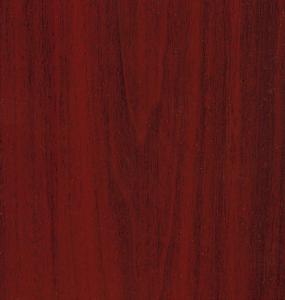

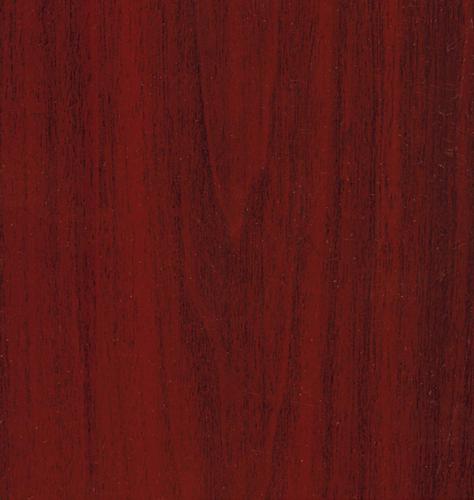

Pre-painted Galvanized Steel Coil-EN10169-WOODEN3

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 2000吨 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-painted Galvanized Steel Coils/ PPGI/GI

I Specifications:

1.Thickness:0.16-2.0mm

2.Width:600-1500mm

3.Material: SGCC,SGCD,SECC,SECD,DX51D+Z

4.Zinc coating:40-275G/M2

5.Surface Structure: galvanized ,zero spangle, regular spangle or normal spangle

6.Surface treatment: chromated and oiled, chromated and non-oiled

7.Color:all RAL series

II Main characteristics :

1.strong corrosion resistance

2.surface quality

3.conducive to deep processing,such as the embossed PPGI,printed PPGI&punching PPGI

4.economy and practicality

III Applications:

Household Appliance:

1.Refrigerator shutter &side panels, Washer, Freezers, Air conditions,

2.Rice Cooker, Microwave Ovens, Water Heaters, Sterilization Cabinets, Range Hoods

3.Computer Panels , DVD/DVB panels, TV back panel etc.

Teaching Board: whiteboard, blackboard, green board(chalk board).

Indoor Decoration: Fireproof Door, kitchen cabinet, wall decoration.

Shipping Industries: Ship, Fecht, Marine.

Elevator/Medical Equipment/Rubbish Bin.

Thickness:0.17mm-0.8mm

Width:600mm-1250mm

Prepainted Galvanized Steel Coil

- Q: How are steel coils used in the production of kitchen appliances?

- Steel coils are used in the production of kitchen appliances as they are shaped, cut, and formed into various components such as bodies, doors, panels, and frames. These coils provide the necessary strength, durability, and stability required for the construction of kitchen appliances, ensuring the longevity and reliability of the finished products.

- Q: How are steel coils used in the production of steel hooks?

- Steel coils are used in the production of steel hooks as they serve as the primary raw material. These coils are unrolled and then undergo a series of processes such as cutting, shaping, bending, and welding to form the desired shape of the hook. The strength and durability of steel coils make them an ideal material for manufacturing steel hooks, ensuring they can withstand heavy loads and provide reliable support in various applications.

- Q: How are steel coils used in the construction of bridges?

- Steel coils are indispensable in the construction of bridges, as they are typically crafted from high-strength steel and serve various purposes throughout the bridge-building process. One of the primary functions of steel coils in bridge construction lies in the production of structural components. These coils are cut, shaped, and welded together to form beams, columns, and trusses, thus ensuring the bridge's stability and durability. Moreover, steel coils are employed in fabricating bridge decks, which serve as the upper surface of the bridge, providing a pathway for vehicles and pedestrians. The coils are rolled into sheets and further processed to create the deck plates, which are then assembled and attached to the bridge's structural elements. Another significant application of steel coils in bridge construction involves reinforcing concrete structures. Rebar, derived from steel coils, is embedded within the concrete to enhance its strength and resistance to tension. Strategically placed in locations such as bridge piers and abutments, the rebar provides additional support, preventing cracking or collapse. Furthermore, steel coils find utility in the manufacturing of bridge expansion joints. These vital components allow bridges to expand and contract in response to temperature fluctuations and external factors. By shaping steel coils into plates or strips, expansion joints can be easily installed and adjusted to accommodate the bridge's movement. To summarize, steel coils play a vital role in the construction of bridges, contributing to the manufacturing of structural components, bridge decks, reinforcing concrete structures, and expansion joints. With their strength and support, steel coils facilitate the creation of safe and reliable bridges, capable of withstanding diverse loads and environmental conditions.

- Q: Can steel coils be reused?

- Yes, steel coils can be reused. Steel is a highly recyclable material, and steel coils can be melted down and used to produce new steel products. Recycling steel coils not only helps to conserve resources and reduce waste but also contributes to a more sustainable and environmentally-friendly manufacturing process.

- Q: How are steel coils used in the production of steel tanks?

- Steel coils are an essential component in the production of steel tanks. These coils, which are typically made from high-quality steel, serve as the primary raw material for manufacturing steel tanks. The first step in the process is to unroll and flatten the steel coils, which are usually delivered in a coiled form from the steel mills. Once the coils are unrolled, they are then cut into specific lengths and widths, depending on the desired dimensions of the steel tank. These cut pieces are then molded and shaped into the different components of the tank, such as the cylindrical body, the top and bottom ends, and any additional fittings or accessories. The steel coils provide the necessary strength and durability to the tank, ensuring that it can withstand the rigors of its intended application. The quality of the steel used in the coils is crucial, as it determines the tank's resistance to corrosion, pressure, and external forces. Moreover, the use of steel coils allows for efficient and cost-effective production of steel tanks. The standardized nature of the coils ensures consistent quality and dimensions, resulting in a streamlined manufacturing process. The ability to cut the coils into precise lengths and widths also minimizes wastage and maximizes material utilization. Furthermore, steel coils offer flexibility in terms of design and customization. They can be easily formed and welded into complex shapes, allowing for the creation of tanks with varying sizes, capacities, and configurations. This versatility makes steel coils an ideal choice for producing tanks for diverse sectors, including industrial, commercial, and residential applications. In summary, steel coils play a crucial role in the production of steel tanks. They provide the necessary raw material for manufacturing various tank components, ensuring strength, durability, and customization. By utilizing steel coils, manufacturers can efficiently produce high-quality tanks that meet the specific requirements of different industries.

- Q: How are steel coils used in the production of metal cladding?

- Steel coils are used in the production of metal cladding as they are rolled into flat sheets and then formed into various shapes and profiles. These coils provide the raw material for manufacturing metal cladding panels, which are widely used in construction for their durability, weather resistance, and aesthetic appeal.

- Q: How are steel coils used in the manufacturing of agricultural irrigation systems?

- Steel coils are used in the manufacturing of agricultural irrigation systems primarily for the fabrication of pipes and tubing. These coils are formed into the desired shape and size, allowing for efficient water transportation and distribution throughout the agricultural fields.

- Q: How are steel coils inspected for elongation?

- Steel coils are inspected for elongation using a variety of methods. One common method is the use of a tensile testing machine. In this method, a small sample is taken from the steel coil and placed into the machine. The machine then applies a pulling force to the sample until it breaks. The amount of force required to break the sample is measured, and this information is used to determine the elongation of the steel coil. Another method used to inspect steel coils for elongation is the use of ultrasonic testing. In this method, high-frequency sound waves are passed through the steel coil. By analyzing the reflection of these sound waves, it is possible to determine the elongation and other properties of the steel coil. Visual inspection is also an important aspect of inspecting steel coils for elongation. Trained technicians visually inspect the steel coils for any signs of stretching or deformation that may indicate excessive elongation. Overall, a combination of mechanical testing, ultrasonic testing, and visual inspection is used to thoroughly inspect steel coils for elongation and ensure their quality and compliance with industry standards.

- Q: I need help my new stainless steel cookware is sticking ? My first meal was nasty!

- Food sticks to stainless steel. Gourmet cooks love it for that very reason. Without sticking, foods won't sear properly. For the rest of those cooks out there, nonstick is often an easier option. If you want to make a go of the stainless, here are some tricks of the trade.... a)always preheat the pan on low-medium b)never put cold food into a hot pan. It will stick worse.Leave cold food on counter for 15 minutes before it hits the pan. c)after preheating the pan, add oil, or an oil/butter combo d)for foods like eggs, potatos, grilled cheese, nonstick is your best friend. e) when you take food out of pan, immediately wipe the pan out with a kitchen towel. Keeps cleanup from being a nightmare. f) don't wash pans in sink while hot. They will warp. Stainless takes some getting used to. Hope this helps!

- Q: How are steel coils used in the manufacturing of automotive fuel tanks?

- Steel coils are used in the manufacturing of automotive fuel tanks as they provide strength, durability, and resistance to corrosion. These coils are formed and welded into shape to create the fuel tank, ensuring it can withstand the pressure and vibrations associated with storing and transporting fuel safely.

Send your message to us

Pre-painted Galvanized Steel Coil-EN10169-WOODEN3

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 2000吨 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords