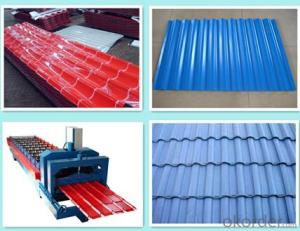

Prepainted galvanized Steel Coil Roofing steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,GB,JIS | Grade: | CGCC, DX51D | Thickness: | 0.25-0.8MM |

| Place of Origin: | Zhejiang China (Mainland) | Brand Name: | CNBM | Type: | Steel Coil |

| Technique: | Cold Rolled | Surface Treatment: | Coated | Application: | Roofing |

| Special Use: | Silicon Steel | Width: | 800-1250MM | Color: | Ral or according to sample |

Packaging & Delivery

| Packaging Detail: | color steel coil STANDARD EXPORT SEAWORTHY PACKING |

| Delivery Detail: | 25 DAYS AFTER DOWN PAYMENT |

Specifications

color steel coil

Prime Quality, Quick Delivery, Competitive Price

Prepainted Galvanized Steel Coil (PPGI/PPGL)

Base material: Hot dipped galvanized steel

Width: available from 800MM to 1250MM

Width Tolerance: within 0.02MM

Thickness: available from 0.18MM to 0.80MM

Thickness Tolerance: within 0.15MM

Performance: Smooth or Matte

Color: according to RAL standard

Lacquer Coating thickness: according to customer needs

Supply capacity: 8,000 Metric Ton per month

Our products has good performance on combining force and anti-erosion. We offer fine quality products and best price for our international customers.

COLOR COATING LINE

A Dual Uncoiler

B Stitcher

C Bridles

D Entry Accumulater

E Degreasing & Chemical Section

F Prime Coater

G Prime Oven

H Prime Water Quench

I Finish Coating

J Finish Back Coater

K Finish Oven

L Finish Water Quench

M Exit Accumulater

N Recoiler

- Q: So, i recently bought the game red steel 2 and i beat it, it was an amazing game! although since i had never played the first one ( i never knew about it actually) i had alot of questions like, why was he banished, where is his actual master, etc so i searched up on Youtube, red steel 1 to figure it all out and the games look nothing alike!! i mean the first one is like nothing but guns and the characters arnt the same ( well at least i dont think so) could someone explain why?

- Red Steel 2 isn't really a sequel to Red Steel 1 in a normal sense. The reason the new one is named Red Steel 2 is because of the Sword + Gun combat, which was also in the first game (even though the sword part wasn't good in the first one). Other than that, I'm guessing Ubisoft just wanted to take a different, less realistic approach with it.

- Q: im buying a new guitar,, it has a built in tuner and its semi acoustic (can be plugged into an amplifier) ,, im trying to choose which strings are better ,, steel or nylon..?

- That's not an option Guitars are designed for either nylon or steel strings. They aren't interchangeable. Putting steel strings on a guitar designed for nylon strings WILL destroy the guitar. If you've already picked out the guitar you want, then you've already made your decision about nylon or steel.

- Q: How do steel coils compare to other materials in terms of cost?

- Steel coils are generally more cost-effective compared to other materials due to their durability, versatility, and widespread availability in the market.

- Q: i have searched high and low, but can't find information anywhere!bainitic and pearlitic steels are too in depth, just would like to know if it is hsla steel, or mild steel, or stainless steel etc...thank you in advance :)

- Well i guess they have to ( engineers ) take into account stuff like tensile stress and crap and then also the amount by which it contracts and expands during extremme tempertures if i were you put this question under the engineering section. It might lead to a right on the nail answer and also there ought to be a log book which gives us like you know the best steel for railroad maufacture. Architectural engineers or construction engineers are always goin around with books bookworms to be more precise. haha anyways best of luck mate.

- Q: What is the role of steel coils in the manufacturing of pipes and tubes?

- Steel coils play a crucial role in the manufacturing of pipes and tubes as they serve as the primary raw material. These coils are unwound and then formed into the desired shape through various processes such as rolling, bending, and welding. The strength and durability of steel make it an ideal material for pipes and tubes, ensuring their ability to withstand high pressure, corrosion, and other demanding conditions.

- Q: How do steel coils contribute to the marine vessel construction industry?

- Steel coils are essential components in the marine vessel construction industry as they play a crucial role in the fabrication of various structural elements of ships and boats. These coils are typically made of high-quality steel and are used in a variety of ways to contribute to the construction and performance of marine vessels. Firstly, steel coils are utilized in the construction of the hull, which is the main body of the ship. The hull requires strong and durable materials to withstand the harsh conditions of the sea, including waves, corrosion, and impacts. Steel coils provide the necessary strength and integrity to the hull, ensuring the vessel's structural integrity and safety. Moreover, steel coils are also employed in the fabrication of decks, bulkheads, and other internal structures of marine vessels. These components are crucial for dividing the ship into compartments, providing stability, and supporting various equipment and machinery. Steel coils are known for their excellent tensile strength, which allows them to bear heavy loads and resist deformation, making them ideal for constructing these vital components. Additionally, steel coils are used in the construction of propulsion systems and other mechanical parts of marine vessels. These coils are often shaped and formed into specific components, such as shafts, gears, and propellers, which are critical for the vessel's propulsion and maneuverability. The high strength and durability of steel coils ensure the reliability and efficiency of these mechanical systems, enabling smooth navigation and operation of the vessel. Furthermore, steel coils contribute to the marine vessel construction industry by enhancing the overall safety and longevity of ships and boats. Steel is known for its resistance to corrosion, which is a significant concern in marine environments due to the presence of saltwater. By utilizing steel coils, marine vessels can withstand the corrosive effects of seawater, reducing the need for frequent maintenance and repair. This, in turn, improves the lifespan of the vessel and reduces the risk of accidents or failures at sea. In conclusion, steel coils are indispensable in the marine vessel construction industry. These coils provide the necessary strength, durability, and resistance to corrosion, ensuring the safety, performance, and longevity of ships and boats. From the construction of the hull to the fabrication of internal structures and mechanical components, steel coils play a vital role in every aspect of marine vessel construction.

- Q: How do steel coils contribute to corrosion resistance in products?

- Corrosion resistance in products is achieved through a combination of factors provided by steel coils. Firstly, the coils are typically constructed from stainless steel, which contains a high concentration of chromium. This chromium forms a passive film on the steel's surface, acting as a protective oxide layer that prevents corrosion. Furthermore, this film possesses the ability to self-heal, regenerating itself if damaged or scratched, thereby ensuring continuous corrosion protection. In addition, the steel coils undergo a process known as galvanization, which involves applying a layer of zinc to the steel's surface. This zinc layer functions as a sacrificial anode, corroding preferentially to the steel. This sacrificial corrosion shields the underlying steel, effectively preventing the formation of rust and other types of corrosion. Moreover, steel coils can be coated with various protective materials like epoxy or polyurethane to enhance their corrosion resistance. These coatings act as an additional physical barrier, preventing moisture, chemicals, and other corrosive elements from reaching the steel surface. Lastly, steel coils can be manufactured with specific alloying elements such as nickel or molybdenum, further enhancing their resistance to corrosion. These alloying elements bolster the strength and durability of the steel, enabling it to withstand harsh and corrosive environments more effectively. In summary, steel coils contribute to the corrosion resistance of products by utilizing stainless steel, galvanization, protective coatings, and alloying elements. The implementation of these measures ensures that products retain their structural integrity and appearance over time, even under demanding and corrosive conditions.

- Q: What are the different types of coatings applied to steel coils?

- There are various types of coatings that can be applied to steel coils, each with its own specific purpose and benefits. 1. Galvanized Coating: This is one of the most common types of coatings applied to steel coils. It involves the application of a layer of zinc to the steel surface. Galvanized coatings provide excellent corrosion resistance, making them suitable for outdoor applications where the steel may be exposed to moisture or harsh environmental conditions. 2. Galvalume Coating: Similar to galvanized coating, galvalume coating also involves the application of a layer of zinc to the steel surface. However, it also includes a small amount of aluminum, which enhances the corrosion resistance and provides better heat reflectivity. Galvalume coatings are often used in roofing and cladding applications. 3. Pre-painted Coating: Pre-painted coatings involve the application of a layer of paint or primer to the steel surface. This type of coating allows for customization in terms of color and finish. Pre-painted coatings not only enhance the aesthetics of the steel but also provide additional protection against corrosion and weathering. 4. Organic Coating: Organic coatings are typically applied as a topcoat over a galvanized or galvalume coating. They are made of various resins, such as polyester, epoxy, or polyurethane, which provide additional protection against corrosion, abrasion, and chemicals. Organic coatings are commonly used in applications where both aesthetics and durability are important, such as in the automotive industry. 5. Metallic Coating: Metallic coatings, such as aluminum or zinc, are applied to steel coils using a process called hot-dip coating. These coatings provide excellent corrosion resistance and are commonly used in applications where the steel is exposed to high temperatures or corrosive environments. 6. Chromate Conversion Coating: Chromate conversion coatings are applied to steel coils primarily for their corrosion resistance properties. They are commonly used in electrical applications to protect against galvanic corrosion and improve conductivity. Overall, the type of coating applied to steel coils depends on the specific requirements of the application, including the desired level of corrosion resistance, aesthetics, and environmental factors.

- Q: Can steel coils be cut to length?

- Yes, steel coils can be cut to length.

- Q: What is steel made of and what is its molecular weight? It's for a project in chemistry class so if you have a website link as well, that would be great!

- Steel is an alloy consisting mostly of iron with a little Carbon thrown in. Steel is not a molecule, therefore, it does not have a molecular weight. Steel contains atoms of iron and carbon in a crystal lattice, along with various other alloying elements such as manganese, chromium, vanadium, and tungsten.

Send your message to us

Prepainted galvanized Steel Coil Roofing steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords