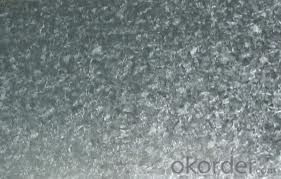

PPGI/High Quality Manufacturer Pre-Painted Steel Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Specification:

1) Standard: JIS G3302-1998/EN10142/ASTM A653/ASTM A792/ AISI/BS/ DIN/GB

2) Grade:DX51D+Z

3) Thickness: 0.12mm-0.6mm, all available

4) Width: 600mm-1250mm, all available

5) Length: according to the customer's request

6) Coil ID: 508/610mm

7) Hardness:Soft,full hard

8) Zinc Coating: 50-150g

9) Paint coating: Top 15-20mirco ,back 7mirco

10) Color series: Sea blue,white grey and all RAL color

PPGI,(PPGL,pre-painted galvanized steel coils, pre-painted galvalume steel coils,color coated steel coils.color coated galvanized steel coils)

1, Introduction: PPGI is made of galvanized steel coils or galvalume steel coils with polymer coatings as surface. It's a new enclosure material and building board

2, Product feature: Apperance of a variety of color Antirust and antiseptic,durability,etc.

3, Production Process: Pretreatment(Degreasing) DryingChromatingPaint Basic OilCoolingDryingColor CoatingCoolingFilm- coveringRolling Up

4, Application: it is ideal for a wide range of applications,, such as pre-engineered buildings, architectural panels, roofing, siding, cladding, and many other building components.and also used back plate of appliance; wide range of construction, furniture industry, transportation industry, etc.

- Q: How do steel coils contribute to sustainable construction?

- Steel coils contribute to sustainable construction in several ways. Firstly, steel is a highly durable and long-lasting material, which means that structures built using steel coils have a longer lifespan and require fewer repairs and replacements. This reduces the overall environmental impact of construction by minimizing waste and resource consumption. Additionally, steel is a highly recyclable material, and steel coils can be easily recycled at the end of their life cycle, reducing the need for new steel production and conserving natural resources. Furthermore, steel is a fire-resistant material, providing enhanced safety and reducing the risk of structural damage during fire incidents. Overall, the use of steel coils in construction promotes sustainability by minimizing environmental impact, conserving resources, and ensuring the longevity and safety of structures.

- Q: Steel sticks- it has meaning to us -similar to my deceased father's name, Steven fits our style as people. We like the hardness of it for our little man. We need a middle name though. Open to suggestions, thank you=)

- Steel ___ Tompkins xavier jax stone blaise/blaze navarro dialo zorion soloman eron muron darko vincent wolf giovanni ryker/rykeir orvall oryan/orian isadore reese axel/axl xander/zander zane zeke dane xan/zan grayson griffin trayton urban sterling - probably wouldn't sound good with steel but its another choice you can have STOP HATING SHE SAID SHE DIDNT LIKE COMMON NAMES!

- Q: Looking for an insight here into what hiking with steel toe-capped boots would be like, as I saw a nice pair of steel toed magnums that I plan to use for my future hiking (which I will be doing a fair amount of in the future). They seemed fairly comfortable, but I am curious into what others have to say and what might be known of this sort of approach. Thanks in advance.

- Steel toed boots are very heavy compared to hiking boots, after a long hike (especially in rough terrain) the extra weight is gonna tire you out. Steel toes are made for things like construction, or doing a task where extra protection of the toe is needed. So it's not ideal, but whatever floats your boat man (better than wearing tennis shoes). I personally have Converse composite toed boots from my airsofting days and since im too cheap to buy dedicated hike boots, I use it for hiking. Its supposedly made for military use and is much lighter than steel toe. But WAIT!!! lets say you dont have a gun or knife and you run into a pissed off Sasquatch, a steel toe boot too the nutz would do well in puttin the hurt on the dude.

- Q: why were guns, germs and steel absent within America?

- i dont really understand this question but if it means to how it was before then it was absent because the native americans were not into technology so they obviously had no guns created that was something that they had traded to get from europe as for the germs i ddo not know about thta really except for if it means that common disease and one of the diseases most used in history books is malaysa from mosquitos but when they had traded with europe they got all sorts of diseases now for steel the only reason i remember them traveling for is for gold and i dont remember them ever looking for it until 13 colonies were established as you can see im not exactly sure about germs and steels but i know that the guns part is correct

- Q: How are steel coils used in the manufacturing of electrical wiring?

- Steel coils are used in the manufacturing of electrical wiring as a core material for cable reinforcement. The coils provide structural strength and support to the wires, ensuring durability and resistance to external forces. Additionally, the steel coils help in maintaining proper electrical conductivity and minimize electrical losses, ensuring efficient power transmission and distribution.

- Q: How long can steel coils be stored?

- Steel coils can be stored for an extended period if proper storage conditions are maintained. The duration of storage depends on factors such as coil quality, environmental conditions, and any specific storage requirements determined by the manufacturer.

- Q: What are the common coil packaging materials?

- The common coil packaging materials include steel strapping, stretch film, polypropylene strapping, and HDPE (high-density polyethylene) sheets.

- Q: Can steel coils be coated with anti-corrosive substances?

- Yes, steel coils can be coated with anti-corrosive substances to protect them from rust and corrosion.

- Q: What are the common methods of painting or coating steel coils?

- One common method of painting or coating steel coils is through the process of coil coating. In coil coating, the steel coils are first cleaned and pre-treated to remove any contaminants and improve adhesion. Then, a primer or a base coat is applied to the coils to provide a foundation for the final coating. This primer helps in protecting the steel from corrosion and improves the overall durability of the coating. After the primer is applied, the steel coils pass through a series of rollers where the topcoat is applied. The topcoat can be a variety of materials such as polyester, polyurethane, or fluoropolymer, depending on the desired properties of the final coating. These topcoats provide the desired color, gloss, and protection against weathering, chemical exposure, and UV radiation. Another common method of painting or coating steel coils is through the process of electrostatic spraying. In this method, a paint or coating material is atomized into fine droplets and then charged with an electrical charge. The steel coils, which are grounded, attract the charged droplets, resulting in an even and controlled application of the paint or coating material. Powder coating is yet another method used for painting or coating steel coils. In this process, a dry powder is electrostatically charged and sprayed onto the steel coils. The charged powder adheres to the surface of the steel due to electrostatic attraction. The coated steel coils are then heated, causing the powder to melt and form a continuous film, providing a durable and resistant coating. Overall, these methods of painting or coating steel coils offer a wide range of options in terms of color, finish, and performance characteristics. The choice of method depends on factors such as the desired appearance, level of protection needed, and the specific requirements of the intended application.

- Q: How are steel coils used in the production of agricultural machinery?

- Steel coils are used in the production of agricultural machinery to create various components and parts such as frames, brackets, and structural supports. The coils are typically cut, shaped, and welded to form these components, providing strength, durability, and stability to the agricultural machinery.

Send your message to us

PPGI/High Quality Manufacturer Pre-Painted Steel Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords