Prepainted galvanized Rolled Steel Coil -CGLCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

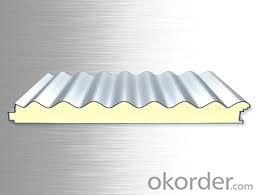

Description: Prepainted Galvanized Steel usually refers to have substrateprocessed with surface processed and coated then(roller coated )or bonded organic thin film and baked, and it is able to be processed tofinal prodevtion . PrepaintedGalvanized Steel qualified with excellent decorative ,formability ,corrosionresistance ,coating adhesion ,can keep for a long time as well as maintainfresh color .For color coated steel sheet can obtain good economicbenefit by steel belt wood ,efficient in construction and save energy ,preventpollution etc.Which is an ideal material;for manufacturing board. Applications: It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making steel roofing,insulation panel, corrugate sheet, facade wall,shutters,T-bar and home appliance. Packaging & Delivery: The packing of coils consists of anti-damp paper, PVC film, hardboard paper, steel box, strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye to the side) or wooden pallets(eye to the sky). Images:

|

- Q: How are steel coils used in the production of steel hooks?

- Steel coils are used in the production of steel hooks as they serve as the primary raw material. These coils are unrolled and then undergo a series of processes such as cutting, shaping, bending, and welding to form the desired shape of the hook. The strength and durability of steel coils make them an ideal material for manufacturing steel hooks, ensuring they can withstand heavy loads and provide reliable support in various applications.

- Q: What is the role of steel coils in the manufacturing of appliances?

- Steel coils play a crucial role in the manufacturing of appliances as they serve as the primary material for constructing the appliance's body and various components. The coils are processed, shaped, and transformed into different parts, such as the outer casing, inner structures, and internal components, providing strength, durability, and stability to the appliances. Additionally, the steel coils can be easily customized to meet specific design requirements, ensuring the appliances are efficient, reliable, and capable of withstanding the demands of daily use.

- Q: For the purpose of blade crafting. I need to heat treat this low quality steel i got.It's ASTM A36Is heat treatable and temperable?

- A36 is plain carbon structural steel. A36 could almost be considered junk steel. It is not suitable for cutting tools in any respect, as it is far to soft to hold an edge. A36 generally cannot be heat-treated, A36 can only be strengthened by cold-working, and even then, only up to about 60,000 psi. Heating the steel will only make it softer. The only real virtue of A36 is that it's easy to work with, it's easily cut and machined and it is very easy to weld. This is good for making steel structure, but not for knives. Probably the most popular material for knife blades is type 440C stainless. 440C is easy to work with in the un-treated state, and the heat treatment procedure is relatively simple.

- Q: How are steel coils used in the production of steel clips?

- Steel coils are used in the production of steel clips by being fed into a stamping machine, which cuts and shapes the coils into the desired size and shape of the clips.

- Q: ive made lots of knives but they are dark and not shiny. how do i polish a knife and make it shiny

- If the steel knife is dark and not mirror-shiny, then it is probably carbon steel and not stainless steel. If they are carbon steel, then you cannot polish it to a mirror finish - sorry. If there's any rust on them, you can use a very-fine grit sandpaper to remove. Do not put carbon steel knives in the dishwasher, and dry them thoroughly after hand-washing. For long-term storage (meaning you don't plan to use the knife within the next few weeks), wipe the blade a bit with some mineral oil, then store the blade portion of the knife in a plastic bag.

- Q: a picture of the atomic structure of carbon steel

- This is actually a quite complex question... The atomic arrangement in steels can be controlled over a pretty wide range of different structures. This is really the fundamental reason why steel is such a commonly used material. The different atomic structures produce different physical properties so metallurgists have developed many different processes to control the atomic structure to get the properties they want. One simple answer is that Fe is BCC, body centered cubic at room temperature at equilibrium conditions. When you heat Fe up, it transforms to FCC, face centered cubic. If you continue heating Fe, it goes back to BCC, then it melts. The addition of C makes these structures (and the transformation temperatures) different. Deviating from equilibrium conditions by, for example, cooling very quickly (quenching) creates different atomic structures (one of the most important is known as martensite). Depending on how much C is in the steel, you can also have two different atomic structures (two different phases) present in equilibirum, for example, pearlite which is a mix of alpha Fe (BCC) and iron carbide Fe3C (orthorombic crystal structure). So... you need to think a little more about exactly what you want a picture of. I hope this helps

- Q: Is it faster to smith steel or mithril in Rinescape assuming I'm going to mine everything myself?Mining level: 76Smithing level: 55

- steel, it will take you way to long to mine mithril ore, and all the coal. also if you make steel plate bodies they actually sell becuase people use it to make steel titian pouches

- Q: How are steel coils processed into finished products?

- Steel coils are processed into finished products through a series of steps including uncoiling, leveling, cutting, shaping, and surface treatment. The uncoiling process involves unwinding the steel coil to create a flat sheet. Next, leveling machines remove any unevenness in the sheet's surface. Then, the sheet is cut into desired lengths or shapes using cutting machines. Shaping processes such as bending, rolling, or stamping are performed to achieve the desired product form. Finally, surface treatment techniques like galvanizing, painting, or coating are applied to enhance the product's durability and appearance.

- Q: I also heard Stainless holds up better againts rust, blue steel needs more care.

- They have different properties. Bluing on steel is a surface treatment that helps inhibit rust, but doesn't prevent it. It will wear off with use over time, but can be redone. Stainless steel refers to a particular type of steel alloy, usually incorporating nickel and chromium, that is highly resistant to rust on its own, so doesn't need a surface treatment. Because the steel itself is what is rust resistant, that property can't wear off. All other things held equal, the carbon steel that bluing is typically applied to tends to be slightly more rigid and brittle than stainless steel. It may hold an edge better than stainless. In most applications, those differences are small enough not to matter for practical purposes. For example, both knives and guns are made with blued steel and stainless steel. Which a person gets is usually a matter of preference (unless you're, say, a professional restaurant chef whose knives have to hold a fine edge through constant hard use).

- Q: What are the common methods of slitting or shearing steel coils?

- There are several common methods for cutting or shearing steel coils, including: 1. Rotary Shearing: To cut through the steel coil, a rotary shear machine is used. This machine has a set of rotating blades that move in a circular motion, slicing the coil into individual strips of the desired width. 2. Scissor Shearing: Another method involves using scissor-like blades to make the cuts. These blades are typically operated by hydraulic or mechanical systems, exerting pressure on the coil to cut through it. 3. Slitting: This method is commonly used to cut steel coils into narrower strips. The coil is passed through a set of circular blades, known as slitters, which are set at specific distances apart. The slitters cut through the coil, creating multiple strips of the desired width. 4. Guillotine Shearing: For thicker steel coils, a large guillotine machine is used. This machine has a long blade that moves vertically to shear the coil. Guillotine shearing produces clean and straight cuts. 5. Laser Cutting: Laser cutting is an advanced method that utilizes a high-powered laser beam. This beam is directed by computer-controlled systems, allowing for precise and accurate cutting. Laser cutting is often used for complex shapes or when high precision is required. Each of these methods has its own advantages and is suitable for different applications. The thickness of the steel coil, desired strip width, and required level of precision are factors that determine the most appropriate method to use.

Send your message to us

Prepainted galvanized Rolled Steel Coil -CGLCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords