Pre-Painted Galvanized Steel Sheet/Coil High Quality Prime

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted Galvanized/Aluzinc Steel Coil Description

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling,

2.Main Features of the Pre-painted Galvanized/Aluzinc Steel Coil

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

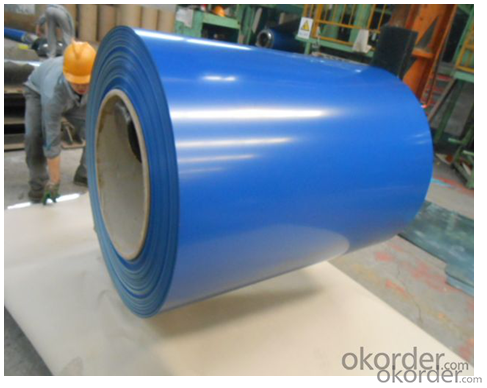

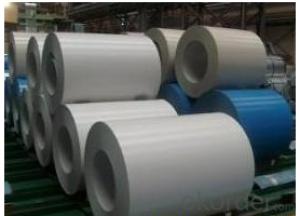

3.Pre-painted Galvanized/Aluzinc Steel Coil Images

4.Pre-painted Galvanized/Aluzinc Steel Coil Specification

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, green color.

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

5. FAQ of Pre-painted Galvanized/Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How are steel coils inspected for hardness?

- Various methods are used to inspect the hardness of steel coils, ensuring their quality and suitability for specific applications. The Rockwell hardness test is a common method, involving the use of a diamond or ball indenter pressed into the coil's surface to measure indentation depth. The hardness value is then determined based on this measurement. Another method is the Brinell hardness test, which uses a hardened steel or tungsten carbide ball indenter to create an indentation on the coil's surface. The diameter of the indentation is measured, and the hardness value is calculated using a formula that considers the applied load and indentation diameter. On the other hand, the Vickers hardness test utilizes a pyramidal diamond indenter to create an indentation on the coil's surface. The lengths of the indentation diagonals are measured, and the hardness value is calculated using a formula that takes into account the applied load and diagonal lengths. In addition to these traditional methods, modern technology has introduced non-destructive testing techniques such as ultrasonic testing and eddy current testing. Ultrasonic testing involves transmitting ultrasonic waves through the coil and measuring the time it takes for the waves to return. Changes in the wave pattern can indicate variations in hardness. Eddy current testing, on the other hand, uses electromagnetic induction to detect changes in electrical conductivity, which can be correlated to hardness variations in the steel coil. Overall, steel coils undergo thorough inspection using a combination of traditional and advanced techniques to ensure their hardness meets the required specifications. These inspections are vital in maintaining the quality and dependability of steel products in various industries.

- Q: how many persent of manganese in all types of carbon steel

- Not more than 1.65 % of manganese in carbon steel. *Carbon steel, also called plain carbon steel, is steel where the main alloying constituent is carbon. The American Iron and Steel Institute (AISI) defines carbon steel as: Steel is considered to be carbon steel when no minimum content is specified or required for chromium, cobalt, columbium, molybdenum, nickel, titanium, tungsten, vanadium or zirconium, or any other element to be added to obtain a desired alloying effect; when the specified minimum for copper does not exceed 0.40 percent; or when the maximum content specified for any of the following elements does not exceed the percentages noted: manganese 1.65, silicon 0.60, copper 0.60 *AISI 1040 is a carbon steel which is having a 0.60-0.90 % of manganese.

- Q: Can steel coils be customized in terms of size and thickness?

- Yes, steel coils can be customized in terms of size and thickness. Manufacturers have the capability to produce steel coils in various sizes and thicknesses to meet the specific requirements of different industries and applications.

- Q: I have a knife with AUS8 Stainless Steel. No idea what that means. I want to know some of the best stainless steels for knifes and all you can tell me about stainless steel would be great. I was browsing google and looking at grades and had no idea what all the numbers meant. Thanks!

- Actually-good grades of stainless is superior to high carbon steels which has been proven by countless tests. Aus8 is a japanese steel from what I know, so I'm not sure what the letter and number designation means. From what I know, Aus8 has similar properties to 440B though with a carbon content of around ~.74%. This is lower content then most other blade steels meaning it has lower edge retention. The stainless steels I'd consider to be best are: Ats-34: Less corrosion resistant then 440c, but is tougher then 440c and still holds a edge quite well 440c: Probably the best all around steel on the market for its price. Highest corrosion resistance and very good edge retention. I wouldn't recommend it on choppers though, a tougher steel like the one mentioned above would probably be better for that. A/B/C indicates the carbon content going from least to greatest. 4xx indicates that its a chrome martensitic steel. 40 indicates that its a high carbon grade compared to (4)20 which has less then .5 percent. CpmS30v: Slightly lower corrosion resistance then 440c due to it not taking a mirror finish, but very high edge retention and improved toughness. Cpm indicates that it's made by compressed particle metallurgy while the v indicates that its a vanadium alloy. I'm not sure what the S30 indicates.

- Q: For robotics homework, I need to find out how steel is galvanized and why. I researched a little bit, and I'm not sure I grasp the entire concept. Simple words would be helpful :) Thank you!!!

- Steel can be galvinised by electroplating process. Galvinising means providing a zinc coating on steel surface. It protects the material from rusting and loosing the shinining.

- Q: How do steel coil manufacturers handle international shipping requirements?

- Steel coil manufacturers typically handle international shipping requirements by following a well-defined process. First, they ensure proper packaging and securing of the coils to prevent damage during transportation. This may involve using specialized equipment, such as coil racks or crates. Next, they comply with international shipping regulations and obtain necessary documentation, such as bills of lading and customs clearance forms. They coordinate with freight forwarders or shipping agents to arrange transportation and select the most suitable shipping method, whether it's by sea, air, or land. Throughout the process, manufacturers closely track shipments and communicate with customers to ensure smooth delivery and address any issues that may arise.

- Q: Perform three sets of 15 repetitions several times a week and you will soon have buns of steel.

- That particular exercise will develop the buttock muscles, or the gluteous maximus. In other words, your butt, sometimes referred to as buns, along with many other euphemisms.

- Q: What are the different grades of steel used for manufacturing coils?

- The different grades of steel used for manufacturing coils include low carbon steel, medium carbon steel, high carbon steel, and stainless steel.

- Q: if someone wanted to melt cast steel or iron into small-relatively simple shapes such as rod-tapered rod-or etc... how would you go about melting the steel/iron what would the mold need to be made of?

- Steel is melted in a cupola furnace. you don`t cast rods you cast a large ingot and then while its red hot and still soft it is rolled in between gradually reducing shaped rollers so it gets stretched out and the structure of the metal makes it less likely to snap.

- Q: What are the common transportation defects in steel coils?

- There are several common transportation defects that can occur in steel coils. One of the most common is coil damage caused by improper handling or securing during transportation. This can result in dents, scratches, or even tears in the steel. Another common defect is coil edge damage, which can occur if the coils are not properly protected or if they rub against each other during transit. This can lead to deformation or even breakage of the coil edges. Additionally, coil shifting is another common defect, which happens when the coils are not properly secured or braced, causing them to move and shift during transportation. This can result in misalignment or damage to the coils. Finally, coil corrosion is a common defect that can occur if the coils are exposed to moisture or other corrosive elements during transportation. This can lead to rust and deterioration of the steel. Overall, proper handling, securing, and protection measures are crucial in order to prevent these common transportation defects in steel coils.

Send your message to us

Pre-Painted Galvanized Steel Sheet/Coil High Quality Prime

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords