Pre-painted Galvanized steel Coil of All Size

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Prepainted Galvanized steel Coil

With Gi as base metal, after pretreatmet (degrease and chemical treatment) and liquid dope with several Layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized steel ( PPGI) .Pre-painted galvanized steel is good capable of decoration ,molding, corrosion resistance

2.Main Features of Pre-painted Galvanized steel Coil

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

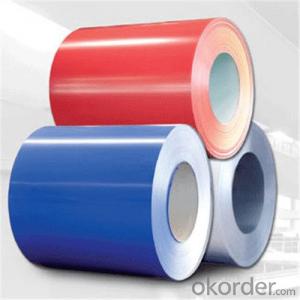

3.Pre-painted Galvanized steel Coil Images

4. Pre-painted Galvanized steel Coil Specification

Standard: ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.5 | 0.900 | 0.039 | 0.010

|

5.FAQ of Prepainted Galvanized steel Coi

We have organized several common questions for our clients,may help you sincerely:

1.how long we will receive the goods ?

After receiving your deposit or workable lc ,our normal shipment date is 15-20days,and it takes around 28 days to reach your port of destination. But is up to different destination

2.How do you control your quality

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Want to construct a patio cover approx. 20 feet long. Only want to use a 6x6 or 8x8 post at each end. What size steel i-beam would I have to use to carry the load???

- Probably the reason some contractors don't like this idea is that your new built-up beam, being only 6 tall, is not going to allow the joists above to attach effectively. The triple microlam with steel plates is sooooooo overkill in strength, but doesn't have the height to allow the floor joists to proberly attach. Your span is not so great that a built-up beam wouldn't work great. Assuming that your second floor joists are 2 x 10, I would use 2- 2 x 10 with 1/2 plywood sandwiched between. This is all that you really need.

- Q: How do steel coils contribute to the manufacturing of household appliances?

- Steel coils contribute to the manufacturing of household appliances by providing a durable and versatile material for various components. These coils are used to create the outer casings, frames, and structural parts of appliances like refrigerators, washing machines, and dishwashers. The strength and flexibility of steel coils ensure the longevity and stability of these appliances, while also enabling manufacturers to create sleek and attractive designs.

- Q: How are steel coils processed for edge conditioning or slitting?

- Steel coils are processed for edge conditioning or slitting through a series of steps. First, the coil is unwound and flattened to remove any bends or curls. Then, the edges of the coil are trimmed or conditioned to ensure a smooth and straight edge. After that, the coil is slit into narrower strips using specialized machinery. This process allows for the production of various widths of steel strips, which can be used for different applications.

- Q: What is the process of uncoiling steel coils?

- The process of uncoiling steel coils involves unwinding the tightly wound steel coils using specialized equipment such as uncoiling machines or decoilers. These machines utilize hydraulic or mechanical systems to hold the coil securely while gradually releasing the tension on the coil. As the coil is released, it starts to unwind, with the steel strip gradually straightening out. This process allows for the easy feeding of the steel strip into further production processes such as cutting, stamping, or forming.

- Q: How are steel coils used in the production of power generation equipment?

- Steel coils are used in the production of power generation equipment as they are shaped and formed into various components such as turbine casings, generator frames, and steam pipes. These coils provide the necessary strength and durability to withstand the high temperatures, pressure, and mechanical stresses involved in power generation processes. Additionally, steel coils are often coated with protective layers to prevent corrosion, ensuring the longevity and reliability of the equipment.

- Q: What are the different methods of coil leveling?

- Various industries commonly utilize several methods for coil leveling. These methods encompass: 1. Roller leveling: By passing the coil through a sequence of rollers, pressure is applied gradually, resulting in the gradual flattening of the coil. The rollers can be adjusted to exert varying levels of pressure, allowing for precise control over the leveling process. 2. Stretch leveling: This technique subjects the coil to tension forces, elongating the material and eliminating internal stresses. As the coil is stretched while passing through rollers, a more uniform and flat surface is achieved. 3. Temper leveling: Involving the heating of the coil to a specific temperature followed by rapid cooling, this method helps equalize stresses within the coil and enhance its flatness. Temper leveling is often employed for high-strength steels. 4. Roller leveling with leveling rolls: This approach utilizes additional leveling rolls placed above and below the main leveling rollers. These rolls apply pressure to specific areas of the coil, rectifying any unevenness or distortions. 5. Tension leveling: This method involves applying tension to the coil during processing. The tension aids in straightening and flattening the material, resulting in a more even and flat surface. 6. Precision leveling: Employed for high-precision applications necessitating extremely flat and uniform coils, precision leveling combines roller leveling, stretch leveling, and other corrective measures to attain the desired flatness. Each of these methods possesses unique advantages and limitations. The selection of a particular method depends on factors such as the type of material being leveled, the required flatness tolerance, and the intended application of the coil.

- Q: How are steel coils used in the production of electrical switches?

- Steel coils are used in the production of electrical switches as they serve as a crucial component in the electromagnet that enables the switch to function. The magnetic properties of the steel coils allow for the creation of a strong magnetic field when an electric current passes through them, which in turn allows the switch to be activated or deactivated, controlling the flow of electricity.

- Q: How are steel coils processed for slitting or edge conditioning?

- Steel coils are typically processed for slitting or edge conditioning through a series of steps. First, the coils are uncoiled and inspected for any defects or damages. They are then leveled and straightened to ensure a uniform thickness and flatness. Next, the steel is fed through a slitting machine, which uses rotating circular blades to cut the coil into narrower strips. These strips can be further processed for edge conditioning, where the edges are trimmed or profiled to meet specific customer requirements. This can be done through various methods such as shearing, deburring, or edge rolling. Overall, the process involves precision cutting and shaping techniques to transform the steel coils into desired slitted or edge-conditioned products.

- Q: Is it possible to make a homemade blacksmith forge from a washing machine drum made of stainless steel?

- Homemade Blacksmith Forge

- Q: I want to get one of these knives but I am having trouble deciding which is the best overall knife??ThanksSOG Trident tigerSOG Vulcan TantoSOG Bi-Polar (Serrated)Cold Steel ScimitarCold Steel Recon 1

- Look up a knife maker called Bench Made, the knife i recommend is the CQC7 its a tanto tip half serrated blade all low glare black folding with pocket clip. it has one of the hardest steel blades. You need to learn about steel hardness the harder the blade the sharper it can get and the harder the longer it will hold a edge. but hard steel can get brittle it can snap now as softer steel will bend and dull quick. the bench-made CQC7 goes for around $100 or that ball park...enjoy read some about the knife and think about what you want it for....my CQC7 can cut a coat hanger by pulling the serrate across the hanger!!

Send your message to us

Pre-painted Galvanized steel Coil of All Size

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords