Vinyl Coated Aluminum Coil Stock - PVDF Solid Coated Aluminum Coils for Lids and Tabs with Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of PVDF Solid Coated Aluminium Coils Used for Lids and Tabs with Good Quality

We have different colors for PVDF coated aluminum coils used for lids and tabs of beverage cans. RAL numbers are standard. We also can adjust coating according to color of customers and offer personalized services.

We professionally produce aluminium coated strips used for can tabs or ring-pulls. During production, we use large wave shear, transverse shear and longitudinal cut system so as to meet different specifications of customers.

Based on ordinary aluminum, we add Mn and Mg, so as to increase tensile strength and elongation. Normally we use 5182, H48 for production.

2. Main Features of PVDF Solid Coated Aluminium Coils Used for Lids and Tabs with Good Quality

• Light Weight

• Good in strength and rigidity

• High Flatness

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rust proof

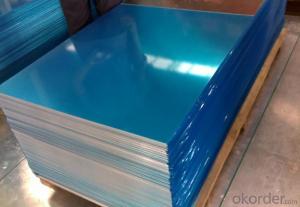

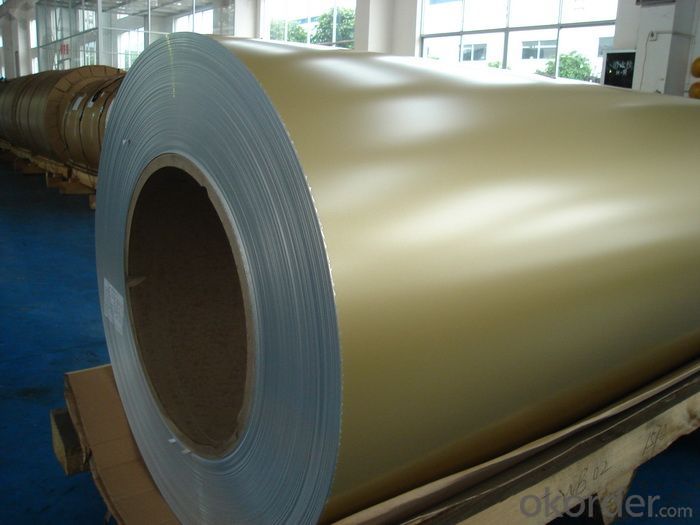

3. PVDF Solid Coated Aluminium Coils Used for Lids and Tabs with Good Quality Images

4. Specification of PVDF Solid Coated Aluminium Coils Used for Lids and Tabs with Good Quality

ALLOY | TEMPER | THICKNESS | WIDTH | COATING and COLOR |

3003, 3105, etc | H44, etc | 0.2-0.6mm | Less than1600mm | AS PER YOUR REQUIREMENTS |

5. FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: Can aluminum coils be used in the production of kitchen utensils?

- Yes, aluminum coils can be used in the production of kitchen utensils. Aluminum is a popular choice for kitchen utensils due to its lightweight, durable, and heat-conducting properties. Aluminum coils can be easily shaped and molded into various utensil designs such as pots, pans, baking trays, and even cutlery. Additionally, aluminum is resistant to corrosion, making it suitable for contact with food and liquids. It is important to note that aluminum utensils may require a non-stick coating or a protective layer to prevent the reaction between aluminum and certain acidic or alkaline foods. Overall, aluminum coils are widely used in the production of kitchen utensils due to their versatility and practicality.

- Q: How are aluminum coils cut and shaped?

- Various methods and tools are utilized to cut and shape aluminum coils, depending on the desired size and shape. Slitting, shearing, and laser cutting are the most commonly employed techniques. Slitting is the act of dividing a wide coil into narrower strips. This procedure entails passing the coil through a series of circular blades that make precise cuts along its length. Thin aluminum strips are typically produced using this method, which can then be further processed or utilized in various applications. Shearing is another popular approach for cutting aluminum coils. It involves the use of a machine with a moving blade to slice through the coil. By applying pressure to the coil, a clean and straight cut is achieved. Shearing is commonly employed for cutting thicker aluminum coils and is ideal for creating straight cuts without deformations. Laser cutting is a more advanced technique used to cut and shape aluminum coils. It employs a high-powered laser beam to either melt or vaporize the metal along a predetermined path. This method offers exceptional precision and enables the creation of complex shapes and designs on the aluminum. Laser cutting is widely used in industries that require intricate and detailed cuts. Following the cutting process, various methods such as bending, rolling, stamping, or forming can be employed to further shape the aluminum coils. These techniques allow for the creation of different geometries and forms based on the specific requirements of the intended application. Overall, the cutting and shaping of aluminum coils involve a variety of techniques and tools, each suitable for different requirements. The choice of method depends on factors such as the coil's thickness, desired shape, and the level of precision necessary for the final product.

- Q: What are the rules and regulations regarding the use of aluminum coil in commercial kitchen settings?

- <p>Yes, there are regulations on the use of aluminum coil in commercial kitchens. These regulations often relate to food safety, hygiene, and the material's suitability for contact with food. Aluminum is generally safe for food contact, but it must meet specific standards to ensure it does not leach harmful substances into food. Regulations may vary by country or region, with some areas having strict guidelines on the types of aluminum alloys allowed and their intended use. Compliance with these regulations is crucial to avoid health risks and legal penalties. It's important for commercial kitchens to use food-grade aluminum and to follow local health department guidelines.</p>

- Q: I was wondering if you could mold clay into a sphere then fill it with aluminum. Then put it over a fire and wait until the aluminum melts then put it in a freezer and it would come out as a sturdy, aluminum sphere. Thanks!

- Do not try this at home! Seriously, this is exactly the kind of process that is used for casting metals. However, you need to have very strong molds with no cracks in them. Also, aluminum presents special problems. Solid aluminum does not corrode the way iron does, because it very quickly forms a protective tough layer of aluminum oxide. But molten aluminum can catch fire, with devastating consequences.

- Q: What advantages does 0.1*100cm aluminum coil have? Is it suitable for the roof tiling? How is the anti-oxidation and anti-corrosion performance?

- 0.1 aluminum sheet has no intensity, so 0.5-1mm colored steel is often used to make roofing.

- Q: What are the methods to prevent rust formation on steel coils during storage and transportation?

- <p>To prevent rust on steel coils during storage and transportation, follow these steps: 1. Keep the coils dry and avoid exposure to moisture. 2. Use rust inhibitors or anti-corrosion coatings on the coils. 3. Store the coils in a clean, dry, and well-ventilated area. 4. Use protective wrapping materials like plastic film or corrosion-resistant paper. 5. Ensure proper stacking and avoid direct contact between coils. 6. Use rust-resistant materials for transportation containers. 7. Regularly inspect the coils for signs of rust and address any issues promptly. By implementing these measures, you can significantly reduce the risk of rust formation on steel coils.</p>

- Q: How are aluminum coils used in packaging?

- Aluminum coils are widely used in packaging due to their excellent properties and versatility. These coils are usually made from aluminum alloy, known for its lightweight yet strong characteristics. One common application of aluminum coils in packaging is in the production of aluminum cans. The coils are rolled into thin sheets, which are then formed into cans of various shapes and sizes. The lightweight nature of aluminum makes it ideal for manufacturing cans that are easy to transport and handle, reducing overall packaging weight. Aluminum coils are also used in the production of flexible packaging materials such as foils and laminates. These materials are commonly used for packaging food products, pharmaceuticals, and other perishable goods. The flexibility of aluminum allows it to be easily shaped and formed into different packaging formats, ensuring efficient and convenient use. Another important use of aluminum coils in packaging is in the production of closures and bottle caps. Aluminum closures provide an airtight seal, protecting the contents of the package from external factors such as moisture, contaminants, or oxidation. Additionally, aluminum closures can be easily opened and closed, providing convenience to consumers. Furthermore, aluminum coils are employed in the production of blister packs, which are widely used in the pharmaceutical industry. Blister packs consist of a plastic sheet with aluminum foil lamination, creating a barrier against moisture, light, and oxygen. This packaging format ensures the integrity and safety of pharmaceutical products by protecting them from degradation or contamination. In summary, aluminum coils are extensively used in packaging due to their lightweight, strength, and versatility. These coils are transformed into various packaging formats such as cans, flexible foils, closures, and blister packs, providing durability, protection, and convenience to both manufacturers and consumers.

- Q: This question asks about the differences between 3D printed aluminum coils and traditionally manufactured aluminum coils.

- <p>Yes, there are differences between 3D printed and regular aluminum coils. 3D printed aluminum coils are manufactured using additive manufacturing, which allows for complex geometries and customization. They can be produced with less material waste and can be designed for specific applications. Traditionally manufactured aluminum coils, on the other hand, are typically made through processes like rolling, which may not offer the same level of design flexibility. 3D printed coils may have different mechanical properties due to the layer-by-layer manufacturing process, potentially resulting in varying strength and durability. Additionally, 3D printed coils might have a higher cost due to the specialized equipment and materials required for additive manufacturing.</p>

- Q: What are the common coil inner diameters for aluminum coils?

- The common coil inner diameters for aluminum coils typically range from 150mm to 600mm, depending on the specific application and industry requirements.

- Q: How are aluminum coils used in the production of battery enclosures?

- Due to their exceptional properties, aluminum coils find wide application in the manufacturing of battery enclosures. Firstly, aluminum, being a lightweight material, is perfect for creating battery enclosures that are lightweight themselves, a crucial feature for portable devices and electric vehicles where weight reduction is of utmost importance. Moreover, aluminum coils can be easily shaped and sized to accommodate specific battery designs, giving manufacturers the ability to customize the enclosures. This flexibility in shaping also aids in optimizing space utilization and enhancing the overall efficiency of the battery system. Furthermore, aluminum exhibits high resistance to corrosion, a vital characteristic for battery enclosures that are frequently exposed to harsh chemicals and environments. This corrosion resistance ensures the longevity and dependability of the enclosure, safeguarding the battery cells from harm and guaranteeing safe operation. Additionally, aluminum possesses excellent thermal conductivity, enabling efficient dissipation of heat generated during battery charging and discharging. This is crucial in preventing overheating and maintaining the optimal temperature range for optimal battery performance. In conclusion, aluminum coils play a pivotal role in the production of battery enclosures by providing lightweight, customizable, corrosion-resistant, and thermally conductive properties. These properties contribute to the overall efficiency, safety, and durability of battery systems employed in a wide range of applications, including consumer electronics, electric vehicles, and renewable energy storage.

Send your message to us

Vinyl Coated Aluminum Coil Stock - PVDF Solid Coated Aluminum Coils for Lids and Tabs with Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords