / cubic meter. There are a greater many factors influencing the exact density of a steel. Even for steels of exactly the same content of iron , carbon and other alloying elements, there may be a difference ( very small mind you ) in density due to work hardening. The difference in this case is due to movement of dislocations which become locked in the grain boundaries and this forms a more dense crystal structure. For this same reason, the theoretical density of steel (which does not take into account dislocations) is greater than the measured density of steel.

- Q: What are the challenges in coil blanking?

- In order to achieve efficient and accurate production, coil blanking, a process used to cut flat metal sheets from coiled stock, must tackle several challenges. Some of the key challenges include: 1. Material variations: Coiled stock can have variations in thickness, width, and surface quality, which can impact the cutting process and result in inconsistent blanks. To ensure consistent quality and dimensional accuracy, it is crucial to carefully select and control the material. 2. Coil set and crossbow: Coiled stock often has inherent shape imperfections like coil set (longitudinal curvature) and crossbow (transverse curvature), which can cause alignment issues during cutting. Minimizing these imperfections requires the use of specialized equipment and techniques, such as straighteners and leveling systems. 3. Coil edge condition: The edges of coiled stock can have burrs, waves, or irregularities, which can affect the quality and precision of the cut blanks. Employing proper edge conditioning techniques, like deburring or edge trimming, is necessary to ensure clean and straight edges. 4. Slitting and shearing forces: The forces exerted during coil blanking can induce stresses and strains in the material, potentially leading to deformation or springback. To minimize these effects and maintain dimensional accuracy, careful consideration of slitting and shearing forces, along with proper tooling design and machine settings, is necessary. 5. Scrap and material waste: Coil blanking can generate significant amounts of scrap material, especially during setup and adjustment phases. Managing scrap and reducing material waste is crucial to optimize production efficiency and minimize costs. Efficient nesting algorithms and real-time monitoring systems can help achieve this. 6. Automation and productivity: Due to market demands, coil blanking often requires high-speed and high-volume production. Enhancing productivity can be achieved through the implementation of automation systems, such as robotic material handling and advanced control systems. However, integrating and synchronizing these components with the cutting process requires careful planning and system integration expertise. Overall, addressing these challenges in coil blanking necessitates proper material selection, advanced equipment, specialized techniques, and efficient process control. By overcoming these challenges, manufacturers can achieve consistent quality, dimensional accuracy, and productivity in coil blanking operations.

- Q: I want to anodize steel using heat. some steel turns gray instead of coloring when I heat it up using a torch.

- Steel doesn't anodize in the sense that aluminum and some other metals do. However, it can be heat-colored. The trick is to clean the surface first (it must be oxide free), then heat gently until the colors appear. These are called temper colors in steel. They are due to a thin adherent layer of oxide that forms and thickens as temperature is increased. They are quite temperature dependent. As the steel is heated, the first color to appear is pale yellow. This will progress through darker yellows, browns, purples, and blues as the temperature rises. Above blue, the oxide becomes the gray/black color you are apparently getting - this is the result of heating too fast and too hot. See the chart at the site below for colors in plain carbon steel. Note that the temperatures are pretty low - It all starts around 400 F and if you go above 600 F the show's all over.

- Q: What are the main factors to consider when selecting a steel coil supplier?

- When selecting a steel coil supplier, the main factors to consider include the supplier's reputation and reliability, the quality of their products, their pricing and payment terms, their delivery options and lead times, their customer service and support, as well as their ability to meet your specific requirements and specifications.

- Q: What are the challenges in coil blanking for high-strength steel?

- Coil blanking for high-strength steel presents several hurdles due to the unique properties of this material. One of the main obstacles lies in the steel's high tensile strength, which makes cutting and blanking more difficult when compared to traditional steel grades. High-strength steel is typically harder and less malleable, resulting in heightened tool wear and greater cutting forces. Therefore, specialized cutting tools capable of enduring these extreme conditions are necessary. Additionally, the augmented cutting forces can cause increased vibrations, potentially impacting the accuracy and quality of the blanks. Another challenge arises from the spring-back effect displayed by high-strength steel after it is cut. This means that the material tends to return to its original shape, creating difficulties in achieving precise dimensions and tolerances in the blanks. Consequently, careful consideration and adjustment of the cutting parameters are required to minimize the spring-back effect. Furthermore, high-strength steel often contains a higher carbon content, leading to increased work hardening during the blanking process. As a result, the material becomes even harder and more brittle, making it more susceptible to cracks and fractures. To overcome this challenge, proper lubrication and cooling techniques are crucial in reducing heat buildup and minimizing the risk of cracking. Additionally, the heightened strength of the steel can also impact overall production efficiency. The increased cutting forces and tool wear may necessitate a reduction in cutting speeds, resulting in longer processing times. This can affect the productivity and throughput of the coil blanking process, requiring meticulous optimization and planning. In conclusion, the challenges involved in coil blanking for high-strength steel encompass increased cutting forces, tool wear, the spring-back effect, work hardening, and reduced production efficiency. Overcoming these challenges necessitates the use of specialized cutting tools, precise cutting parameters, proper lubrication and cooling techniques, and meticulous optimization of the production process.

- Q: where can i get a thick sheet of steel ? and is steel bullet proff for example if you shoot a bullet on steel will that bullet bounce right off the steel ?

- Try the business-to-business yellow pages in your area. A local hardware store can also tell you who to contact. Or search steel plate or sheet metal on the internet to find a local supplier. No, sheet steel is not bullet proof, unless you get heavy plate. Depending on how thick it is, the plate will deform if hit by a high velocity bullet, but usually not enough to matter. Bullets have velocities from about 500 ft/sec up to roughly 3000 ft/sec, depending on the type of weapon used. I wouldn't try to use anything thinner than 3/4 inch. You'll have to experiment and see what it will actually stop. I can't guarantee it'll stop a high-velocity rifle slug. Try it and see.

- Q: What are the advantages of using pre-painted steel coils?

- There are several advantages of using pre-painted steel coils. Firstly, they offer a wide range of color options, allowing for greater design flexibility and customization. Secondly, pre-painted steel coils have a protective coating that enhances their durability and resistance to corrosion, extending their lifespan. Additionally, pre-painted steel coils are available in various finishes, such as matte, glossy, or textured, providing aesthetic appeal. Furthermore, these coils are ready for immediate use, saving time and labor costs associated with painting on-site. Overall, pre-painted steel coils offer convenience, durability, versatility, and enhanced aesthetics, making them a preferred choice in various industries.

- Q: What are the main raw materials used in making steel coils?

- The main raw materials used in making steel coils are iron ore, coal, and limestone.

- Q: The Chinese invented the windmill long before the 1800's, but I cannot find anywhere who invented the steel windmill, I believe it was in the 1800'sIf you know the answer that'd be great!And also if you could find the date it was patented? Thanks SO much!

- The Steel Eclipse Type WG was the first of several self-oiling steel windmills marketed by Fairbanks, Morse, and Company after they became the distributor of all the Eclipse mills about the start of the 20th Century. It has the more important distinction of having been the only widely distributed worm-gear mill in the history of American windmill manufacture. Produced from about 1926 to the mid-1930's, the Steel Eclipse remains in the field today in considerable number in most parts of the country. Hope this helps!

- Q: What are the guidelines for handling damaged steel coils?

- The guidelines for handling damaged steel coils typically involve assessing the extent of the damage, ensuring proper safety precautions are in place, and following industry best practices for handling and storing damaged coils. It is important to inspect the damaged coils for any potential hazards, such as sharp edges or protruding objects, and to use appropriate lifting equipment and protective gear when moving or transporting them. Additionally, damaged coils should be segregated from undamaged ones to prevent further deterioration and potential safety risks.

Send your message to us

Hot rolled carbon steel galvanized steel coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords