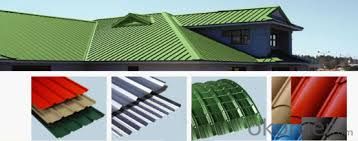

pre-painted Steel Rolled/Prepainted Cold Rolled Galvanized Steel Sheet Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Product | Galvanized | PPGI | Contour plate

| Camouflage plate | |

Certificate | ISO9001,ISO14001 | ||||

Standard | ASTM A526 JIS G3302 | ASTM A525 JIS G3312/3322 | - - | - - | |

Gade | CGCC/CGLCC CGCH/CGLCH CGC340-570 CGLC400-570 | SGCC/CS/DX51D SGCH | - - - - | - - - - | |

Model | Thick:0.11-1.0mm Width:600-1250mm | Thick:0.14-3.5mm Width:600-1250mm | Thick:0.14-3.0mm Width:600-1250mm | Thick:0.14-3.5mm Width:600-1250mm | |

Type | Roil/Coil Sheet/Plate Corrugated Sheet | Roil/Coil Sheet/Plate Corrugated Sheet |

Corrugated Sheet | Roil/Coil Sheet/Plate Corrugated Sheet | |

Coil Weight | 3-8t | ||||

Surface Finish | Regular Spangle | Pre-painted | Pre-painted | Pre-painted | |

Application | Roofing,Structural,Commercial use,Household Applicnce,Industry,Others | ||||

Special Application

| Wear resdentant steel,High-strength-steel plate | ||||

Name | GI / GL / PPGI / PPGL |

Full name | Galvanized ,Galvalume,Pre-paited galvanizing,Pre-paited galvalume |

Basic material | Cold Roll |

Color of the PPGI and PPGL | Any color in RAL |

Standard | AISI, ASTM, BS, DIN, GB, JIS |

Spangle | Normal / Min / Zero |

Brand Name | |

Thickness | 0.6mm |

Width | 600mm to 1250mm |

Length | According to customers |

Surface Treatment | Hop-dipped Galvanized |

AZ coating | 50-275g/m2 |

Spangle | Normal/Min/Zero |

Minimum order | 25 Metric Tons |

Place of Origin | Shandong, China(Mainland) |

Packing | Fully Applicable for exporting seaworthy packing of horizontal type on wooden skids |

Price terms | FOB Qingdao |

Terms of payment | T/T, L/C or T/T and L/C |

Delivery Detail | within 7-25 days after receiving pre-payment (as per the order quantity) |

Coil ID | 508mm/610mm |

Coil Weight | 3-5 tons |

Supply Ability | 30000MT per month |

Application | Construction Structure, roofing, commercial use, household appliance, industry- |

- Q: What is the average cost of shipping steel coils?

- The average cost of shipping steel coils can vary depending on various factors such as the distance, weight, dimensions, and shipping method. It would be best to contact shipping companies or freight forwarders for accurate and up-to-date pricing information.

- Q: What are the main factors that affect the price of steel coils?

- The main factors that affect the price of steel coils include the cost of raw materials, such as iron ore and scrap metal, as well as the demand and supply dynamics in the market. Other influential factors include energy costs, transportation expenses, production capacity, and geopolitical factors that can impact global trade. Additionally, fluctuations in currency exchange rates and government regulations on trade and tariffs can also influence the price of steel coils.

- Q: How much does a steel coil weigh?

- The weight of a steel coil can vary depending on its size, thickness, and type of steel used. On average, steel coils can weigh anywhere from a few hundred pounds to several tons.

- Q: What is the type of stainless steel used in knifes.

- There okorder / Stainless steel doesn't make the best knife blade. It doesn't sharpen as sharp or hold its edge as well. High carbon steel is better, but it rusts and discolors very easily so it's not as popular. A new thing (actually not new but popular these days) is to use a 'sandwich' of high carbon steel between two layers of stainless. So the actual edge is high carbon steel but the blade looks like stainless. I have some kitchen knives made this way (kind of expensive) and I love them. This same technique was used in Japanese katanas, swords used by samurai warriors.

- Q: What are the different types of welding used for steel coils?

- There are several different types of welding used for steel coils, depending on the specific requirements and applications. Here are some of the most common types of welding techniques used for steel coil fabrication: 1. Shielded Metal Arc Welding (SMAW): Also known as stick welding, it involves the use of a flux-coated electrode and an electric current to create an arc between the electrode and the base material. SMAW is a versatile and widely used welding technique suitable for various steel coil applications. 2. Gas Metal Arc Welding (GMAW): Commonly known as MIG (Metal Inert Gas) welding, GMAW uses a continuous wire electrode and a shielding gas to protect the weld pool from atmospheric contamination. GMAW is known for its high welding speed and ease of automation, making it a popular choice for steel coil manufacturing. 3. Flux-Cored Arc Welding (FCAW): Similar to GMAW, FCAW uses a tubular electrode with flux inside. The flux provides both the shielding gas and additional alloying elements, resulting in increased efficiency and improved weld quality. FCAW is often used in high-speed welding applications for steel coils. 4. Gas Tungsten Arc Welding (GTAW): Also known as TIG (Tungsten Inert Gas) welding, GTAW uses a non-consumable tungsten electrode and an inert gas, typically argon, to shield the weld area. GTAW produces high-quality, precise welds with excellent control over the heat input, making it suitable for thin steel coil materials and critical welding applications. 5. Submerged Arc Welding (SAW): This welding technique involves the use of a continuously fed wire electrode and a granular flux that covers the weld area. The arc is submerged under the flux, providing excellent protection and reducing the need for post-weld cleaning. SAW is commonly used for welding thick steel coils due to its high deposition rates and deep penetration capabilities. These are just a few examples of the different types of welding techniques used for steel coil fabrication. The choice of welding method depends on factors such as the specific steel grade, thickness, desired weld quality, production speed, and cost considerations. It is essential to select the appropriate welding technique to ensure the durability and performance of the steel coils in various applications.

- Q: PLS tell me all Foam Steel Characteristics and use?Thanks

- Foam steel [often steel foam] is used in applications that require light weight but high rigidity and strength. Watertight doors on modern ships are often made of foam steel. Pressure doors on aircraft are possible uses. As we keep striving for lighter weights in cars, foam steel might have some useful applications in bodies. There is a technical paper online that is in .pdf format that has a good discussion of the process and characteristics of foam steel.

- Q: What are the main factors that affect the paint adhesion on steel coils?

- The main factors that affect paint adhesion on steel coils include surface cleanliness, surface roughness, surface preparation methods, coating formulation, and application technique.

- Q: How are steel coils used in the manufacturing of construction reinforcement bars?

- Steel coils are used in the manufacturing of construction reinforcement bars by being processed through a series of steps. The coils are first uncoiled and then straightened before being cut to the desired length. These cut lengths are then shaped and bent into the required reinforcement bar shape using specialized machinery. Finally, the bars are heat-treated and cooled to enhance their strength and durability. Overall, steel coils serve as the primary raw material for the production of construction reinforcement bars, providing the necessary strength and structural integrity to concrete structures.

- Q: I'm in the middle of a remodel and buying appliances. Is there any way to ensure that the stainless steel is the same tone if you get different brands?

- Stainless steel is pretty much stainless steel. The differences in tone you can get is when you get stainless steel look appliances. They tend to be a bit more like a charcoal color than true stainless steel color. When I bought my house, it had a stainless steel GE microwave, dishwasher, and stove, and a Braun stainless steel range hood. When we remodeled last year, we got a Maytag Ice20 stainless steel refrigerator and a Kholer stainless steel sink. They all look fine together.

- Q: like the steel industry and the effects it had on industrial growth, 10 points!

- The single most important important advance in steel production was learning to accurately control carbon content. This was done through the Bessemer Process in which air was blown through molten iron to burn out impurities and excess carbon. Low carbon iron (wrought iron) could be easily worked into shapes. Medium carbon iron could be cast into useful and durable shapes. High carbon steel could be used for structural uses (beams and girders). Adding alloys such as nickel and silicon could produce very tough steels and steels resistant to rust. Adding vanadium to steel engine parts allowed Ford to produce finely machined engines in huge numbers with existing machinery.

Send your message to us

pre-painted Steel Rolled/Prepainted Cold Rolled Galvanized Steel Sheet Coil

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords