Premium Colorful Corrugated GI Galvanized Metal Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Brief Introduction

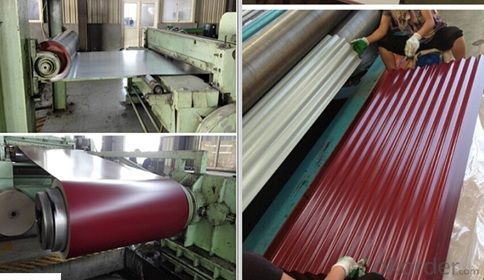

Premium Colorful Corrugated GI Galvanized Metal Sheet

Galvanized Corrugated Steel Roofing Sheet is formed by cold roll machine, using galvanized steel sheet or aluminum steel as the base material .Galvanized corrugated steel roofing sheet is featured with easy installation ,high strength ,more economic .( low cost )

Product Features

.Outlook Beautiful and novel, rich colors, flexible combination, can be used in different buildingto express special original architectural styles in life.

.Surface have been treated as galvanized and color coated.so it can anti-rain,anti- fire,anti-quake,So it has a long term life as 20-30 year and color just not fade.

. Light weight: easy to transport the material,short the time to finish the building,reduce worker's hard work,save much time and energy for human beings.

.Smooth surface treatment,the dust will be easy taken off by the rain.

. Environmental material,can be used many times,will do no hard to the our environment.

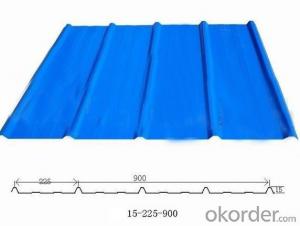

Product Specification

.Thickness:0.13mm to 0.8mm

.Length: 1m to 11.8m.

. Color: navy blue,white grey and any RAL colors.

. Certification: ISO9001:2000.

.Material : cold rolled galvanized steel coil.

. Standard: JIS,DX51D,SGCC,Q235. A653

. advantage: waterproof,light weight, high strength,best price.

. HS code: 7210700000

Packing Information (For 27.5 Tons heavy 20’Fcl)

. water proof paper packing in side

. plastic film Packing in middle

. steel sheet Packing out side

.several steel strip packing to fix the packing

Production Line & Package

FAQ

1. how many wave for per pcs

—— some wave is 8 ,same wave is 9 ,save wave is 11 ,it is up to your request

2. What is the MOQ for this products ?

—— Normally the MOQ is 25mt per size and per color .

- Q: What are the common tolerances for steel strips?

- The common tolerances for steel strips vary depending on the specific application and manufacturing process. However, some common tolerances for steel strips include thickness tolerances ranging from ±0.001 inches to ±0.010 inches, width tolerances ranging from ±0.005 inches to ±0.050 inches, and length tolerances ranging from ±0.010 inches to ±0.100 inches. It is important to note that these tolerances can be further customized based on the specific requirements of the project.

- Q: How are steel strips tested for internal defects?

- Steel strips are tested for internal defects using various non-destructive testing (NDT) methods. One common technique is ultrasonic testing, which involves sending high-frequency sound waves through the steel strip and measuring the time it takes for the waves to bounce back. Any inconsistencies or defects within the material will cause the sound waves to reflect differently, allowing technicians to identify internal flaws such as cracks, voids, or inclusions. Another method used is magnetic particle inspection, which relies on the principle of magnetism. A magnetic field is created around the steel strip, and if there are any defects present, they will disrupt the magnetic field, causing magnetic particles to cluster around the defect. This makes the flaw visible and easily detectable. Eddy current testing is another widely used technique. It involves passing an alternating current through a probe that is placed near the steel strip's surface. Any internal defects will cause a change in the electrical conductivity of the material, which in turn alters the eddy currents flowing within it. This change is detected by the probe, allowing for the identification of internal flaws. Other methods such as radiographic testing, which utilizes X-rays or gamma rays to penetrate the steel strip and produce an image of its internal structure, or dye penetrant inspection, which involves applying a colored liquid dye to the steel's surface and observing if it seeps into any cracks or defects, are also employed depending on the specific requirements and characteristics of the steel strips. These non-destructive testing methods are crucial in ensuring the quality and integrity of steel strips, as they allow for the reliable detection of internal defects without damaging the material. By identifying these flaws early on, manufacturers can take appropriate actions to rectify or remove defective strips, thereby preventing potential failures or accidents in the future.

- Q: Are steel strips used in the production of automotive exhaust systems?

- Indeed, it is a common practice to utilize steel strips in the manufacturing process of automotive exhaust systems. Referred to as steel coils as well, these strips are frequently employed in the production of pipes, tubes, and various exhaust system components. As a result of their exceptional strength, durability, and resistance to heat, they are deemed suitable for enduring the elevated temperatures and corrosive gases generated by the engine. Furthermore, steel strips possess the advantage of being easily molded, welded, and shaped to meet the precise design specifications of the exhaust system. Consequently, they have gained significant popularity within the automotive industry.

- Q: How are steel strips used in the production of automotive fasteners?

- Steel strips are an integral component in the production of automotive fasteners. These strips are typically made from high-quality steel, which offers excellent strength, durability, and corrosion resistance. One of the primary uses of steel strips in the production of automotive fasteners is for forming the body of the fasteners themselves. The strips are cut into specific widths and lengths, and then undergo processes such as stamping, bending, and rolling to shape them into the desired fastener design. This ensures that the fasteners have the necessary structural integrity to perform their intended function effectively. Moreover, steel strips are also used to create threads on fasteners. These strips are rolled or cold-formed to create threads with precise dimensions and profiles. The threads are crucial for securely fastening components together, as they allow for easy insertion and tightening of the fastener. Additionally, steel strips are often coated or treated to enhance their performance in automotive applications. For example, they can be coated with zinc, chrome, or other corrosion-resistant materials to protect the fasteners from rust and other forms of deterioration. This is particularly important in the automotive industry, as vehicles are exposed to various environmental factors such as moisture, salt, and chemicals. In summary, steel strips play a vital role in the production of automotive fasteners. They are used to form the body of the fasteners, create threads, and provide corrosion resistance. By utilizing high-quality steel strips, automotive fasteners can meet the stringent requirements of the industry in terms of strength, durability, and longevity.

- Q: What are the cutting options available for steel strips?

- Depending on the specific requirements and desired outcome, there are several cutting options available for steel strips. One common method is shearing, which involves using a shearing machine with two blades to slice through the material. Shearing is ideal for straight cuts and can be used for both thin and thick steel strips. Another option is laser cutting, which uses a laser beam to melt and vaporize the steel strip. This method is precise and efficient, making it perfect for intricate and complex designs. However, it may not be suitable for very thick steel strips. Waterjet cutting is a versatile method that utilizes a high-pressure stream of water mixed with an abrasive material. It can handle various thicknesses of steel and is ideal for cutting heat-sensitive materials or those with a high melting point. Plasma cutting, on the other hand, involves ionizing gas and an electric arc to cut through the steel strip. It is effective for both ferrous and non-ferrous metals and can handle different thicknesses. Plasma cutting is known for its speed and ability to cut through thicker materials. Lastly, saw cutting uses a circular saw blade or bandsaw to cut through the steel strip. It is suitable for straight cuts and commonly used for thicker steel strips or when precise shapes are not required. When selecting a cutting method for steel strips, it is crucial to consider factors such as desired precision, speed, complexity of the design, and material thickness. Each cutting option has its advantages and limitations, so it is important to choose the most appropriate method based on the specific needs of the project.

- Q: How are steel strips used in the production of transformers?

- Steel strips are used in the production of transformers to create the core, which is the main component responsible for transferring and transforming electrical energy. The steel strips are stacked and wound together to form the core, providing a magnetic circuit that helps in the efficient transmission of electrical power.

- Q: How do steel strips perform in electromagnetic shielding?

- Steel strips can be highly effective in electromagnetic shielding due to their strong magnetic properties. They are capable of redirecting and absorbing electromagnetic radiation, preventing it from penetrating or escaping the shielded area. Steel strips also provide a low resistance path for electric currents, helping to minimize the impact of electromagnetic interference on sensitive electronic devices.

- Q: What's the difference between hot rolled strip and cold rolled strip? What's the difference between hot rolled coil and cold rolled coil?

- Hot rolled coil is above the recrystallization temperature of rolling, cold-rolled plate refers to the recrystallization temperature following rolling, popular point that is in the hot strip rolling red hot state, while cold rolled hot-rolled is under normal temperature rolling. Hot plate often said refers to the hot rolled plate, cold plate refers to the cold rolled plate, hot rolled, cold rolled and hot rolled coil is said and cold rolled coil.

- Q: What's the difference between strip 235 and 235b?

- Q235 is Q235a, Q235 material according to the sulphur and phosphorus content from high to low is divided into ABCD four grades, grade a sulfur phosphorus was the highest relative performance (welding, plasticity) is the worst, D performance is the highest, the lowest content of parathion

- Q: What are the different sizes of steel strips available?

- Steel strips are available in a wide range of sizes to accommodate various applications and industry needs. The sizes of steel strips typically vary in terms of width, thickness, and length. In terms of width, steel strips can range from as narrow as a few millimeters to several hundred millimeters, depending on the intended use. Narrow steel strips are commonly used in applications such as electrical enclosures, automotive components, and small-scale machinery. On the other hand, wider steel strips are often utilized in construction, manufacturing of large equipment, and structural applications. The thickness of steel strips can also vary significantly. Thin steel strips, typically measuring a few millimeters or less, are used in applications requiring flexibility and weight reduction, such as in the production of electronic devices, packaging materials, and thin-walled tubing. Thicker steel strips, ranging from several millimeters to a few centimeters, are employed in heavy-duty applications such as construction, shipbuilding, and industrial machinery. Regarding length, steel strips are commonly supplied in coil form, which allows for easy handling and transportation. The length of steel strips in a coil can vary depending on the manufacturer and customer requirements. Standard coil lengths typically range from a few meters to several hundred meters, ensuring that steel strips can be easily cut and shaped to fit specific project needs. In conclusion, the sizes of steel strips available are diverse, with variations in width, thickness, and length, allowing for a broad range of applications in various industries.

Send your message to us

Premium Colorful Corrugated GI Galvanized Metal Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords