prepainted Galvanized Corrugated plate / sheet in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of cold rolled steel coil :

The raw material of cold rolled steel coil/sheet is high quality hot rolled product, and after pickling, kinds of new technology and new process of global cold rolling production have been applied. Therefore the manufacturing, home appliance, automobile etc.

Characteristic cold rolled steel coil :

1. Refrigerators, cabinets, power distribution baords and drums.

2. Automobile floor and roof panels.

3. Automobile fenders and quarter panels

4. Automobile fenders and quarter panels

Specification of cold rolled steel coil :

prepainted corrugated steel plate | |

material | galvanized steel sheet |

prepainted galvanized sheet | |

model No. | types of roof sheets |

sheet thickness | normal use 0.3-0.6mm |

length | any length, according to the transportation, generally less than 12m |

color | standard color:red, blue, white, grey |

special color: according to RAL color | |

characteristic | 1:weather proof |

2:heating insulation | |

3:fireproof | |

4:anti-rust | |

5:sound insulation | |

6:long life span: more than 15 years | |

advantages | 1.low foundation cost |

2.easy construction | |

3.time saving | |

4.labor saving | |

application field | 1:construction:prefabricated house, steel house, mobile house, modular house, villa, bungalow design, portable house/carbin, ready made house, kiosk booths, steel building... |

2:container manufacturing | |

3:household appliances and furniture | |

4:vehicle and vessel manufacturing | |

5:others,like machinery structual parts, manufacturing shells of motors and so on | |

packing | plastic film, pallet or as your request |

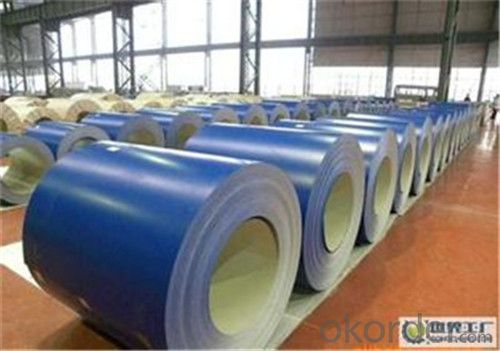

Images of cold rolled steel cold rolled steel coil:

FAQ

1.What's your MOQ?

50MT, it is for one container.

2.Whether your company have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the

- Q: Are steel sheets suitable for exterior cladding?

- Yes, steel sheets are suitable for exterior cladding. They are durable, weather-resistant, and provide a sleek and modern appearance to buildings. Additionally, steel sheets offer great strength and can withstand harsh environmental conditions, making them a reliable choice for exterior applications.

- Q: Are steel sheets suitable for fire-resistant applications?

- Yes, steel sheets are suitable for fire-resistant applications. Steel is known for its excellent fire resistance properties. It has a high melting point and does not easily ignite or contribute to the spread of fire. Steel sheets can be used in various fire-resistant applications such as fire doors, fire-rated walls, and fireproof enclosures. Additionally, steel sheets can be combined with other fire-resistant materials, such as fire-resistant coatings or insulation, to further enhance their fire resistance. Overall, steel sheets are a reliable choice for fire-resistant applications due to their durability, strength, and ability to withstand high temperatures.

- Q: What are the different types of steel sheet finishes for automotive applications?

- Automotive applications commonly utilize various types of steel sheet finishes. These finishes are applied to the surface of the steel sheet for the purpose of enhancing its appearance, durability, and resistance to corrosion. The mill finish, for instance, is a natural finish that the steel sheet attains after undergoing hot or cold rolling. It possesses a dull gray appearance and is typically employed in applications where aesthetics are not of paramount importance. On the other hand, the galvanized finish is a favored choice, whereby a layer of zinc is coated onto the steel sheet to safeguard it against corrosion. This finish exhibits exceptional resistance to corrosion and is frequently utilized in automotive body panels and structural components. Another option is the painted finish, which involves coating the steel sheet with a layer of paint. This finish improves both the aesthetics and corrosion protection of the steel sheet. Painted finishes are available in a variety of colors and textures, offering customization and branding possibilities. Furthermore, specialized finishes, such as the electro-galvanized finish, are also available. This finish involves the application of a thin layer of zinc to the steel sheet through an electroplating process. It provides enhanced corrosion resistance and is commonly employed in automotive parts that necessitate a high level of rust protection. Lastly, the brushed or polished finish entails mechanical polishing of the steel sheet surface to create a smooth and reflective appearance. This finish is often used for decorative purposes in automotive applications, like trim or accents. In conclusion, the range of steel sheet finishes for automotive applications includes mill finish, galvanized finish, painted finish, electro-galvanized finish, and brushed/polished finish. Each finish offers distinct advantages in terms of appearance, durability, and corrosion resistance, enabling manufacturers to select the most suitable option for their specific automotive application.

- Q: What is the thickness of the paint board?

- Paint boards are generally used in cabinets or doors and other places, we have often seen, but also understand some of the paint plate thickness of how much better? Paint board is a kind of woodworking materials. It is based on density board as base material, the surface after six to nine times (not the same as the number of Polish manufacturers are different, the more the number of process requirements is high, the cost is higher), the primer, drying, polishing (at the end of three, two, light) high temperature baked. At present, mainly used in cabinets, doors and so on. Paint board can be divided into light, Matt and metal paint three. At present, there are the latest engraving baking paint board, Newcastle house paint baking board and so on.

- Q: Are the steel sheets available in different grades?

- Different grades of steel sheets are available. Steel is categorized into various grades depending on its composition, strength, and other properties. These grades encompass carbon steel, stainless steel, alloy steel, and tool steel, among others. Each grade possesses distinct characteristics and is appropriate for different applications. The selection of a grade relies on factors such as the desired strength, resistance to corrosion, and cost-effectiveness for the particular use. Consequently, when buying steel sheets, it is crucial to take into account the grade that most effectively meets the intended purpose.

- Q: How do steel sheets compare to aluminum sheets in terms of strength?

- Steel sheets are generally stronger than aluminum sheets in terms of strength. Steel has a higher tensile strength and can withstand higher loads and impacts compared to aluminum. However, aluminum sheets are lighter and have better resistance to corrosion, making them suitable for certain applications where weight and corrosion resistance are important factors.

- Q: What is the process of applying weather-resistant coatings to steel sheets?

- The process of applying weather-resistant coatings to steel sheets typically involves several steps. First, the steel sheets are thoroughly cleaned and prepped to remove any dirt, rust, or previous coatings. This is usually done through a combination of mechanical cleaning, such as sandblasting or grinding, and chemical cleaning with solvents or acids. Once the surface is clean, a primer or base coat is applied to enhance adhesion and corrosion resistance. The primer is usually chosen based on the specific requirements of the application, such as the type of weather conditions the steel sheets will be exposed to. After the primer has dried or cured, the weather-resistant topcoat is applied. This topcoat is specially formulated to withstand harsh weather conditions, such as UV radiation, moisture, temperature fluctuations, and chemical exposure. The topcoat is typically sprayed onto the steel sheets using airless spray equipment to ensure an even and smooth application. Finally, the coated steel sheets are cured or baked at a specific temperature for a specified period of time. This curing process helps the coatings to fully bond and provides optimum performance. Overall, the process of applying weather-resistant coatings to steel sheets requires thorough cleaning, priming, topcoating, and curing to ensure optimal protection and durability in various weather conditions.

- Q: Can steel sheets be used for manufacturing shipping containers?

- Indeed, the utilization of steel sheets in the production of shipping containers is possible. Steel, being a robust and durable material, offers exceptional structural resilience, rendering it an ideal choice for the construction of shipping containers. Typically, steel sheets are employed in fabricating the container's walls, roof, and floor, guaranteeing its ability to endure the demanding conditions of transportation and safeguard the goods contained within. Moreover, steel exhibits resistance to diverse weather conditions, corrosion, and pests, thereby establishing it as a trustworthy option for the manufacturing of shipping containers.

- Q: Can the steel sheets be used for soundproofing applications?

- Yes, steel sheets can be used for soundproofing applications. Steel is a dense and sturdy material that can effectively block and absorb sound waves. By using steel sheets as a barrier or enclosure, they can help reduce the transmission of sound from one space to another. Additionally, steel sheets can be combined with other soundproofing materials such as insulation or acoustic panels to further enhance their soundproofing capabilities. However, it is important to note that the thickness and quality of the steel sheets will play a significant role in their effectiveness as soundproofing materials.

- Q: What are the different types of steel sheet finishes?

- There are several different types of steel sheet finishes, including mill finish, brushed finish, mirror finish, galvanized finish, and painted finish.

Send your message to us

prepainted Galvanized Corrugated plate / sheet in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords