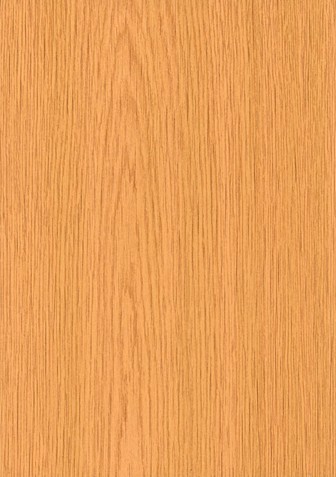

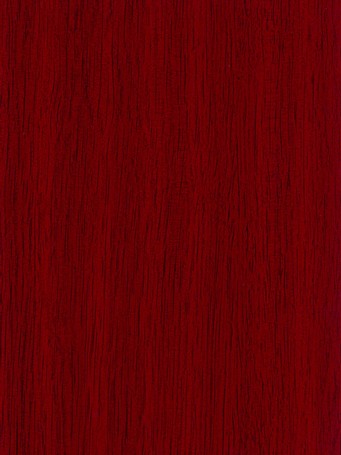

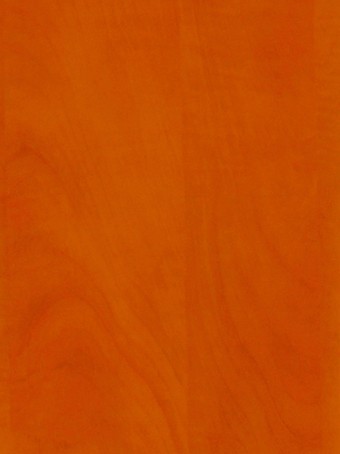

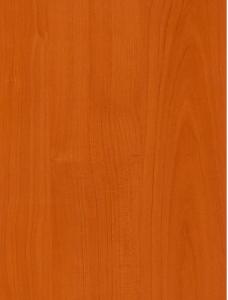

Pre-painted Galvanized Steel Coil-EN10169-WOODEN5

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 2000吨 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-painted Galvanized Steel Coils/ PPGI/GI

I Specifications:

1.Thickness:0.16-2.0mm

2.Width:600-1500mm

3.Material: SGCC,SGCD,SECC,SECD,DX51D+Z

4.Zinc coating:40-275G/M2

5.Surface Structure: galvanized ,zero spangle, regular spangle or normal spangle

6.Surface treatment: chromated and oiled, chromated and non-oiled

7.Color:all RAL series

II Main characteristics :

1.strong corrosion resistance

2.surface quality

3.conducive to deep processing,such as the embossed PPGI,printed PPGI&punching PPGI

4.economy and practicality

III Applications:

Household Appliance:

1.Refrigerator shutter &side panels, Washer, Freezers, Air conditions,

2.Rice Cooker, Microwave Ovens, Water Heaters, Sterilization Cabinets, Range Hoods

3.Computer Panels , DVD/DVB panels, TV back panel etc.

Teaching Board: whiteboard, blackboard, green board(chalk board).

Indoor Decoration: Fireproof Door, kitchen cabinet, wall decoration.

Shipping Industries: Ship, Fecht, Marine.

Elevator/Medical Equipment/Rubbish Bin.

Thickness:0.17mm-0.8mm

Width:600mm-1250mm

Prepainted Galvanized Steel Coil

- Q: How does the thickness of a steel coil affect its applications?

- The thickness of a steel coil has a significant impact on its applications. The thickness determines the strength, durability, and versatility of the steel, making it suitable for various uses across different industries. In applications where strength is crucial, such as the construction industry, thicker steel coils are preferred. Thicker coils provide higher structural integrity and load-bearing capacity, which is essential in buildings, bridges, and infrastructure projects. Thicker steel coils also offer better resistance to bending, warping, and other forms of deformation, making them ideal for heavy-duty applications. The thickness of a steel coil also affects its durability. Thicker coils have a higher resistance to wear, corrosion, and damage, making them suitable for harsh environments or applications that involve constant friction or exposure to elements. For example, thicker steel coils are commonly used in manufacturing heavy machinery, automotive parts, and mining equipment, where durability is paramount. Furthermore, the thickness of a steel coil determines its versatility and adaptability. Thinner coils can be easily formed into different shapes and sizes, making them suitable for applications that require intricate designs or tight tolerances. Industries such as automotive, aerospace, and consumer electronics often rely on thinner steel coils for their lightweight and flexible nature. On the other hand, thicker steel coils may limit the range of applications due to their weight and reduced flexibility. They are more suitable for applications that prioritize strength and durability over versatility. These applications include structural components, large-scale machinery, and industrial equipment. In summary, the thickness of a steel coil plays a crucial role in determining its applications. Thicker coils offer increased strength, durability, and resistance, making them ideal for heavy-duty applications in construction and manufacturing industries. Thinner coils, on the other hand, provide versatility and adaptability, making them suitable for applications that require intricate designs or lightweight properties.

- Q: What are the common methods of preserving steel coils?

- Some common methods of preserving steel coils include applying protective coatings, such as oil or paint, to prevent corrosion and rust formation. Another method is using VCI (Vapor Corrosion Inhibitor) paper or film, which releases chemicals that prevent oxidation. Additionally, steel coils can be stored in climate-controlled environments or wrapped in moisture-resistant materials to minimize exposure to moisture and humidity, which can accelerate corrosion.

- Q: Why is iron used to create steel? Why not other elements?

- iron came before steel. iron is what was discovered that, under certain circumstances, became a stronger metal: steel. that is why. its like asking why copper is in bronze. because what we call bronze, is an alloy of copper and tin. if you give a more detailed question, i may be able to give a more detailed answer.

- Q: where to buy Transformer steel?Used in transformers and electric motors.

- Here okorder

- Q: What are the challenges in coil recoiling?

- Some of the challenges in coil recoiling include achieving precise and consistent coiling, minimizing coil distortion and tangling, preventing material damage or breakage during recoiling, and ensuring efficient and safe handling of coiled materials. Additionally, factors such as coil size, weight, and material properties can also pose challenges in the recoiling process.

- Q: Can steel coils be recycled?

- Yes, steel coils can be recycled. Steel is a highly recyclable material, and steel coils can be melted down and reformed into new steel products without losing their quality or strength. Recycling steel coils helps to conserve natural resources, reduce energy consumption, and minimize waste.

- Q: What are the different types of steel coil leveling methods?

- There are several different steel coil leveling methods, including roller leveling, stretcher leveling, and temper leveling.

- Q: The difference between aluminized color steel roll and ordinary color steel roll

- Substrate selection: AZ150 (aluminum zinc content 150g/m2); G345A high strength galvanized steel sheet (55% aluminum, 43% zinc and 1.6% silicon) corrosion resistance data: 5%NaCL 35 DEG C, 1000Hrs, Field good, Scribe, No, Blister, 2mm belowQ.U.V: 2000hrs, MAX.2 color, light to keep the rate above 90%, the above data show that aluminum zinc coated board (AZ150, G345A, PVDF) is very suitable for the extreme environment of buildings or other facilities, highly corrosion resistance and weather resistance, and the major steel plate can ensure the service life of 20 years. In addition, high strength steel has been widely used abroad, and it has good economic performance, and it is also the domestic development trend.

- Q: bullets are normally made out of lead...are there bullets that are completely steel?? (not plated)

- They will both knock it over, but it depends on how the bullets hit the block. If the steel bullet hits the block at any kind of an angle, it will knock it over because it will enter the block cross grain. If it hits it straight on, it will not have as much resistance as it goes with the grain of the wood. The rubber bullet will have more resistance because it does not pierce the block. The force from the rubber bullet would be the same no matter what angle it comes from.

- Q: Does anyone know what colour steel is?How hard steel is?The density of steel?Conductivity of steel? (Heat and electricity)Reactivity of steel?Melting and boiling points of steel?And the malleability and ductility of steel?Ive looked all over the net and i cant find anything. Can someone please answer these questions or give me a website?THANKS!

- Steel is an alloy composed mainly of iron and carbon, but almost always contain small and various amounts of other elements. So all of these questions will have a range of answers. For example, the density of steel is between 0.280 and 0.291 pounds/cubic inch. The melting point for mild steel is around 2400F (1300C), but can be much higher, as in stainless steel which is 2800F because it contains a minimum of 11% chromium. Wiki has a legitimate definition.

Send your message to us

Pre-painted Galvanized Steel Coil-EN10169-WOODEN5

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 2000吨 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords