Prepainted Aluminum Coil for Lamp Cap Stock 8011 H14

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminium Coils for Lamp Cap Stock 8011 H14

Thickness | 0.1mm-10mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm... |

Width | 20mm-2500mm |

inner diameter | 505mm 508mm 605mm |

Material | 1050,1060,1070,1100,1200,3003,3004,3005,5052,5005,5754,5083 |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38,H111,H112 |

Surface | mill finish |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 15-25 days after receiving L/C or deposit |

Remark | Specific requirement of alloy grade, temper or specification can be discussed at your request |

2. Application of Aluminium Coils for Lamp Cap Stock 8011 H14

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminium Coils for Lamp Cap Stock 8011 H14

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

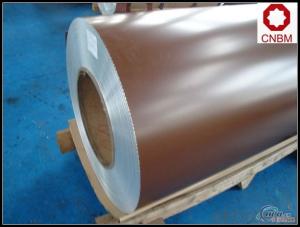

5. Image of Aluminium Coils for Lamp Cap Stock 8011 H14

6. Package and shipping of Aluminium Coils for Lamp Cap Stock 8011 H14

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are aluminum coils suitable for HVAC systems?

- Indeed, HVAC systems can utilize aluminum coils as they prove to be a suitable choice. When compared to conventional copper coils, aluminum coils present numerous advantages. Notably, their heightened resistance to corrosion aids in prolonging the lifespan of the HVAC system. Moreover, aluminum coils possess superior heat transfer properties, facilitating more efficient cooling and heating processes. Additionally, their lighter weight allows for effortless installation and manageable handling during maintenance or repairs. Consequently, aluminum coils emerge as a dependable and cost-effective alternative for HVAC systems.

- Q: Related technical standards of aluminium coil

- GB/T 10456-1989 anodized aluminium foilGB/T 9734-1988 chemical reagent -- General method for the determination of aluminiumGeneral specification for GB/T 9538-1988 strip cable connectorsComplexometric titration fluoride release method for the determination of three aluminium oxide content in GB/T 9489.4-1988 corundum powder twoGB/T 9438-1999 aluminium alloy castingsGB/T 8733-2000 cast aluminium alloy ingotsGB/T 6454-1986 getter aluminium zirconium alloy rings and sheets

- Q: What is the cost of aluminum coils?

- The pricing of aluminum coils can fluctuate based on several factors, including the coil's thickness, width, and length, as well as the prevailing market conditions and supplier. Typically, the cost of aluminum coils is determined by the ongoing market value of aluminum, which is influenced by various aspects such as supply and demand, production expenses, and global economic circumstances. To acquire precise and current pricing details for aluminum coils, it is recommended to reach out to suppliers or consult online platforms.

- Q: what is aircraft grade aluminum?

- Aircraft grade Aluminum is made to be very durable and strong, also Aluminum does not rust.

- Q: Are aluminum coils suitable for construction purposes?

- <p>Yes, aluminum coils can be used for construction. They are valued for their lightweight, corrosion resistance, and high strength-to-weight ratio, making them ideal for applications such as roofing, facades, and structural components. Aluminum's malleability allows for easy shaping and forming, which is beneficial in various construction projects. It's also sustainable due to its recyclability, reducing environmental impact.</p>

- Q: Can aluminum coils be used for heat transfer applications?

- Yes, aluminum coils can be used for heat transfer applications due to their excellent thermal conductivity properties.

- Q: How do aluminum coils perform in cryogenic environments?

- Aluminum coils generally perform well in cryogenic environments due to their low thermal expansion coefficient and high thermal conductivity. When exposed to extremely low temperatures, aluminum coils exhibit minimal contraction and expansion, making them suitable for use in cryogenic applications. The low thermal expansion coefficient ensures that the coils maintain their structural integrity and do not deform or crack under extreme temperature fluctuations. Additionally, aluminum's high thermal conductivity allows for efficient heat transfer, enabling the coils to dissipate excess heat and maintain a stable temperature within the cryogenic environment. Overall, aluminum coils are a reliable choice for use in cryogenic environments and can effectively withstand the challenges posed by extremely low temperatures.

- Q: Are aluminum coils suitable for interior decorative applications?

- Indeed, interior decorative applications are well-suited for aluminum coils. This material, being lightweight and flexible, lends itself to effortless shaping into diverse forms, thus making it perfect for decorative purposes. Moreover, aluminum offers a vast array of finishes, colors, and patterns, granting limitless design options. In addition, its remarkable durability and corrosion resistance guarantee its enduring aesthetic appeal. Furthermore, aluminum is an environmentally friendly choice, as it can be recycled indefinitely, making it a sustainable material for interior decorations. All in all, aluminum coils offer a cost-effective and visually appealing alternative for interior decorative applications.

- Q: Are aluminum coils suitable for roofing?

- Yes, aluminum coils are indeed suitable for roofing. Aluminum is a highly durable and lightweight material that has been widely used in the construction industry for roofing purposes. It offers numerous benefits such as being resistant to rust, corrosion, and fire, making it an ideal choice for areas with harsh weather conditions or high humidity. Aluminum coils are also known for their excellent thermal conductivity, which helps in reflecting sunlight and reducing energy consumption, leading to lower cooling costs. Additionally, aluminum roofing is easy to install and maintain, providing long-lasting protection for residential, commercial, and industrial buildings.

- Q: Explain the differences between aluminum coils and iron coils, including their properties and applications.

- <p>Aluminum coils and iron coils differ in material composition, weight, strength, and applications. Aluminum coils are made of aluminum, a lightweight, corrosion-resistant metal, while iron coils are made from iron, which is heavier and more prone to rust. Aluminum coils have a lower density, making them ideal for applications where weight is a concern, such as in construction or automotive industries. They also have excellent electrical and thermal conductivity. Iron coils, on the other hand, are stronger and more durable, making them suitable for heavy-duty applications like construction reinforcement and machinery parts. Iron is also magnetic, which is an advantage in certain applications. However, iron is more susceptible to corrosion and requires protective coatings or treatments to extend its lifespan.</p>

Send your message to us

Prepainted Aluminum Coil for Lamp Cap Stock 8011 H14

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords