Pre-painted Galvanized Steel Coil Used for Industry with Our Very Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-painted Galvanized Steel Coil Used for Industry

1.Structure of Pre-painted Galvanized Steel Coil Description

With GI as base metal, after pretreatement and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of Pre-painted Galvanized Steel Coil

•High Purity

•Easy control and operation

•High strength

•Fast melting

•Competitive price

•Best Service

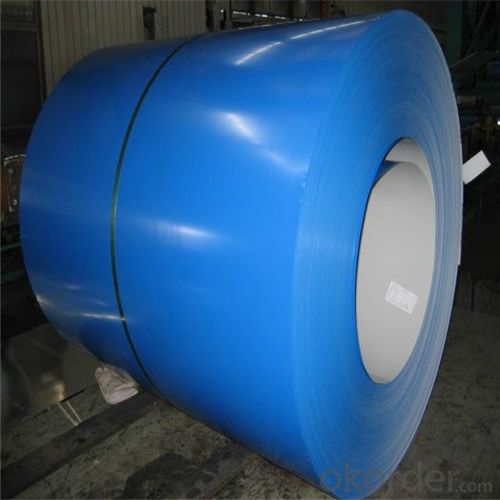

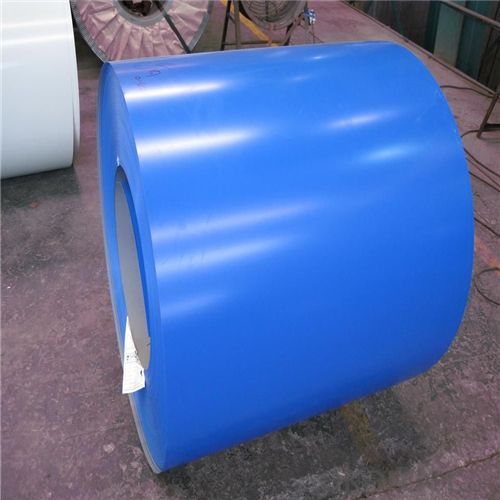

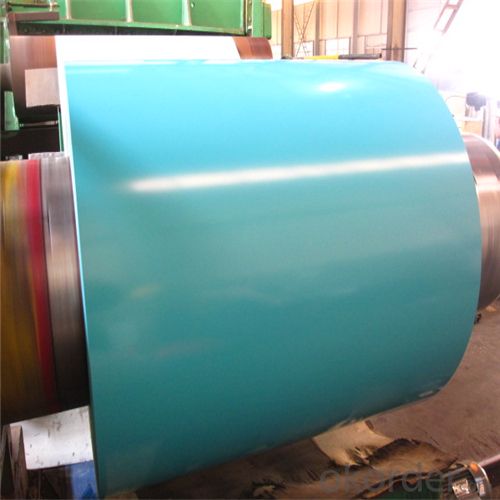

3. Pre-painted Galvanized Steel Coil Images

4. Pre-painted Galvanized Steel Coil Specification

Pre-painted Galvanized Steel Coil | |

Thicknenss | 0.18mm-1.5mm |

Width | 900-1250mm |

Coating mass | 30-275g/㎡ |

Paint | PE, PVDF, PU |

Color | RAL Scale |

Coil weight | 3-7mt |

Coil inner diameter | 508 or 610mm |

5.FAQ of Hot-Dip Galvanized Steel Coil

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

We can supply customers' with different specifications of the highest quality and lowest price.

Sincerely welcome to contact us for the future details if any item interest you ,and we will make every effort to assure that your requirements will be satisfied ,and we hope to establish long-term business relations with you on the basis of the equality and mutual benefit.

We are waiting for your email.

- Q: How are steel coils used in the manufacturing of industrial filters?

- Steel coils are used in the manufacturing of industrial filters to create the framework or structure that holds the filter media in place. The steel coils are shaped and welded together to form the desired size and shape of the filter, providing stability and durability to the final product.

- Q: What are the advantages of using hot-rolled steel coils?

- Hot-rolled steel coils offer several advantages, including improved strength, durability, and formability. The high temperature during the rolling process allows for better shaping and molding, making it suitable for various applications. Additionally, hot-rolled steel coils have a smoother surface finish and are more cost-effective compared to cold-rolled steel coils.

- Q: Can steel coils be welded?

- Yes, steel coils can be welded. Welding is a widely used process for joining metal components, including steel coils.

- Q: I'm looking for the weight of different types of steel and haven't found anything helpful!!thank you

- Just know the type of steel ,its density. Density gives you weight per unit of volume. For example: The density of mild steel is approximately 7.85 g/cm^3 (0.284 lb/in^3) From above , you can say that 1 cm^3 of volume of mild steel have 7.85 gram weight.

- Q: given the buoyant economic growth of india, what you guys think about steel industry? what can be the major issues in this industry in the coming days

- NAFTA became a unfastened commerce contract it is fairly a lot a republican proper. unfastened markets are a sturdy element. each and every so often unfastened markets deliver approximately the shortcoming of jobs in one sector yet that would not advise unfastened commerce is undesirable. opposition like that ensures that capital is spent in it is best way. Proping up death industries isn't a sturdy concept. i know it is not a favored element to declare, even though it is the certainty. would desire to we've propped up the horse and carriage marketplace while autos got here alongside so as that horse handlers did not lose thier jobs? in all risk not. unfastened commerce is a sturdy element. That being mentioned, i don't think of that Obama will merely blanketly wipe out any coverage by means of fact it became a Bush coverage. he isn't that stupid. If it became a sturdy coverage that labored, i'm particular it will be retained.

- Q: What are the different packaging options for steel coils?

- The different packaging options for steel coils include wooden crates, steel frames, and coil covers.

- Q: How are steel coils used in the construction of buildings?

- Steel coils are used in the construction of buildings primarily for their strength and durability. These coils are typically formed into beams, columns, and other structural components, providing a sturdy framework. Additionally, steel coils can be shaped into sheets or plates used for roofing, walls, and flooring, offering excellent resistance to weather and fire. Overall, steel coils play a crucial role in ensuring the stability and longevity of buildings.

- Q: How are steel coils used in the production of fencing materials?

- Steel coils are used in the production of fencing materials by being unwound and flattened to create the wire used for fencing. The steel wire is then further processed and shaped into different forms, such as chain link or barbed wire, to meet specific fencing needs.

- Q: so why shouldn't one use a steel cased 223 in an ar15?

- Because some people ***** and moan about how the lacquer or polymer gums up the chamber causing torn case rims. But they don't clean there guns anyway so there point is irrelevant. Some say it wears out your extractor faster which is also bullshit. The steel casings are a milder bi-metal. Really its people complaining for the sake of complaining.

- Q: I know that steel wool is coated with... something... that protects it from rusting. I need to know what that is, and how to get it off.

- spun steel fibers have a microscopic coating of oil to prevent them from rusting. Rusting steel wool wouldn't sell very well. I would think that removing this oil could be accomplished with any good degreaser, like brake cleaner or the like. However, I've never tried this before. In science class they perform experiments by removing the oil with vinegar. After wringing out the steel wool pad, it is wrapped around a thermometer and placed in a sealed jar. After a few minutes the temperature rises because of the chemical reaction that takes place when four atoms of iron react with three atoms of oxygen and create two atoms of iron oxide - RUST! You can unwittingly recreate this experiment by using steel wool in the process of removing one or more layers of finish from a piece of furniture Hope this helps

Send your message to us

Pre-painted Galvanized Steel Coil Used for Industry with Our Very Good Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords