Pre-painted Steel Rolled/PPGI/Prepainted Cold Rolled Galvanized Steel Sheet Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Prime CGCC RAL DX51D Z60 Z100 Color Coated Steel/ PPGI/Color Prepainted Galvanized Steel Coil(China)

FOB Price: US $630 - 938 / Ton Get Latest Price

Min. Order Quantity: 15 Ton/Tons

Supply Ability: 5000000 Ton/Tons per year

Port: Qingdao, Tianjin, China

Payment Terms: L/C, T/T, Western Union

Contact Supplier

Company Information

Quick Details

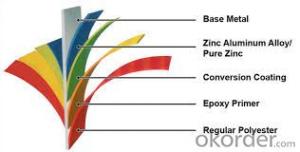

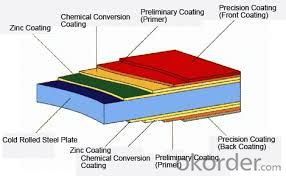

Standard: AISI, ASTM, BS, DIN, GB, JISGrade: SGCC SGCD SGCH DX51D/52D/53DThickness: 0.22-1.0 mm

Place of Origin: Tianjin China (Mainland)Model Number: CGCC CGCL PPGI PPGLType: Steel Coil

Technique: Cold RolledSurface Treatment: CoatedApplication: Container Plate

Special Use: Wear Resistant SteelWidth: 750-1250mmLength: Coil Or Sheet (780-6000 mm ) can be done as your requirements.

Exporting Ability: 500 20ft container/each monthZinc Coating: Z40--Z180g/m2Painting: Front side paint thickness: 15-25μ M (bottom paint + top paint)

Sample: Offer Free Sample For Quality TestContainer Info: One 20ft container can hold 26tons MaxColor: As the RAL color chart

Coil I. D: 508/610 mmCoil Weight: 3.5-8 tons/each coilOther Poducts: Cold rolled, galvanized steel coils

- Q: In construction, what types of stress require steel to be placed in footings?

- Steel is always added to concrete to handle local 'tension' stresses. (Sometimes to provide extra compression in 'pre-stressed' applications, but the steel is still in tension.) Steel would be added to the lower section of footings to stiffen them to 'bridge' local 'soft spots' in the substrate.

- Q: did bible stated that steel is coming from outer space. i mean meteor rocks that enter our earth sistem contains the minerals iron.

- Steel is not elemental, if that's what you mean. It's a metal alloy, a combination of mostly iron and some carbon. Iron and carbon both occur naturally on the Earth, but you have to melt them together to make steel.

- Q: so i've started learning to play guitar in the past few weeks, and i'm using my sister's old guitar which isn't in very good condition, so i'm planning on buying a new one, but which would be better to buy, nylon string or steel string?

- It rather relies upon on what type of music you're enjoying, nylon string guitars have a mellow, softer tone than steel strings, the feel of the nylon strings (a minimum of to me) are reliable, in my opinion, i might ought to declare nylon is extra suitable, large for finger choosing and a effective tone. once you're searching for a guitar, you are able to flow out to a close-by guitar save, and attempt the two out for your self, in straight forward terms then will you comprehend for specific.

- Q: How are steel coils used in the energy sector?

- Steel coils are used in the energy sector for various purposes, primarily in the construction and maintenance of power plants and transmission infrastructure. They are commonly used in the manufacturing of turbines, generators, and transformers due to their strength and durability. Steel coils are also used to fabricate pipelines and storage tanks, which are essential for transporting and storing oil, gas, and other energy resources. Additionally, steel coils play a crucial role in the construction of wind turbines, providing support and stability to these renewable energy sources.

- Q: What are the different types of steel coil handling equipment used during processing?

- There are several types of steel coil handling equipment used during processing, including coil cars, coil upenders, coil tilters, coil transfer cars, coil grabbers, coil lifters, and coil reels. These machines are designed to efficiently handle and maneuver steel coils of various sizes and weights, ensuring safe and smooth operations during the processing stages.

- Q: What are the different methods of slitting steel coils?

- Different methods exist for slitting steel coils, each with unique advantages and limitations. Several common methods include: 1. Rotary Shear Slitting: By employing rotating knives, this method cuts steel coils into narrower strips. It is versatile and efficient, enabling high-speed production and precise slitting. Rotary shear slitting is commonly utilized for thinner gauge materials. 2. Looping Pit Slitting: Steel coils pass through a looping pit in this method, where they are guided and tensioned before being slit. It is suitable for thicker gauge materials and ensures good edge quality. Looping pit slitting accommodates higher coil speeds and heavier coils. 3. Drag Slitting: In this method, the steel coil is dragged over a stationary blade or set of blades to perform the slitting. It is particularly beneficial for difficult-to-slit materials like high-strength steels. Drag slitting yields excellent edge quality and is often utilized for precision slitting applications. 4. Crush Slitting: Pressure is applied to the steel coil in crush slitting to crush and separate it into narrower strips. This cost-effective method is suitable for lower gauge materials but may result in slightly rougher edge quality compared to other methods. 5. Laser Slitting: Laser slitting employs a focused laser beam to cut through the steel coil. It is a highly precise method that offers excellent edge quality and minimal distortion. Laser slitting is commonly employed for high-value and specialty materials. Each method possesses distinct advantages and is suitable for specific applications and material types. The choice of slitting method depends on factors such as material thickness, desired edge quality, production speed requirements, and budget considerations.

- Q: How are steel coils used in the production of transportation systems?

- Steel coils are used in the production of transportation systems for various applications such as the manufacturing of automobile parts, railway tracks, and shipping containers. The coils are typically used to create strong and durable components that can withstand the harsh conditions and heavy loads associated with transportation.

- Q: What exactly is surgical stainless steel made of (metals)? Does it contain nickel? If so, what % does it usually contain? I am deciding between surgical stainless steel piercings or titanium. Both same price and looks. I want to know which one is more hypo-allergenic and generally nickel free.

- surgical stainless steel is an austenitic steel containing 18-20% chromium and 8-10% nickel. and some proportion of molybdenum. The word 'surgical' refers to the fact that these types of steel are well-suited for making surgical instruments: they are easy to clean and sterilize, strong, and corrosion-resistant. The nickel/chrome/molybdenum alloys are also used for orthopaedic implants as aids in bone repair, and as a structural part of artificial heart valves and other implants. However, immune system reaction to nickel is a potential complication. In some cases today titanium is used instead in procedures that require a metal implant which will be permanent. Titanium is a reactive metal, the surface of which quickly oxidizes on exposure to air, creating a microstructured stable oxide surface. This provides a surface into which bone can grow and adhere in orthopaedic implants but which is incorrodible after implant. Thus steel may be used for temporary implants and the more expensive titanium for permanent ones

- Q: What is the shelf life of steel coils?

- The shelf life of steel coils can vary depending on various factors such as the type of steel, its specific application, and the storage conditions. Generally, steel coils have a long shelf life as they are highly durable and resistant to corrosion. When stored properly, such as in a dry and controlled environment, steel coils can last for many years without any significant degradation in quality. However, it is important to note that certain types of steel, such as galvanized steel, may have a shorter shelf life due to the potential for corrosion if the protective coating is compromised. Additionally, if steel coils are exposed to extreme weather conditions, high humidity, or chemicals, their shelf life may be reduced. To ensure the longevity of steel coils, it is recommended to store them in a covered area to protect them from moisture and direct sunlight. Proper stacking and handling techniques should also be followed to prevent any damage that could lead to premature deterioration. Ultimately, the shelf life of steel coils can vary, but with appropriate storage and handling, they can remain in good condition for an extended period, making them a reliable and long-lasting material for various applications.

- Q: I was watching a documentary on the samurai vs the European knight. It said that the when Japan was being invaded by the (cant remember) they needed a new weapon. The enemies armor made iron swords useless. While steel swords broke when in combat. So to combat this the Japanese made a hybrid sword. They used a special mold that made the swords back iron while the part that makes contact with the enemy was steel. Also the sword was curved so it increased its armor and cutting power. This revolutionary design made the the sword stronger. The iron back made it not break while the steel edge made it cut through the enemies armor. I want to know how iron is stronger than steel, and how steel can cut better than iron.

- This Site Might Help You. RE: Why is iron stronger than steel? I was watching a documentary on the samurai vs the European knight. It said that the when Japan was being invaded by the (cant remember) they needed a new weapon. The enemies armor made iron swords useless. While steel swords broke when in combat. So to combat this the Japanese made a hybrid...

Send your message to us

Pre-painted Steel Rolled/PPGI/Prepainted Cold Rolled Galvanized Steel Sheet Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords