Pre-Painted Galvanized/Aluzinc Steel Coil with Best Quality in Any Color in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Pre-Painted Galvanized/Aluzinc Steel Coil with Best Quality in Any Color in China

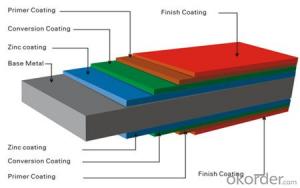

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Technique: Cold Rolled

Width: 20-1250mm

Length: customized

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

coil weight: 4-7 tons

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: What are the main factors that affect the corrosion resistance of steel coils?

- The main factors that affect the corrosion resistance of steel coils include the composition and purity of the steel, the presence of alloying elements, the surface condition and finish of the coils, the exposure to moisture and corrosive substances, and the protective coatings or treatments applied to the steel.

- Q: How are steel coils used in the production of pipelines?

- The production of pipelines relies heavily on steel coils, which are indispensable components. These coils, crafted from top-notch steel, are utilized in the manufacturing of the pipes themselves. To initiate the process, the steel coil is unfurled and then cut into the desired size and length. The resulting pieces are then molded into cylindrical tubes through a technique known as pipe forming. Once the pipes are formed, they undergo several additional procedures to bolster their strength and durability. These may include welding, heat treatment, and coating to safeguard against corrosion. Steel coils are also employed in the creation of essential fittings and connectors required for the connection and joining of the pipes. The utilization of steel coils in pipeline production offers numerous advantages. Firstly, steel possesses exceptional strength and durability, rendering it ideal for withstanding the high pressure and stress that pipelines endure. Additionally, steel exhibits remarkable resistance to corrosion, a critical characteristic for pipelines that transport various substances like oil, gas, or water. Moreover, steel coils facilitate efficient production processes. The uniformity of the coils ensures consistent pipe dimensions, thereby facilitating easy assembly and installation. The versatility of steel allows manufacturers to customize pipes of varying sizes and specifications to meet specific project requirements. In conclusion, steel coils assume a crucial role in pipeline production. They are utilized in the creation of pipes, fittings, and connectors. The utilization of steel guarantees strength, durability, and resistance to corrosion, making it the preferred material for pipelines. Furthermore, steel coils enable efficient production processes and offer versatility in terms of customization.

- Q: I'm doing a commercial for chemistry and I need to know any kind of chemistry dealing with Callaway Big Bertha Irons. I know they are stainless steel but any more info would help out! Thank you! :)

- Stainless steel is a mixture of metals, each metal is included in order to make up for each others weaknesses. Each metal is included due to a property that is benificial in some way, for instance Chromium is included because it makes the stainless steel 'stainless'. In chemistry a mixture of metals, stainless steel, is called an alloy.

- Q: What are the challenges faced during steel coil processing?

- Some of the challenges faced during steel coil processing include ensuring proper alignment and feeding of the coils into the machinery, handling the heavy weight and size of the coils, managing the high temperatures involved in processing, preventing surface defects or damage to the steel, maintaining consistent quality throughout the process, and minimizing material waste and scrap.

- Q: I want to buy a VERY sturdy bunkbed, but don't know which one would be better with not getting loose or falling apart.

- Metal, the screws can loosen, but most of the joints in a metal bed are welded, and screws that work loose are easy to tighten, once a screw or glued joint comes loose in a wood bed it will never be the same. The metal bunkbed my daughter had only needed screws to keep the upper safety rail from wobbling, but without any screws it would still stay together.

- Q: How are steel coils used in the manufacturing of signage?

- Steel coils are used in the manufacturing of signage as they provide a strong and durable base for creating various types of signs. These coils are typically cut, shaped, and welded to form the desired sign structure. The steel material ensures that the signage can withstand outdoor conditions, including extreme weather, while maintaining its structural integrity. Additionally, steel coils can be easily painted or coated to enhance the visual appeal of the signage and protect it from corrosion.

- Q: How are steel coils used in the production of kitchenware?

- Steel coils are used in the production of kitchenware as they are unrolled and cut into specific shapes and sizes to form the base or body of various utensils like pots, pans, and trays. The coils are then shaped, molded, and welded to create the desired kitchenware products, which are further processed for surface finishing, such as polishing or coating, before being ready for use in households or commercial settings.

- Q: I was wondering what kind of company casts and sells steel without acting as a contractor as well. They only sell steel no install it

- If you are talking about raw steel materials and products I believe you are talking about a steel processor and warehouse company or a steel distributor. There are many different points along the steel manufacturing process that you could buy steel products. It would depend on various factors. Depending the amount, type, grade, gauge, properties, origin and a host of other elements you could purchase the steel in billet, plate, diamond plate, rolled sheet (cold or hot), coil, beam, stamped, pickled, scrapped, etc. You get the idea. Now I don't know where you are in the world, but you can go to one of the two sites below, which I have used for product sourcing and research before. The last one is a major manufacturer that I have actually been to. I hope this helps.

- Q: I have a steel string, Yamaha acoustic guitar that I am learning to play at home. But at school I use a rented nylon string guitar. I like the feel of the nylon strings better then the steel strings and i was wondering if i can just switch strings or if i should just get another guitar. Can anyone help?

- No, okorder /... You will want a full size or possibly a 3/4 size guitar. A 3/4 size guitar is a little smaller and will be closer in neck width to a steel string guitar. I used one like that when I started out playing when I was young. Avoid the cheap ones on Amazon that only cost $30-$50.

- Q: How are steel coils used in the agricultural sector?

- Steel coils are used in the agricultural sector for various purposes such as manufacturing machinery, constructing storage facilities, and creating equipment like irrigation systems and grain bins. They provide strength, durability, and flexibility to support the demanding needs of the agriculture industry.

Send your message to us

Pre-Painted Galvanized/Aluzinc Steel Coil with Best Quality in Any Color in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords