Prepainted Galvanized Steel Coil PPGI Galvanized Steel in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Bried Introduction:

1).Colr steel is coated with organic layer, which provides higher anti-corrosion property and longer lifespan than that of galvanized steel sheets.

2).The base metals for color steel consist of cold rooled. HDG lectro-galvanized and hot-dip alu-zinc coated steel. The finish coats for color tels can be classified into groups as follows: polyester, silicon modiied polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3).The production process has evolved from one-coating-and-oe-baking to double-coating-and-double-baking, and even three-coatig-and-three-baking.

4).The color of the color steel has a very wide selection, like orange, creamcolored, dark sky blue, sea blue, bright red, ivory white, procelain blue, etc.

5).The color teels can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

2. Steel coil, prepainted steel coil,prepainted galvanized steel coil Advantages:

(1).High strength, Good corrosion

(2).Well rainproof performance

(3). Easy to install and remove

(4).Competitive price with best quality

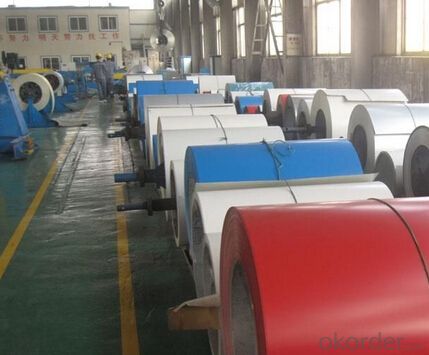

3.Image of prepainted steel coil:

4.Data of prepainted steel coil:

| Item | Galvanized Steel Coil |

| Inside Diameter | 508mm Or 610mm |

| Outside Diameter | 1000-1500mm |

| Zinc Coating | Z50-Z275G |

| Painting | Top: 15 to 25 um (5 um + 12-20 um) back: 7 +/- 2 um |

| Delivery Details | Within 10days after receipt of the contract |

| Packaging | as your requirements |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What are the dimensions of steel coils used in the metal furniture industry?

- The dimensions of steel coils used in the metal furniture industry can vary depending on the specific requirements of each manufacturer. However, commonly used dimensions include coil widths ranging from 24 to 60 inches (61 to 152 cm) and coil diameters ranging from 36 to 72 inches (91 to 183 cm). The thickness of the steel coils can also vary, typically ranging from 0.020 to 0.250 inches (0.05 to 0.64 cm). These dimensions allow manufacturers to efficiently produce various types of metal furniture, such as chairs, tables, and cabinets, by utilizing the steel coils as raw materials for their production processes.

- Q: is stainless steel a good steel for sensitive skin? or does it have to be surgical or sterling silver?

- idk about sensitive skin but i have stainless steal in i think right now. im sure any are good for a healed belly piercing, if it hasnt been 3 monthes yet then id stick with a surgical

- Q: How are steel coils used in construction?

- Steel coils are commonly used in construction for a variety of purposes, such as forming the structural framework of buildings, manufacturing steel beams, and reinforcing concrete structures. The coils are unraveled and shaped into different forms, allowing them to provide strength, stability, and durability to the construction projects.

- Q: I made a wood crossbow body but all I need is a bow which I want to be metal. I've used a thin steel sheet that I cut to appropriate size but when it bent with the string strung, it never went to original shape after being shot. I used a slightly thicker and it wouldn't bend at all. Anybody know what thickness and type to use? Any real answers are very appreciated. Thanks.

- So i do know way more about compound bows than I do about crossbows, but i'm going to enterprise an opinion. For my part, i would probably lean toward the compound bow. A part of it's only that i like them higher. However, moreover to that, more often than not when you find yourself hunting you will carry the crossbow loaded, on the grounds that the are typically awkward to load when you have the shot. If you're hunting from a blind or from a tree stand (and might figure out easy methods to load the item whilst you're up there) that's almost always ok. But when you need to tote a crossbow round whilst it's loaded, that may be a bit dicier proposition. Most crossbow safeties are lovely crude making the likelihood of by chance firing one alot bigger than with a rifle. Now, to the plus facet, a crossbow has essentially the entire upside of firing a rifle - best accuracy, same ergonomics, can run a scope on them. Without the downside - no real recoil, no longer too loud and you simply have a lovely excellent trigger on about any of them. Compounds are way more work. Plus it is much tougher to be accurate under stress with a compound than a crossbow. Regarding the protection? Don't particularly find out about that. After I was once doing shooting alot of archery, my 3 - D bow for outdoor stuff was once at ninety two pounds with a fifty five% letoff. My goal bow was once round 60. I had to pretty on the whole take care of string stretch, and tuning with the three - D bow. So i'd expect a crossbow to be in that regional. 5 hours to your nearest Bass pro? Good for a crossbow perhaps it's valued at it because no longer too many places raise them. Nonetheless, should you do back to a compound bow it appears rough to feel that would be your nearest archery professional shop. Thinkingblade

- Q: Steel or stainless steel

- Steel often has impurities that can generate fumes, which cause a fever identical to smoke inhalation. You always need to be concerned about what you are breathing around hot metal.

- Q: How are steel coils inspected for surface defects?

- Steel coils are inspected for surface defects using various methods such as visual inspection, magnetic particle testing, eddy current testing, and ultrasonic testing. These techniques help identify any imperfections or flaws on the surface of the steel coils, ensuring they meet quality standards before they are further processed or shipped to customers.

- Q: I was curious to what type of steel I should get if I wanted something that kept its edge longer than 154cm but is still just as stainless. I don't know much about knife steels inform me please?

- If you want a good quality knife, stay away from Stainless, I would suggest one that is a mix of high and low carbon steel, high carbon holds the edge, but is brittle, low carbon is more malleable, which prevents from breaking when used.

- Q: What are the common surface finishes available for steel coils?

- There are several common surface finishes available for steel coils, depending on the desired application and aesthetic requirements. One of the most common surface finishes is hot-dip galvanized, which involves coating the steel coil with a layer of zinc. This finish provides excellent corrosion resistance and is commonly used in outdoor applications where the steel is exposed to moisture and harsh weather conditions. Another popular surface finish is electro-galvanized, which is achieved by applying a thin layer of zinc to the steel coil through an electroplating process. This finish also provides good corrosion resistance but is generally not as durable as hot-dip galvanized. Additionally, steel coils can be coated with a layer of paint or polymer to enhance their appearance and provide additional protection against corrosion. These coatings can be applied in various colors and finishes, such as matte or glossy, to suit specific aesthetic requirements. Furthermore, steel coils can undergo a process called mill finish, which involves leaving the steel in its raw and untreated state. This finish is often used when the steel coil will undergo further processing or coating at a later stage. Other surface finishes for steel coils include stainless steel finish, which is achieved through a passivation process to enhance the steel's resistance to corrosion, and brushed or polished finishes, which are typically used for decorative purposes. Overall, the choice of surface finish for steel coils depends on factors such as the intended use, environmental conditions, and desired appearance, with each finish offering its unique advantages and characteristics.

- Q: Can one assume that stainless steel that can be hardened is magnetic?

- Most of the 300 series stainless metals are not magnetic, but if it is cast, it is magnetic. Welds are considered casting, so the welds are magnetic even though the items that are welded together are not. The 400 series stainless may have a few types that are magnetic. I suppose generally the hardenable factor has a bearing if you consider that 400 series can be hardened more readily than the 300 series. Source: Working in metal fabrication shops.

- Q: No. Not Stainless steel, I mean STEEL.Not a specific type, but STEEL.Thanks. xo

- This Site Might Help You. RE: Is Steel a Pure Substance or a Mixture? No. Not Stainless steel, I mean STEEL. Not a specific type, but STEEL. Thanks. xo

Send your message to us

Prepainted Galvanized Steel Coil PPGI Galvanized Steel in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords