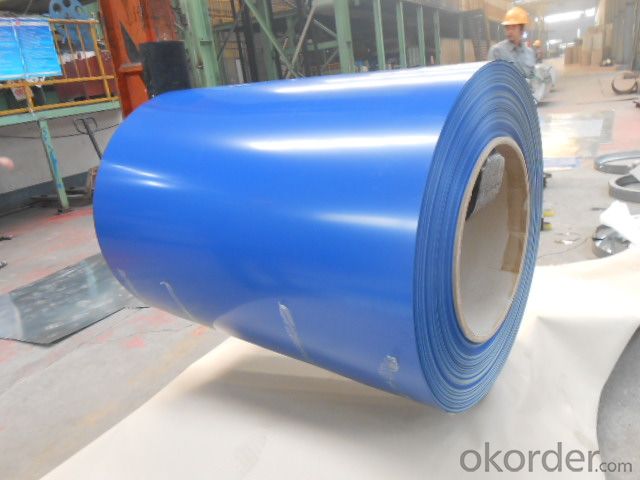

Pre-Painted Galvanized Steel Sheet/Coil with Prime Quality Blue Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

4. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

5. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: How are steel coils used in the production of storage shelves?

- Steel coils are an essential component in the production of storage shelves. These coils are typically made from carbon steel and undergo a series of processes to shape them into the desired form. The first step in using steel coils for storage shelves is to unroll and flatten the coil. This is done using a machine called a decoiler, which unwinds the coil and feeds it through a series of rollers to flatten the metal. Once the coil is flattened, it is ready for further processing. Next, the flattened steel is cut into specific lengths using a shearing machine or a saw. These cut pieces are then bent and shaped into the appropriate dimensions for the storage shelves. This bending process is typically done using a press brake or a roll former, which applies pressure to the metal to create the desired shape. Once the steel has been shaped into the proper dimensions, it is welded together to form the structure of the storage shelf. This welding process ensures that the shelves are strong and durable, capable of supporting heavy loads. After the welding is complete, the storage shelves may undergo additional processes such as surface treatment or coating to enhance their appearance and protect them from corrosion. These treatments can include processes like powder coating, galvanization, or painting. Overall, steel coils play a crucial role in the production of storage shelves. They provide the raw material from which the shelves are made, and their versatility allows for a wide range of shapes and sizes to be created. The strength and durability of steel make it an ideal choice for storage shelves, ensuring that they can withstand heavy loads and provide long-lasting storage solutions.

- Q: What are the different types of steel coatings used on coils?

- There are several types of steel coatings used on coils, including galvanized coatings, galvannealed coatings, and organic coatings.

- Q: How are steel coils used in the manufacturing of fasteners?

- Steel coils are commonly used in the manufacturing of fasteners because they provide a cost-effective and efficient way to produce large quantities of fasteners. The steel coils are unwound and then fed into machines that cut, shape, and thread the steel to create various types of fasteners such as screws, bolts, and nails. The high strength and durability of steel make it an ideal material for fasteners, ensuring secure and reliable connections in a wide range of applications.

- Q: Does te game end with broken steel? What is broken steel? I bouht it cuz my buddy said I should.

- you will see the conventional ending on the tip, yet once you have BS downloaded you will awaken to start up a sparkling quest extremely than having the activity in basic terms end. Vault one 0 one won't open back up, you in basic terms get to bypass back for the hassle on the homefront quest. and 3, as quickly as you have BS downloaded the activity will never end

- Q: What are the common coil widths and thickness combinations available for steel coils?

- Common coil widths for steel coils range from 600mm to 2000mm, while common thickness combinations vary from 0.4mm to 3.0mm.

- Q: What are the common surface defects in steel coils?

- Steel coils commonly have surface defects, including scratches, pits, indentations, stains, and rust spots. Scratches may occur due to mishandling or processing, and their depth and length can vary. Pits are small depressions caused by impurities in the steel or during manufacturing. Indentations are similar but larger and more noticeable. Stains can result from chemicals, water, or other contaminants coming into contact with the steel. Rust spots form when the steel is exposed to moisture or corrosive elements, leading to iron oxide formation. These defects can impact the appearance, quality, and performance of the steel, necessitating their resolution to ensure the intended use of the coils.

- Q: What are the common methods of protecting steel coils from corrosion during storage?

- To safeguard steel coils from corrosion during storage, there are multiple commonly employed techniques. These methods aim to shield the steel coils from moisture and other environmental factors that could trigger corrosion. 1. VCI (Volatile Corrosion Inhibitor) Packaging: VCI packaging is extensively utilized for steel coil protection. It incorporates VCI materials into the packaging, such as plastic bags or films. These materials emit a vapor that forms a protective layer on the surface of the steel coils, effectively preventing the intrusion of moisture and corrosive agents. 2. Oil Coating: Another widely adopted approach involves applying a thin layer of oil onto the steel coil surface. This oil acts as a barrier, obstructing the contact between the steel and moisture or oxygen. It proves particularly effective for long-term storage or transportation situations. 3. Desiccants: Silica gel packets or similar desiccants can be placed inside the packaging to absorb any trapped moisture. By reducing humidity levels within the packaging, the risk of corrosion is minimized. This method is often combined with VCI packaging or oil coating. 4. Proper Ventilation: Adequate ventilation is crucial to prevent moisture buildup around the steel coils during storage. By facilitating the free circulation of air, humidity levels are reduced, and the formation of condensation, which can lead to corrosion, is prevented. 5. Controlled Environment: Storing steel coils in a controlled environment is an effective corrosion prevention measure. This entails maintaining constant temperature and humidity levels that are unfavorable for corrosion. Temperature and humidity control can be achieved using air conditioning or dehumidification systems. It should be noted that the choice of specific protection methods or combinations thereof depends on various factors, including storage duration, environmental conditions, and specific steel coil requirements. Regular inspections and maintenance are also vital to ensure ongoing corrosion protection.

- Q: Are steel coils corrosion-resistant?

- Yes, steel coils can be made corrosion-resistant through various methods such as coating them with protective layers or using corrosion-resistant alloys.

- Q: How do steel coils differ in terms of size and weight?

- The size and weight of steel coils can vary greatly depending on their intended use and production process. When it comes to size, a steel coil is typically measured by its outer diameter, inner diameter, and width. The outer diameter refers to the total diameter of the coil, while the inner diameter refers to the diameter of the hollow center. The width, on the other hand, is the distance between the two flat sides. In terms of weight, steel coils can range from a few hundred pounds to several tons. The weight primarily depends on the size and type of steel used. Coils made from high-strength steel are generally heavier because they have a higher density. On the contrary, coils made from lower-grade steel can be lighter. The size and weight of steel coils play a crucial role in their transportability and handling. Smaller and lighter coils are easier to handle and transport, making them suitable for applications that require maneuverability. On the flip side, larger and heavier coils are commonly used in industries that prioritize strength and durability, like construction and automotive manufacturing. All in all, steel coils come in various sizes and weights, allowing for customization and meeting specific requirements in different industries.

- Q: The knife will be large and thick. Like the Bowie knife Rambo uses in Rambo III. It doesn't need to be flexible or to hold the edge very well. But i need it to be exceptionally strong material and to stop corrosion at least decently. Is Damascus Steel good?Thank you, in advance.

- If it does not could desire to hold an part o.k. then 440 stainless could be your appropriate guess. I want severe carbon steel. yet they require alot of cleansing and oiling or they're going to rust.

Send your message to us

Pre-Painted Galvanized Steel Sheet/Coil with Prime Quality Blue Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords