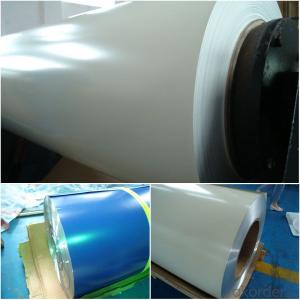

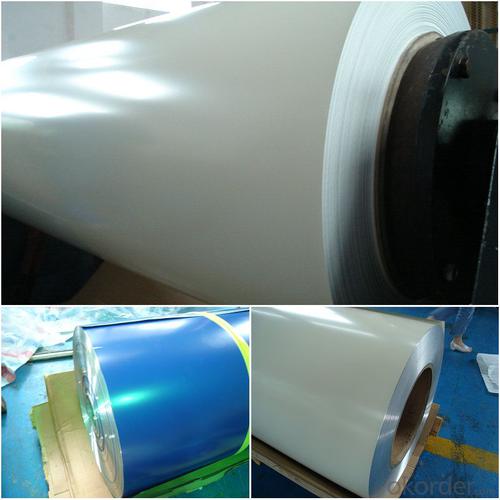

Aluminum Sheet Coil Houston - Prepainted Aluminum Coating Roll Metals PVDF Coating

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Color coated aluminum coil isa material with excellent acid-resistance and alkali-resistance. The coating layeris even with bright color to last for a very long time. It is a greendecoration material with the characters of environment protection,flame-resistance, and groovy colors. In nowadays, the color coatedaluminum coil has become the popular material for top grade decoration. With our advance professional aluminum coated technique, wecan custom various aluminum coils ,like coated aluminum coil , Color coatedaluminum coil , embossed aluminum sheet with the color and size which youdemands.

1)Process: pre-treatment, continuous painting and baking for times .

2)Material: high quality material, aluminum sheets from South West AluminumIndustry Company in China, pre-treatment material from Henkel & Chemtellfrom Germany, more than 70% of PVDF coating from PPG Corp., the USA andpolyester from Sweden Becker Industrial Coating Co., Ltd.

3) Ourproducts can keep excellent quality and stability.

4)Thickness: 0.06 - 1.0mm; width: 20 - 1,590mm

Applications:

The aluminum coils are widely used in ACP/curtainpanel/honey comb panel/shutter/roofing and most of the decoration areas. Withthe superior quality and advanced management, our products had been export toEuro/North America /East Asia and many other areas and countries.

PEAluminum Coating Coils for ACP

Featuresof PE Aluminum Sheet:

1.Adopting precision rolling coating technology, our PVDF and PE coated coil canensure excellent adhesive without coating omission.

2. For thePE coated aluminum coil we produced, there are various colors for your choice.

3. Usinginfrared heating technology to protect environment from pollution.

4. Ourcoated aluminum coil has four-roller coating line, uniform coating thicknessand good features.

RawMaterial of the PE Aluminum Coating Coils:

1. Aluminum Coil: high strength aluminum withalloy of AA1100 (aluminum alloy is available with AA3003, AA3005, AA5005according to customer)

2. Surface Paint: PE, PVDF and specialpaints.

Specification of PE Aluminum Coating Coil

Width: 20mm~1590mm

Thickness: 0.06mm~1.0mm

External Diameter: ≤ 1500mm

Internal Diameter: 405mm, 505mm, 150mm, 75mm

Coil weight: ≤ 4000kg

PE coated aluminum coil is processed throughthe technics of roller coating and baking with precise polyester paints. Itscolor is glossy and with variety of colors enabling you to choose easily.Chromatic aberration is small, impact resistance is strong and easy to beprocessed, and all its performance has reached or surpassed the nationalcriteria. The products are widely used in indoor and door decoration, ceilings,room surface tiles, corrugated boards, wallpanels, advertisement boards, counters, home appliances, decoration in and outof autos and boats.

Performance of thecoating

Aluminum Thickness | Coating Thickness | MEK | T- Bend | Impact | Adhesion | Pencil Hardness | Boiling Water Proof |

0.3-1.5mm | ≥18μm | ≥100 Times | ≤2T | 50 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.2-0.28mm | ≥18μm | ≥100 Times | ≤2T | 30kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.15-0.18mm | ≥18μm | ≥100 Times | ≤3T | 20 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.08-0.12mm | ≥16μm | ≥80 Times | ≤4T | 10 kg•cm | ≤1 Grade | ≥HB | no change within 1 hour |

0.022-0.06mm | ≥12μm | ≥50 Times | - | - | ≤1Grade | ≥HB | no change within1 hour |

Color of Card

PE (polyester)

PE

Color Match

For custom' color requests, we can deal as following:

1. Supply a physical sample of custom color. A color sample on metal ispreferred. If other, it is also acceptable. But the color matching rate may benot good as color on metal.

2. New color sample is usually offered by our paint supplier in 5-7 days,special color should be in 7-10 days.

3. Upon receipt of color sample, please approve in writing as soon as possible.Once you approved, we will arrange purchasing and production.

Note: Color difference maybe occurred in different production batch, so it issuggested all panels are placed in one order for same project. And keep samedirection as arrow on protective film when installing to avoid any colordifference by vision

- Q: What are the potential applications of coil-perforated aluminum coils?

- Coil-perforated aluminum coils have a wide range of potential applications due to their unique properties and capabilities. Some of the potential applications of these coils are: 1. Architectural Applications: Coil-perforated aluminum coils can be used in architectural projects for facades, cladding, and sunscreens. The perforations allow for the creation of decorative patterns and designs, while also providing functional benefits such as ventilation and light control. 2. Industrial Applications: These coils can be used in various industrial applications such as filtration systems, soundproofing panels, and heat exchangers. The perforations in the aluminum coils allow for the passage of air, sound, and heat, making them suitable for these purposes. 3. Automotive Industry: Coil-perforated aluminum coils can be utilized in the automotive industry for applications such as radiator grilles, speaker covers, and air vents. The perforations in the coils provide functional benefits like airflow, sound transmission, and aesthetic appeal. 4. HVAC Systems: These coils can be employed in heating, ventilation, and air conditioning (HVAC) systems. The perforations in the aluminum coils allow for improved airflow, which helps in efficient temperature regulation and air distribution within buildings. 5. Acoustic Panels: Coil-perforated aluminum coils can be used in the construction of acoustic panels, which are designed to absorb and reduce sound reflections in spaces like auditoriums, theaters, and recording studios. The perforations in the coils aid in sound absorption and diffusion. 6. Lighting Fixtures: These coils can be incorporated into lighting fixtures to create unique lighting effects. The perforations in the aluminum coils allow light to pass through, resulting in visually appealing patterns and designs. 7. Furniture and Decorative Applications: Coil-perforated aluminum coils can be utilized in the manufacturing of furniture, screens, partitions, and decorative elements. The perforations in the coils add a distinctive aesthetic appeal and can create interesting visual effects. Overall, the potential applications of coil-perforated aluminum coils are diverse and encompass various industries, including architecture, automotive, industrial, HVAC, acoustic, lighting, and furniture. The unique properties of these coils, such as their lightweight, durability, and aesthetic customization options, make them a versatile choice for many different uses.

- Q: What is the maximum coil weight for aluminum coils?

- The maximum coil weight for aluminum coils can vary depending on various factors such as the thickness and width of the coil, as well as the specific alloy being used. Generally, the maximum coil weight for aluminum coils ranges from around 5,000 to 25,000 pounds. However, it is important to note that these figures are approximate and can differ depending on the manufacturer's guidelines and equipment capabilities. Additionally, it is always recommended to consult the manufacturer or supplier for specific coil weight limitations to ensure safe handling and transportation.

- Q: Can aluminum coils be used in electrical transformers?

- Yes, aluminum coils can be used in electrical transformers. While copper is the most commonly used material for transformer windings, aluminum has also been increasingly used due to its cost-effectiveness and lighter weight. Aluminum coils are typically used in distribution transformers, which are smaller in size and operate at lower voltages. However, there are certain considerations to bear in mind when using aluminum coils in transformers. Aluminum has a lower conductivity than copper, so the aluminum coils need to have larger cross-sectional areas to compensate for this. Additionally, aluminum has a higher coefficient of thermal expansion than copper, so proper precautions must be taken to account for the differential thermal expansion between the aluminum windings and other transformer components. Overall, aluminum coils can be a suitable choice for specific transformer applications, but the design and manufacturing process must be carefully executed to ensure optimal performance and reliability.

- Q: Can aluminum coils be used in electrical applications?

- Yes, aluminum coils can be used in electrical applications. Aluminum is often used as a conductor in electrical wiring due to its high conductivity and low cost compared to copper. Aluminum coils are commonly used in transformers, motors, generators, and other electrical equipment. However, it is important to note that aluminum has a lower electrical conductivity than copper, so larger aluminum coils may be required to achieve the same level of conductivity. Additionally, aluminum coils may require special insulation and connectors to prevent corrosion and ensure proper electrical connections.

- Q: What are the common sizes of aluminum coils?

- The common sizes of aluminum coils can vary depending on the specific industry and application. However, some commonly used sizes include widths ranging from 36 inches to 72 inches, with thicknesses typically ranging from 0.019 inches to 0.125 inches.

- Q: How are aluminum coils protected against scratching and abrasion?

- Various methods and coatings are utilized to protect aluminum coils from scratching and abrasion. One commonly employed technique involves applying a protective film or coating to the coils' surface. This film acts as a barrier, shielding the aluminum from external forces that may lead to scratching or abrasion. In addition, aluminum coils can undergo an electrochemical process called anodizing, which generates a protective layer on the aluminum's surface. This layer not only increases the coil's resistance to scratching and abrasion but also enhances its durability and corrosion resistance. Protective lacquer or paint can also be applied to aluminum coils to safeguard them. This coating not only enhances the coils' visual appearance but also acts as a barrier against potential scratches or abrasion. These protective coatings can be customized to meet specific requirements, such as UV resistance or chemical resistance. Furthermore, aluminum coils can be manufactured with a textured or patterned surface, which creates a more robust surface that is less susceptible to scratching or abrasion. The texture helps distribute external forces more evenly, reducing the chances of damage. Overall, a combination of protective films, anodizing, protective coatings, and textured surfaces is employed to ensure the longevity and performance of aluminum coils in various applications while safeguarding them against scratching and abrasion.

- Q: WHERE IS ALUMINIUM FOUND, LIKE WHERE IS IT MINED FROM...10 points tell me quick

- Australia, Brazil, China, India

- Q: This question asks for the method to calculate the volume of an aluminum coil given its size.

- <p>To calculate the volume of an aluminum coil, you need to know its dimensions: the length of the coil, the diameter of the wire, and the number of turns. The volume can be calculated using the formula for the volume of a cylinder, adjusted for the coil's shape. The formula is: Volume = 蟺 * (diameter/2)^2 * length * number of turns. Here, 蟺 is approximately 3.14159, diameter is the diameter of the wire in the coil, length is the total length of the coil, and the number of turns is the number of times the wire is wound around the coil. This formula gives you the total volume of the aluminum in the coil.</p>

- Q: Can aluminum coils be used in wastewater treatment plants?

- Indeed, wastewater treatment plants can utilize aluminum coils. These coils are frequently employed in the fabrication of heat exchangers, which play a crucial role in wastewater treatment plants. Heat exchangers function by transferring heat from the wastewater to the treatment procedure, thereby enhancing treatment efficiency and minimizing energy usage. Aluminum coils are favored in certain situations due to their exceptional thermal conductivity, lightweight nature, and resistance to corrosion. These characteristics render them suitable for the demanding conditions found in wastewater treatment plants. Furthermore, aluminum coils are cost-efficient and possess a prolonged lifespan, thus establishing them as a dependable option for implementation in wastewater treatment facilities.

- Q: What are the potential risks of using aluminum coils in specific applications?

- The potential risks of using aluminum coils in specific applications include corrosion, especially in environments with high humidity or acidic conditions. Aluminum coils are also more susceptible to damage and denting compared to other materials. Additionally, aluminum coils may have lower heat transfer capabilities, which could affect the efficiency of certain applications.

Send your message to us

Aluminum Sheet Coil Houston - Prepainted Aluminum Coating Roll Metals PVDF Coating

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords