Prepaintd galvanized steel coils Any color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Standard sea worthy export packing with reinforce |

| Delivery Detail: | 15 days after receiving the advance payment |

Specifications

Thickness:0.12-2.0mm

width:650-1250mm

Zinc coating:40-200g/m2

Certificates:ISO9001:2000, SGS, SONCAP

Standard: ASTM,JIS,GB

Brief introduction:

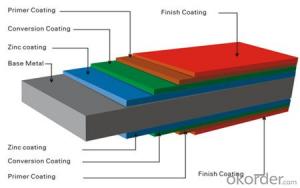

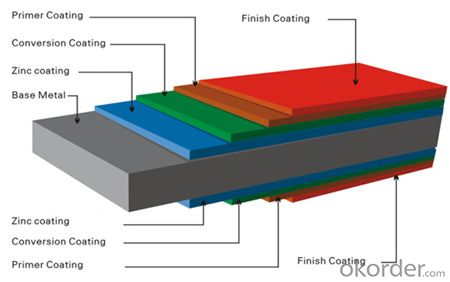

Galvanized steel coils are produced through a process of metal coating which involves passing cold rolled coils through a zinc pot. The process ensures the adherence of zinc to the surface of steel sheet. The zinc layer provides excellent corrosion resistance so that it can prolong the service life of the product..

Hot dipped galvanized products are widely used in roofing, household appliance, container manufacturing, base material for pre-painting, ducting(pipe) and other construction related appliance.

Color coating steel coils are produced by cold rolled GI steel which is coated with a layer of oil pait.After painted, the coils has beautiful appearance and more durable.

Technical specifications:

| Standards | GB/JIS/ASTM |

| Size range | Thickness:0.15-1.5mm, width:750-1000mm |

| Zinc coating | 40-75g/m2 |

| Coil ID | 508mm |

| Surface | Chromated/Un-oiled/Oiled/Dry |

| Spangle | Regular/Minimized/Big spangle |

| Coil weight | 2-12mt |

| Material | SGCC, DX51D,SGCH |

| Paint | Top side:17-25 micron, back side 5-10 micron |

| Color | RAL Chart, as per customer’ color swatch |

- Q: Is steel harder than iron or is iron harder than steel?Please explain... and help!Thanks

- steel is harder than iron Iron is a chemical element. It is a strong, hard, heavy gray metal. It is found in meteorites. Iron is also found combined in many mineral compounds in the earth's crust. Iron rusts easily and can be magnetized and is strongly attracted to magnets. It is used to make many things such as gates and railings. Iron is also used to make steel, an even harder and tougher metal compound. Steel is formed by treating molten (melted) iron with intense heat and mixing it (alloying) with carbon. Steel is used to make machines, cars, tools, knives, and many other things.

- Q: How does coil slitting work?

- Coil slitting is a process used in metalworking to cut large coils of material, such as steel or aluminum, into narrower strips. It involves feeding the coil through a set of circular knives or rotary slitters that cut the material into desired widths. The slitting process can be adjusted to achieve precise measurements, and the resulting strips are typically rewound onto separate coils or spools. Coil slitting is commonly used in various industries, including automotive, construction, and manufacturing, to obtain narrower strips that can be further processed or used as raw material for different applications.

- Q: That's my question, well that and:Steel Pick + Electric Guitar = Trashed Guitar?:D

- A steel pick + acoustic on nylon strings = not so good A steel pick + acoustic on steel strings = this might work A steel pick on electric guitar = this might work too I don't think you would trash the guitars, and you probably wouldn't have to worry about being electrocuted...lol... A plastic pick would be so much better. Do they even make steel picks ?

- Q: So i downloaded Broken Steel DLC for Fallout 3 for the 360. My guy is on the level where you have to activate the purifier and when i beat it. It was the normal ending that brought me back to the main menu. My friend said you have to find some guy to talk to but i don't think thats it. Please Help. P.S. i never got and conformation in-game about the download but its under the download sub menu at the main menu.

- Try Redownloading BS, That should work.

- Q: What are the common coil loading and unloading techniques?

- Some common coil loading and unloading techniques include using cranes or forklifts to lift and place the coils onto trucks or storage racks, using coil cars or transfer cars to move the coils within a facility, and using coil handling equipment such as coil grabs or C-hooks to safely grip and manipulate the coils during the loading and unloading process.

- Q: days. Use your knowledge of the corrosion of steel and aluminum to predict how they would look different after a week exposed to rainy weather. Explain your prediction.

- Steel rusts, aluminum doesn't so the steel can would be rusty and the aluminum can would not.

- Q: I have to explain some functions of stainless steel but after days of searching I cant find an answer. Thankyou in advance for your help :)

- www.okorder

- Q: How does the steel coil market vary regionally?

- The steel coil market varies regionally based on factors such as demand, production capacity, and market dynamics. Different regions have different levels of industrial development and infrastructure, which can affect the demand for steel coils. Additionally, variations in raw material availability, labor costs, and government policies also contribute to regional differences in the steel coil market. For example, developing regions may have higher demand for steel coils due to infrastructure projects, while mature markets may focus on specialized steel coil products for specific industries. Overall, regional variations in the steel coil market reflect the unique economic and industrial characteristics of each region.

- Q: I have a tiara and it oxidized and I'm not sure what material it is. I know it it isn't metal so i was wondering if is steel? Also if it's steel, can I do something to clean it?

- Yes - Steel can oxidize, its most commonly called rust Steel is a metal. Depending on the level of oxidation, you might be able to polish it with very fine steel wool. If is is really bad, then you might need a chemical cleaner such as Naval Jelly, which can be found at the hardware store. But the Naval Jelly might discolor the metal, so then you might need to polish it afterward to return its finish.

- Q: Are they made using the same processes, or is tempered steel made without the quenching process?

- No. Not quite. The term 'Hardened steel' is often used to refer to 'Heat treated steel'. There are two separate steps in heat treatment. First the red hot steel is 'quenched' (rapidly cooled). This yields maximum hardness ,but the steel may be too brittle for the intended purpose. The next stage, 'tempering' is heating to a limited temperature, and slow cooling. This reduces the hardness somewhat, depending on the re-heat temperature, but restores some of the toughness lost in the first stage.

Send your message to us

Prepaintd galvanized steel coils Any color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords