Pre-Painted Galvanized Steel Sheet,Coil with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

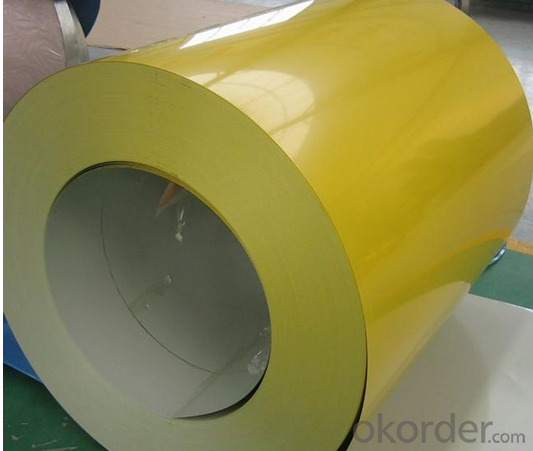

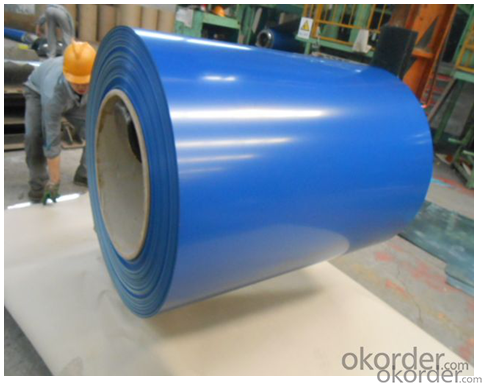

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: What is the weight of a standard steel coil?

- The weight of a standard steel coil can vary, but on average, it ranges from 10 to 20 tons.

- Q: How are steel coils used in the production of metal partitions?

- The production of metal partitions relies heavily on steel coils, which are a vital ingredient. These coils, typically made from top-notch steel, act as the primary material for manufacturing the partitions. To begin with, the steel coils undergo a process called slitting, where they are sliced into narrower strips of the desired width. This step allows manufacturers to tailor the size of the metal partitions according to specific project requirements. Following slitting, the steel strips are fed into a roll forming machine. This machine gradually transforms the strips into the desired profile for the metal partitions. The roll forming process involves passing the steel strips through a series of rollers, which progressively bend and shape the metal into the desired form and dimensions. Once the metal has been shaped as desired, it is then cut into appropriate lengths to create individual partitions. These partitions undergo further processing, such as welding or spot welding, to join different components and enhance their structural integrity. Steel coils are highly preferred for metal partition production due to their strength, durability, and versatility. The use of steel ensures that the partitions can withstand heavy loads, resist corrosion, and offer long-lasting performance. Moreover, steel coils provide a high degree of design flexibility, allowing for the creation of various partition styles, including solid panels, perforated screens, or mesh partitions. All in all, steel coils play a pivotal role in the production of metal partitions by providing the necessary raw material, strength, and customization options required for these adaptable architectural elements.

- Q: For the purpose of blade crafting. I need to heat treat this low quality steel i got.It's ASTM A36Is heat treatable and temperable?

- A36 is plain carbon structural steel. A36 could almost be considered junk steel. It is not suitable for cutting tools in any respect, as it is far to soft to hold an edge. A36 generally cannot be heat-treated, A36 can only be strengthened by cold-working, and even then, only up to about 60,000 psi. Heating the steel will only make it softer. The only real virtue of A36 is that it's easy to work with, it's easily cut and machined and it is very easy to weld. This is good for making steel structure, but not for knives. Probably the most popular material for knife blades is type 440C stainless. 440C is easy to work with in the un-treated state, and the heat treatment procedure is relatively simple.

- Q: So, I'm looking into steel toe paddock boots. I'll be using them around horses, horses that I don't know and that are rescue horses. I'm currently looking at Equitector the Moorland paddock boots. They're $200, and I think I have to order them online. I like boots that are this style (the Moorland style)... Is there any other brand of boots that has steel toe paddock boots, that are cheaper or that I can buy in stores?

- I personally know a trainer who is friends with a cowboy who got his toes amputated by a horse stepping on his steel toed boot. I personally prefer a broken toe or a bruised toe. I wouldn't recommend them. If you get your toe stomped and you happen to be standing on pavement or other hardpacked surface...you're going to regret you ever bought them. there's a reason why not a lot of horse people wear them. As for price....$200 is an average price for good boots of any kind. My first western leather boots were Tony Llamas and they were $200. I bought them YEARS ago and they're still just great.

- Q: How are steel coils unloaded from a truck?

- Typically, specific equipment and a well-coordinated process are utilized to unload steel coils from a truck. To ensure the safe and efficient removal of the coils, the unloading process consists of multiple steps. First, a forklift or crane is commonly employed to reach into the truck bed and secure the steel coil. The operator of the forklift or crane carefully positions the lifting apparatus underneath the coil, ensuring that it is centered and balanced. Once the steel coil is securely fastened, the forklift or crane gradually raises it out of the truck bed while maintaining stability. The operator must exercise caution and consider factors such as the weight and dimensions of the coil to prevent any accidents or damage. After the steel coil is lifted out of the truck, it is typically placed onto a designated area, such as a flatbed trailer, storage rack, or directly onto the ground. If placed on the ground, wooden blocks or rubber mats are often utilized as protective measures to prevent any damage to the coil or the surface it is placed on. In certain instances, a specialized coil trailer equipped with hydraulic systems may be used to unload the steel coils. This method is particularly beneficial for unloading larger and heavier coils, as it allows for the tilting of the trailer bed and rolling off the coil. In conclusion, unloading steel coils from a truck necessitates skilled operators, appropriate lifting equipment, and adherence to safety protocols. It is crucial to meticulously follow these steps to ensure the safe and efficient unloading of steel coils.

- Q: How do steel coils withstand extreme temperatures?

- Steel coils are able to withstand extreme temperatures due to the unique properties of steel. Firstly, steel has a high melting point, allowing it to maintain its structural integrity even at extremely high temperatures. Additionally, steel has excellent thermal conductivity, which enables it to evenly distribute and dissipate heat. Furthermore, steel undergoes various heat treatment processes during manufacturing, such as quenching and tempering, which enhance its strength and resistance to temperature fluctuations. Overall, these factors make steel coils highly capable of withstanding extreme temperatures.

- Q: Myself, iam Working In a Steel Fabrication Company. I completed my Engineering in 2006 and immediately recruited in this company in Oman. My company is Steel Fabrication company .So as i am new to this field, i just need some basic knowledge regarding this Steel Fabrication.Waiting for ur early reply.

- make searches on internet; it's the best way to learn.

- Q: Already on my team is Empoleon lvl 82Heatran lvl 74Scizor lvl 34Magnezone lvl 38What other steel types should I choose?

- Metagross would help out a lot, Excadrill id you are not doing double battles... (two of his best moves for him hit his team and are ground.. ) if you do not want to rick excadrill use a Lucario instead for hs massive damage output.

- Q: How are steel coils used in the production of metal cabinets?

- Steel coils are an essential component in the production of metal cabinets. These coils are made from thin sheets of steel that have been wound into a tightly coiled shape. The first step in using steel coils for metal cabinet production is uncoiling them. This is done by unwinding the coil and feeding the steel sheet into a machine that cuts it to the desired length. The length of the sheet will depend on the size and dimensions of the metal cabinet being produced. Once the steel sheet has been cut, it undergoes a process called blanking. This involves cutting out the various panels and parts needed for the metal cabinet, such as the sides, top, bottom, and doors. The blanking process is typically done using a stamping press or a laser cutting machine, which ensures precision and accuracy in shaping the steel sheet. After the blanking process, the individual panels are then formed and shaped using a series of bending and forming machines. These machines apply pressure and force to the steel panels, bending them into the desired shape and creating the necessary angles and curves required for the metal cabinet design. Once the panels have been formed, they are usually joined together using welding or fastening techniques. Welding involves fusing the edges of the steel panels together using heat, while fastening techniques may involve using screws, bolts, or rivets to secure the panels in place. Overall, steel coils play a crucial role in the production of metal cabinets as they provide the raw material from which the individual panels are made. The use of steel coils allows for greater flexibility and efficiency in manufacturing metal cabinets, as it enables mass production and customization of cabinet designs.

- Q: We have to do a project for school on steel mines and i need 4 PROPERTIES OF A STEEL MINE PLEASE HELP!!! URGENT!!!

- The existence of them would be a good start. Steel is produced from iron ore, not mined.

Send your message to us

Pre-Painted Galvanized Steel Sheet,Coil with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords