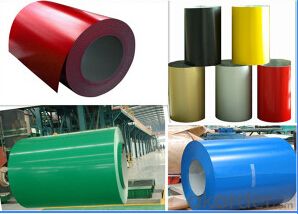

PPGI Prepainted Galvanized Rolled Steel Coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Model NO.:Thickness: 0.125--1.3mm*600-1250mm

Type:Steel Coil

Technique:Hot Rolled

Standard:ASTM, GB, JIS

Surface Treatment:Coated

Special Use:High-strength Steel Plate

Pre-Painted Steel Coi:Width: 610/724/820/914/1000/1200/1219/1220/1250mm

Export Markets:North America, South America, Southeast Asia, Africa, Mid East, Eastern Asia

Additional Info.

Trademark:SGCH

Packing:Standard Packing to Export.

Standard:0.2mm*914mm 0.3mm*1000mm

Origin: China

HS Code:721070100

Production Capacity:8000mt/Month

Product Description

Pre-painted Galvanized Steel Coil

PPGI is made by cold rolled steel sheet and galvanized steel sheets as baseplate,

through the surface pretreatment (degreasing, cleaning, chemical conversion

processing), coated by the method of continuous coatings (roller coating method),

and after roasting and cooling.

SPECIFICATION

1.Standard: AISI, ASTM, BS, DIN, GB, JIS

2.Grade: DX51D+Z, DC51D, SPCC, SGCC, SGHC, CGCC,

3.Surface Treatment Coated: Galvanized, Paint sealant, Coating passivation solution

Substrate Cold rolled, Galvanized sheet

4.Color: RAL Color card

5.Coil ID: 508/610 mm

6.Coil weight: 4-10MT

7.Paint film Front side: 10~25um

Back side: 5~10um

8.Zinc layer: 40~180g per square meter

9.Thickness: 0.125~1.3mm

10.Width: 600~1250mm

11.Length: As requirement

12.Type: Steel plate, Steel Coil, Roofing metal

13.Place of origin: Shandong CHINA(mainland)

14.Deliver time: 20-30 days after receipt of advanced t/t or L/C

Advantages

1. Our company produce various specification and models and national standards of galvanized steel coil

2. Using high-quality material and advanced production technology and equipment for processing

3.Applicable to a humid climate and the harsh corrosive environment

4. Products has been all over the country more than 20 provinces, municipalities and

autonomous regions, and have been exported to Europe, North American, the Middle East,

the South East Asia, Africa, Asia,European and other countries and regions, well received by our buyer.

| commodity | prepained Galvanized Steel Coil (PPGI/ PPGL) |

| Techinical Standard: | JIS G3302-1998, EN10142/10137, ASTM A653 |

| grade | TSGCC, TDX51D / TDX52D / TS250, 280GD |

| Types: | For general / drawing use |

| Thickness | 0.125-1.3mm(0.16-0.8mm is the most advantage thickness)) |

| Width | Width: 610/724/820/914/1000/1200/1219/1220/1250mm |

| Type of coating: | PE, SMP, PVDF |

| Zinc coating | Z40-180g/m2 or AZ40-100g/m2 |

| Top painting: | 5 mic. Primer + 15 mc. R. M. P. |

| Back painting: | 5-10 mic. EP |

| Color: | According to RAL standard |

| ID coil | 508mm / 610mm |

| Coil weight: | 4--8MT |

| Package: | Properly packed for ocean freight exportation in 20' ' containers |

| Application: | Industrial panels, roofing and siding for painting / automobile |

| Price terms | FOB, CFR, CIF |

| Payment terms | 20%TT in advance+80% TT or irrevocable 80%L/C at sight |

| delivery time | 25 days after recepit of 20% TT |

| Remarks | Insurance is all risks |

| MTC 3.1 will be handed on with shipping documents | |

| We accept SGS certificatation test |

- Q: What are the safety precautions when working with steel coils?

- When working with steel coils, it is important to follow several safety precautions. Firstly, workers should always wear the appropriate personal protective equipment (PPE) such as safety glasses, gloves, and steel-toed boots to protect themselves from potential hazards. Additionally, it is crucial to ensure that the work area is clean and free from any debris or obstacles that may cause accidents or tripping. Proper manual lifting techniques should be employed to avoid strain or injury when handling heavy steel coils. Workers should also be trained in the proper use of equipment such as cranes or forklifts to safely transport and store the coils. Regular inspections of equipment and proper maintenance should be conducted to prevent any malfunctions or accidents. Lastly, employees should be aware of emergency procedures and have access to fire extinguishers and first aid kits in case of any unexpected incidents. Overall, prioritizing safety measures and being vigilant can greatly minimize the risks associated with working with steel coils.

- Q: I'm looking for the weight of different types of steel and haven't found anything helpful!!thank you

- Category Material Density Metal Steel, tool 7.715 Metal Wrought Iron 7.75 Metal Carbon Tool Steel 7.82 Metal Steel, cold-drawn 7.83 Metal Carbon Steel 7.84 Metal Steel, C1020, HR 7.85 Metal Pure Iron 7.86 Metal Soft Steel (0.06% C) 7.87 Metal Stainless Steel, 304 8.03 Metal Stainless 18Cr-8Ni 8.03 I looked up specific gravity mild steel. This might get you pointed in the right direction.

- Q: How are steel coils used in the manufacturing of automotive chassis?

- Steel coils are used in the manufacturing of automotive chassis as they are shaped and formed into various structural components such as frame rails, cross members, and support beams. These coils are cut, bent, and welded together to create a strong and rigid chassis structure, providing the necessary strength and stability for the vehicle.

- Q: Hi! does anyone know where can i find a building with a structure of steel frames, i need to do an analysis for school so i need joint details, girder details and such! PLEASE help me! thanks

- if u need to analyse a steel framed structure for joint details the best example would be of a mechanic workshop...the truss of such a workshop is always supported on a portal frame and in most of the case thats a steel structure...do keenly observe the joints at the footing plates that is connected to the girder section...nd also observe the joints in truss of such a frame....myslf m a civil engg. student.

- Q: What are the applications of steel coils in the aerospace industry?

- Steel coils have various applications in the aerospace industry, primarily in the manufacturing of aircraft components. These coils are used to produce structural parts, such as frames, wings, and landing gear, due to their high strength and durability. Additionally, steel coils are utilized in the fabrication of engine components, including turbine blades and exhaust systems, as they can withstand extreme temperatures and pressures. Overall, steel coils play a crucial role in ensuring the safety and performance of aircraft in the aerospace industry.

- Q: How are steel coils used in the manufacturing of electrical equipment?

- Steel coils are commonly used in the manufacturing of electrical equipment as they serve as a key component in transformers and motors. These coils are typically made of high-quality steel and are tightly wound to create an electromagnetic field when an electric current passes through them. This allows for efficient power transmission, voltage regulation, and electromagnetic induction, which are essential functions in various electrical devices.

- Q: I want to know what to my wash stainless fridge door with before applying the stainless steel polish.

- I just use a regular spray on kitchen cleaner like 409. Then after I do that to prevent the streaks, just use baby oil. Put a tiny bit on a paper towel and wipe it over the doors. I learned this from online and from a pal that is in the navy. They can't have streaks on anything for navy inspections.

- Q: How are steel coils used in the manufacturing of automotive components?

- Steel coils are used in the manufacturing of automotive components by being formed and shaped into various parts such as frames, body panels, and suspension components. These coils are typically cut, stamped, and welded to create the desired shapes and sizes needed for the automotive industry.

- Q: How are steel coils used in the manufacturing of drivetrains?

- Steel coils are commonly used in the manufacturing of drivetrains as they provide the necessary strength and durability required for these critical components. The steel coils are typically formed into various shapes, such as gears, shafts, and axles, which are then machined and assembled to create the drivetrain system. These steel components help transfer power from the engine to the wheels, allowing the vehicle to move efficiently and smoothly.

- Q: What are the current trends in the steel coil industry?

- Some current trends in the steel coil industry include a growing demand for high-strength and lightweight steel coils, increased focus on sustainability and recyclability, advancements in technology for improved efficiency and productivity, and a shift towards automation and digitalization in manufacturing processes. Additionally, there is a rising preference for customized steel coil solutions to meet specific industry requirements.

Send your message to us

PPGI Prepainted Galvanized Rolled Steel Coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords