Clad Aluminum Coil - Wooden Grain Pre-painted Aluminum with Good Price and Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Wooden Pattern Coated Aluminum Coil /Anodized Aluminum Coil:

Our PVDF coated color aluminum coil is made of high-performance aluminum sheet and PVDF coating through advanced roller coating process.PVDF coated aluminum coil is a favorably choice of material for high-quality aluminum curtain wall, aluminum veneer sheet, Honeycomb panel. Its products are widely used in airports, convention centers, hotels and other high-end architectural curtain wall decoration

Main Features of Wooden Pattern Coated Aluminum Coil /Anodized Aluminum Coil :

1) Wear resistance 2) impact resistance 3) highly tensile strength 4) easy fabricating 5) UV resistance 6) weather resistance 7) corrosion- resistance 8) various colors.

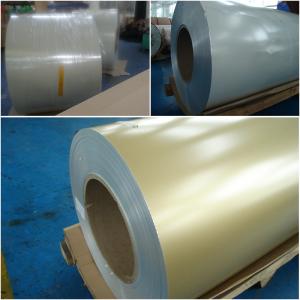

Images of Wooden Pattern Coated Aluminum Coil /Anodized Aluminum Coil:

Wooden Pattern Coated Aluminum Coil /Anodized Aluminum Coil Specification:

| Aluminium series | Alloy | Temper | Thickness | Width | Pattern | Usage |

| 1000 series | 1050/1060/1070/1100 | H0-H112 | 0.3mm-5.0mm | 300mm-2200mm | Sheet/Coil | Chemical equipment, food industry equipment |

2000 series | 2014/2017/2024 | O,T3,T4 | 100mm-1250mm | Sheet/Coil | General Mechanical Components | |

| 3000 series | 3003/3004/3005/3105 | O/H32/H34/H36/H38/H116 | 0.2mm-6mm | 400mm-2000mm | Sheet/Coil | Building, PP cap material |

| 5000 series | 5005/5052/5083/5086/5182/5754 | O/H32/H34/H36/H38/H116 | 0.12mm-10mm | 20mm-2000mm | Sheet/Coil | Architectural decorative pieces, conductor, cookware |

| 6000 series | 6061/6205/6009/6010 | O/T4/T6 | 0.6mm-5mm | 100mm-1800mm | Sheet/Coil | Industrial structures, ships, trams, furniture components |

| 7000 series | 7038/7050/7075 | O/T6/T76 | 0.1mm-3.0mm | 400mm-2000mm | Sheet/Coil | Refrigerated containers, cryogenic equipment and storage tanks |

Test Reports of Wooden Pattern Coated Aluminum Coil /Anodized Aluminum Coil :

| PE | PVDF | |||||||

| Chromatism(ΔE) | Ceiling Decoration | Engineer Ceiling | Primer Print | Back Print | Ceiling Decoration | Engineer Ceiling | ||

| ≤0.5 | ≤0.7 | ≤0.8 | ≤2.0 | ≤0.5 | ≤0.7 | |||

| Pencil Hardness | ≥HB (No Crack or peel off) | |||||||

| Adhensive Resistance | Grade 0;No crack or peel off after the circling&pasting | Grade 0;No crack or peel off after the circling&pasting | ||||||

| Impact Resistance | ≥0.5mm | 0.3-0.5mm | ≥0.5mm | 0.3-0.5mm | ||||

| 50kgs.cm | 20kgs.cm | 50kgs.cm | 20kgs.cm | |||||

| Boiling Water Resistance | no changes by circling after 2h boiling | no changes by circling after 2h boiling | ||||||

| T-Bend Flexibility | composite panel | Ceiling Decoration | Engineer Ceiling | Primer/Back Print | Composite Panel | Ceiling Curtain | ||

| ≤2T | ≤1T | ≤2T | ≤3T | ≤2T | ≤2T | |||

| Coating Thickness(μm) | Topcoat | Primer coating | Double printing | Back Print | Topcoat | Back Print | total coating thickness | |

| ≥16 | 9~11 | 25~28 | 9~12 | 18-20 | 9~11 | 25-28 | ||

| Solvent Resistent | Single print≥100 times | Double print≥200 times | Back Print:30-70 times | Back Print:30-70 times | ≥200 times | |||

FAQ of Wooden Pattern Coated Aluminum Coil /Anodized Aluminum Coil:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

"Aluminum roll rolling machine after rolling, corner after processing, metal products for flying shears.Silicon have a corrosion effect on carbide.Although generally called more than 12% Si aluminum alloy high silicon aluminum alloy, it is recommended to use diamond tool, but this is not absolute, increasing silicon content on the destructive force of the cutting tool is gradually increasing.So some vendors in silica content more than 8% when diamond tool is recommended.Silicon content is between 8% and 12% of aluminium alloy is a transitional zone, can use ordinary carbide, also can use diamond tool.But using carbide method should be used by the PVD (physical coating), excluding aluminum, membrane thickness smaller tool.Because of PVD method and the small film thickness cutting tool to keep the sharp cutting edges, made possible by the (or grew up in order to avoid abnormal film layer on the edge need to enough passivation of blade, cutting aluminum alloy will not sharp), and membrane material containing aluminum may make the blade film layer with the workpiece materials close cooperation with the combination of film and cutting tool substrate.

"

- Q: Is it possible to use a crowbar as a tool for opening an aluminum coil?

- <p>While a crowbar can be used to apply force to open various objects, it may not be the most suitable tool for opening an aluminum coil. Aluminum coils can be sharp and using a crowbar could lead to injury or damage to the coil. It's recommended to use gloves and a pair of pliers or a coil cutter specifically designed for handling aluminum coils to ensure safety and avoid damaging the material.</p>

- Q: How are aluminum coils protected against scratching and abrasion?

- Aluminum coils are protected against scratching and abrasion through various methods and coatings. One common method is the application of a protective film or coating on the surface of the coils. This film acts as a barrier, shielding the aluminum from external forces that could cause scratching or abrasion. Additionally, aluminum coils can undergo a process known as anodizing. Anodizing is an electrochemical method that creates a protective layer on the surface of the aluminum. This layer not only enhances the coil's resistance to scratching and abrasion but also provides it with increased durability and corrosion resistance. Another technique used to protect aluminum coils is the application of a protective lacquer or paint. This coating not only enhances the visual appearance of the coils but also acts as a barrier against potential scratches or abrasion. These protective coatings can be customized to meet specific requirements, such as UV resistance or chemical resistance. Furthermore, aluminum coils can be manufactured with a textured or patterned surface. This texturing creates a more robust surface that is less prone to scratching or abrasion. The texture helps distribute external forces more evenly, reducing the likelihood of damage. Overall, a combination of protective films, anodizing, protective coatings, and textured surfaces are employed to safeguard aluminum coils against scratching and abrasion, ensuring their longevity and performance in various applications.

- Q: Are there any limitations on the bending or shaping of aluminum coils?

- Yes, there are limitations on the bending or shaping of aluminum coils. Aluminum is a relatively soft and malleable metal, which makes it suitable for bending and shaping. However, it does have some limitations. Firstly, the thickness of the aluminum coil can affect its bendability. Thicker aluminum coils are generally more difficult to bend or shape compared to thinner ones. This is due to the increased resistance to deformation in thicker materials. Secondly, the temper or hardness of the aluminum coil can also impact its bendability. Different tempers, such as soft, half-hard, or hard, have varying degrees of malleability. Soft tempers are easier to bend, while harder tempers require more force and may be prone to cracking or breaking during bending. Additionally, the design and complexity of the desired bend or shape can also impose limitations. Sharp bends or complex shapes may cause the aluminum coil to crack or deform, especially if it is not properly supported or if the bending radius is too small. Lastly, the presence of any impurities, defects, or alloying elements in the aluminum coil can affect its bendability. These factors can lead to inconsistencies in the material's mechanical properties, making it more prone to cracking or breaking during bending or shaping. Therefore, while aluminum coils offer flexibility for bending and shaping, it is important to consider the thickness, temper, design, and quality of the material to ensure successful and safe manipulation.

- Q: What is the maximum yield strength of aluminum coils?

- The specific alloy and temper of aluminum significantly influence the maximum yield strength of aluminum coils. Typically, aluminum coils exhibit a yield strength between 10,000 and 40,000 psi. It must be emphasized that diverse properties and, consequently, varying maximum yield strengths are observed in different aluminum alloys and tempers. Furthermore, the thickness and width of aluminum coils have an impact on their maximum yield strength as well. Thus, to ascertain the precise maximum yield strength of aluminum coils, it is advisable to refer to the manufacturer's specifications or standards pertaining to the specific alloy and temper of the coils.

- Q: Can aluminum coils be used in the production of aluminum louvers?

- Yes, aluminum coils can be used in the production of aluminum louvers. Aluminum coils are typically used as a raw material in various manufacturing processes, including the production of aluminum louvers. They can be easily formed and shaped into the desired louver design, offering durability and corrosion resistance.

- Q: How are aluminum coils used in the production of HVAC components?

- Aluminum coils are used in the production of HVAC components as they serve as the heat transfer medium. These coils help in the efficient exchange of heat between the refrigerant and the surrounding air, facilitating the cooling or heating process. The aluminum material is lightweight, durable, and has excellent thermal conductivity, making it ideal for this purpose.

- Q: This question asks for methods to protect aluminum coils from damage during storage and transportation.

- <p>To prevent damage to your aluminum coil during storage or transportation, follow these guidelines: Store the coils in a dry and clean environment to prevent moisture and dirt accumulation. Ensure that the storage area is well-ventilated to avoid condensation. Use appropriate padding or separators between coils to prevent scratching or denting. Handle the coils with care, using proper lifting equipment to avoid dropping or mishandling. Secure the coils during transportation to prevent movement that could lead to damage. Keep the coils away from corrosive substances and extreme temperatures. Regularly inspect the coils for any signs of damage and address any issues promptly.</p>

- Q: Can aluminum coils be used in the production of aircraft fuel tanks?

- Aluminum coils, with their lightweight and durable nature, find application in the creation of aircraft fuel tanks. They are commonly employed in the aerospace industry due to their impressive strength-to-weight ratio. Furthermore, their corrosion-resistant properties make them an ideal choice for fuel tanks, as they can withstand the harsh conditions and chemicals present in aviation fuel. The utilization of aluminum coils enables efficient manufacturing processes, as they can be easily shaped and welded into the desired tank form. Moreover, aluminum possesses excellent thermal conductivity, aiding in the dissipation of heat generated during flight and preventing fuel overheating. In conclusion, aluminum coils are a fitting and extensively utilized material in the production of aircraft fuel tanks.

- Q: Are aluminum coils available in different colors?

- Aluminum coils come in various colors, offering a plethora of design and aesthetic possibilities for different applications. To achieve these colors, the surface of the aluminum coils is coated with a long-lasting finish, which can be found in different hues. This coating process, known as coil coating, involves thoroughly cleaning and pre-treating the aluminum coils before applying a layer of paint or other colored material. Consequently, a wide array of colors can be applied to the aluminum coils, allowing for flexibility in design and aesthetic preferences.

- Q: Are aluminum coils suitable for architectural louvers?

- Yes, aluminum coils are suitable for architectural louvers due to their lightweight nature, durability, and corrosion resistance. They can be easily shaped and formed into various louver designs, providing both functionality and aesthetic appeal to architectural structures.

Send your message to us

Clad Aluminum Coil - Wooden Grain Pre-painted Aluminum with Good Price and Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords