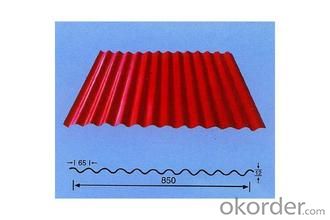

Prepainted Galvanized Corrugated Steel Plate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 250 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | standard seaworthy packing: full iron packing, lined with moistureproof paper packed in iron sheet lined with kraft paper or as per client's request. |

| Delivery Detail: | within 35 days after receiving the down payment |

Specifications

1.size:0.16-0.7*750-1250mm

2.color:in the light of RAL standard

3.material:SGCH

4.depth:15-18mm,pitch:75-78mm

5.good quality

product detal description:

Thickness | 0.16-0.7mm |

Width | 750-1250mm |

Length | 1700-3660mm |

Zinc coating | 30-60g/m2 |

Pitch | 76mm |

Wave height | 18mm or as request |

Wave No. | 8-12 |

Type | steel plate |

Weight of each package | about 3 mt |

Technology | cold rolled |

Material | SGCC SGCH |

Standard | ASTM,GB,JIS,DIN |

Price | FOB XingangUSD800-1300 per mt |

Packing | packed in iron sheet lined with kraft paper or as per client's request. |

Delivery time | within 35 days after receiving the down payment or irrevocable L/C at sight

|

Payment | 30% down payment of the total value by T/T and the balance must be paid by T/T or irrevocable L/C at sight after the goods finished. |

Application | it is widely used in construction, factory warehouse,etc. |

- Q: Can't find it- this is for a physics experiment for youngs modulus done with a steel wire.

- This Site Might Help You. RE: what is the elastic limit of steel in Nm^2? Can't find it- this is for a physics experiment for youngs modulus done with a steel wire.

- Q: What are the different types of steel coil treatments?

- Enhancing the properties and performance of steel coils involves various types of treatments. The treatments include: 1. Heat treatment known as annealing. It involves heating the steel coil to a specific temperature and gradually cooling it. This treatment alleviates internal stresses, enhances ductility, and boosts the overall strength of the coil. 2. Chemical treatment called pickling. It entails submerging the steel coil in an acid or chemical solution to eliminate impurities, scale, and rust from the surface. This treatment enhances the surface finish and cleanliness of the coil. 3. Application of a protective coating such as oil. A thin layer of oil or another protective substance is applied to the surface of the steel coil. This treatment prevents corrosion, improves lubricity, and safeguards the coil during storage and transportation. 4. Galvanizing, a process that involves coating the steel coil with a layer of zinc. This protective layer shields the coil from corrosion, creating a barrier between the steel and the surrounding environment. It ensures long-term durability and resistance to rust. 5. Tempering, a heat treatment process that includes heating the steel coil to a specific temperature and swiftly cooling it. This treatment enhances the toughness and strength of the coil, making it more resistant to impact and deformation. These are just a few instances of the various types of steel coil treatments commonly employed. Each treatment has its own unique purpose and advantages, and the choice of treatment will depend on the desired properties and applications of the coil.

- Q: how is stainless steel made? what are the things used in making it?

- There are 3 basic stainless steels. The Martinsitic, the ferritic, and the Austinistic. The spelling may be wrong on all of them. (Got out of school in 1966 with my metallurgy in 1965. The Ferritic is magnetic and has some resistance to corrosion but the Martinsitic is much more resistant to corrosion. The Austinitic stainless is very resistant to corrosion. The differences are the amount of Chrome and Nickel in the batches. The Austinitic has an 18/8 ratio of Chromium and Nickel with the rest Iron and minor ingredients. The carbon content is very important and these steels are often made in small batches with close monitoring of composition and carbon content. Scrap metals are frequently used with the chrome and nickel being added as carefully selected scrap or even fresh crude stocks. Electric melting is frequent to avoid contamination.

- Q: Building the bulwurk, general use on trawlers. What kind of steel is best suited.

- How big is your trawler going to be and what use, The ones you see off the Alaska Coast or a Gulf Coast Shrimper? My preference in today's economy would not make sense and that is Aluminum.....not steel at all, maybe even Fiberglass, but $$$$ talk so Steel is cheaper, but you need to know what you are doing. The designer of the hull should have specified the right /preferred grade. It today's world there are many more choices available. You use a mild steel, most often grade A or B, but some applications call for grade D. Check your blue prints and list of materials. Edit. Ok I understand. There are 2 ways to go. One is use a relatively cheep steel and use higher cost epoxy primers and paint, often requiring special surface preparation just before priming, or two, using a much higher cost steel with more chrome and nickel in it. Grades that begin with #3xxx These are weldable with rods that are available, and can be welded directly to mild steels. However these are 3X the cost. If your a Shrimper, I'm guessing gulf coast. I worked with several boat yards in the 70's installing spray urethane foam for insulating there holes. So I've been around lots of small yards from Florida to Texas. I'd call the nearest steel warehouse and ask what they would recommend. You might find what you want at a scrap yard. I've lucked out several times picking up 1/4 plate scrap$ and I'd bet the scrapyard guy would know just what you need. I know there are places to get what you need in Mobile and New Orleans. Good luck!

- Q: How are steel coils used in the manufacturing of shipbuilding?

- Steel coils are used in shipbuilding as they are a primary source of high-quality steel that is necessary for constructing the various components of a ship, such as the hull, decks, and superstructure. These coils are processed and shaped into plates, beams, and other structural elements, which are then assembled to form the framework of a ship. The strength and durability of steel coils make them ideal for withstanding the harsh conditions at sea and ensuring the structural integrity of the vessel.

- Q: is red steel any good??????? not sure im really impressed but im not really into fighting games but it looks cool.... so whats your views guys???????anyone bored of smooth moves yet?anyone think the new sonic is bit cra ppy !!!!!!!!!!! darn them any new goooood games coming oput on the wii??

- Trauma center is awesome. Red steel isn't bad. Same as any other FPS except with a pointer... It's no half life, but its not terrible. Multiplayer is highly entertaining though. Especially if you can get four people playing mystery mode. Trust me, its worth the effort of getting them together. Like the other guy said, rent it. I wouldn't buy it.

- Q: Where are the coils and the steel plates used? Where did the steel plate come from?

- The use of steel coils, refrigerators, washing machines, household appliances, and other industries, parcels are winding.Steel plates can also be found everywhere: airplanes, guns, trains, ships, space shuttles, spaceships, automobiles, etc..Steel plate through mining - sintering - iron smelting - smelting - forming.

- Q: Apparently, this has to do something with electrochemical cells.

- Steel wool is a mild abrasive. I don't know what it is you are cleaning, but it is probably to remove any coating or oxidisation from the metal. Maybe you are using a metal for an electrode (perhaps a steel nail pushed into a lemon?).

- Q: How do steel coils contribute to the HVACR industry?

- The HVACR industry relies heavily on steel coils, which play a vital role in various applications. These coils, typically made from durable and corrosion-resistant materials like stainless steel or galvanized steel, ensure longevity in demanding HVACR environments. Air conditioning systems commonly use steel coils to transfer heat between the refrigerant and the surrounding air. These coils, also known as evaporator coils, absorb heat from indoor air, cooling it down and removing moisture. The heat is then released outside through a condenser coil, enabling efficient cooling and dehumidification. Heat exchangers, crucial components in HVACR systems, also utilize steel coils. These coils, often in the form of finned tubes, provide a large surface area for efficient heat transfer, enhancing overall system efficiency. In the construction of ductwork, steel coils are extensively employed. These coils are shaped and sized to fit specific ductwork designs, ensuring optimal airflow and temperature control. Their durability and strength allow them to withstand the pressure and forces exerted by airflows in duct systems. Refrigeration systems rely on steel coils to transfer heat out of enclosed spaces, such as refrigerators or freezers. These coils, called condenser coils, release heat from the refrigerant as it changes from a high-pressure gas to a high-pressure liquid. Steel coils are essential in the food service and cold storage industries, where they enable the cooling and preservation of perishable goods. Overall, steel coils significantly contribute to the HVACR industry by facilitating efficient heat transfer, optimal temperature control, and reliable operation of various systems. Their durability, corrosion resistance, and versatility make them crucial components in providing comfortable and controlled environments in residential, commercial, and industrial settings.

- Q: I want a stainless steel refrigerator that doesn't leave fingerprints and I'm looking on Lowe's website but they have too many choices and i don't have a clue what they are. The have stainless, stainless look, stainless steel, monochromatic satina, and monochromatic stainless steel. Can anyone tell me what the heck those mean? lol

- Stainless Look vs Stainless in refrigerators usually refers to true Stainless Steel versus Satina. There's pluses and minuses both ways actually. With true Stainless, you have the exact match to the rest of the kitchen (because Satina is only used on refrigeration), but it is more prone to fingerprints, and is not magnetic. The Satina finish has a good look when not directly near a Stainless appliance, and does not show fingerprints and will accept magnets, but is not an exact match to stainless. My usual recommendation is that if you have a kitchen full of Stainless products, stick with the true Stainless Steel. If the refrigerator is more isolated, or is the only thing you want to have a Stainless look, you may want to consider Satina. If you put a lot of magnets on the refrigerator, I'd also recommend to go Satina. And since you don't want fingerprints, the Satina steel might come to your liking.

Send your message to us

Prepainted Galvanized Corrugated Steel Plate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 250 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords