Pre-painted Galvanized Sheet Coil with Prime Quality and Lowest Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

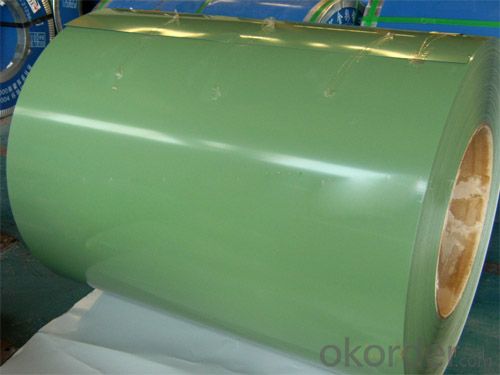

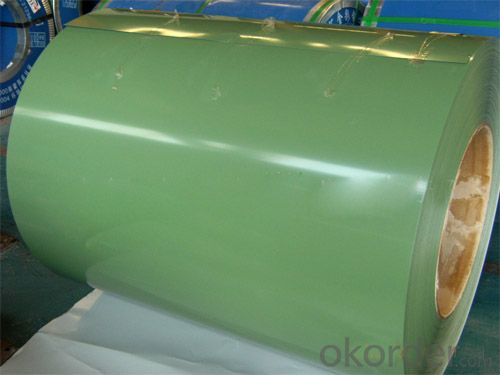

1.Structure of Pre-painted Galvanized/Aluzinc Steel Coil Description

Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance.

It generally workability, durability and weather resistance.

2.Main Features of the Pre-painted Galvanized/Aluzinc Steel Coil

• High strength

• Good formability

• Good visual effect

• Excellent corrosion resistance

• Excellent weather resistance

• Capability of decoration, molding, corrosion resistance

• Workability, durability

• Excellent heat resistance performance

3.Pre-painted Galvanized/Aluzinc Steel Coil Images

4.Pre-painted Galvanized/Aluzinc Steel Coil Specification

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, any RAL color code.

Paint thickness for back side: (5-10) microns Epoxy

5. FAQ of Pre-painted Galvanized/Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the safety precautions while handling steel coils?

- To prevent accidents and injuries when dealing with steel coils, it is crucial to adhere to specific safety measures. Consider the following key precautions: 1. Personal Protective Equipment (PPE): It is essential to wear suitable PPE, including steel-toed boots, safety glasses, gloves, and a hard hat. This protective gear will safeguard against potential hazards like falling objects, sharp edges, and flying debris. 2. Training and Proper Lifting Techniques: Ensure that workers handling steel coils have received thorough training in safe lifting techniques. This involves lifting with the legs, maintaining a straight back, and avoiding twisting motions. By utilizing proper lifting techniques, the risk of back strains and injuries can be minimized. 3. Secure Storage and Stacking: When storing or stacking steel coils, ensure they are placed on a stable and level surface. Employ appropriate storage equipment like racks or pallets to prevent coils from shifting or falling. Stack the coils securely to prevent toppling or collapsing. 4. Inspection and Maintenance: Regularly inspect steel coils for any defects, such as sharp edges, loose bands, or damaged packaging. Avoid handling coils that appear damaged or unstable. Conduct regular maintenance on equipment like forklifts or cranes used for moving the coils to ensure safe operation. 5. Communication and Signaling: Implement clear communication and signaling protocols among workers involved in handling steel coils. This can involve hand signals or radio communication to coordinate movements and prevent accidents, especially in areas with limited visibility. 6. Load Limits and Capacity: Be aware of the load limits and capacity of the equipment used to move steel coils, such as forklifts or cranes. Overloading equipment can lead to instability, tipping, or collapse, thereby increasing the risk of accidents and injuries. 7. Proper Lashing and Securing: When transporting steel coils, employ appropriate lashing and securing methods to prevent movement or falling during transportation. This may entail using straps, chains, or other restraints to keep the coils securely in place. 8. Emergency Preparedness: Establish an emergency plan in case of accidents or injuries. Ensure that workers are trained in first aid and that emergency response equipment, such as fire extinguishers and first aid kits, are easily accessible. By adhering to these safety precautions, the likelihood of accidents and injuries when handling steel coils can be significantly reduced, creating a safer work environment for all individuals involved.

- Q: How are steel coils used in the production of metal furniture?

- Steel coils are used in the production of metal furniture as the primary raw material for shaping and forming various components such as frames, legs, and supports. These coils are unrolled and cut into appropriate lengths, then undergo processes like bending, welding, and shaping to create the desired furniture pieces. The strength, durability, and malleability of steel make it an ideal material for constructing sturdy and long-lasting metal furniture.

- Q: How are steel coils used in the production of oil and gas machinery?

- Steel coils are used in the production of oil and gas machinery as they provide essential structural support and reinforcement. These coils are typically formed into various components such as pipes, tubes, and casings, which are crucial for drilling, extraction, and transportation processes in the oil and gas industry. The strength and durability of steel coils ensure the reliability and longevity of the machinery, allowing for efficient and safe operations in the oil and gas sector.

- Q: What are the dimensions of a typical steel coil?

- The dimensions of a typical steel coil can vary depending on the manufacturer and specific application, but common dimensions include thicknesses ranging from 0.015 inches to 0.5 inches, widths between 24 inches and 72 inches, and coil weights ranging from a few thousand pounds to over 50,000 pounds.

- Q: What are the different types of steel coil packaging materials for export?

- There are several different types of steel coil packaging materials that are commonly used for export: 1. Steel Strapping: This is one of the most common and widely used materials for packaging steel coils. Steel strapping is strong and durable, providing excellent protection during transportation. It is available in different widths and thicknesses to accommodate different coil sizes. 2. Stretch Film: Stretch film is a flexible and elastic material that is often used to wrap steel coils. It provides a tight and secure packaging, preventing the coils from shifting or falling during transit. Stretch film is also lightweight, which helps to reduce shipping costs. 3. Corrugated Cardboard: Corrugated cardboard is often used as an outer packaging material for steel coils. It provides additional protection against external impacts and acts as a cushioning material. Corrugated cardboard is available in various strengths and sizes to suit different coil dimensions. 4. Wooden Crates: Wooden crates are a popular choice for packing larger steel coils. They provide a sturdy and robust packaging solution, offering excellent protection against impacts, moisture, and other environmental factors. Wooden crates can be customized to fit specific coil sizes and are often used for heavy-duty or long-distance shipments. 5. Plastic Strapping: Plastic strapping is an alternative to steel strapping, especially for lighter coils. It is lightweight, easy to handle, and resistant to rust and corrosion. Plastic strapping is available in different colors, allowing for easy identification and sorting. 6. VCI (Volatile Corrosion Inhibitor) Packaging: VCI packaging materials are used to protect steel coils from corrosion during export. These materials release a vapor that forms a protective layer on the surface of the coils, preventing rust and corrosion even in high humidity or harsh environments. It is important to consider the size, weight, and specific requirements of the steel coils when choosing the appropriate packaging material for export. Additionally, compliance with international shipping regulations and standards should be ensured to guarantee a safe and efficient transportation process.

- Q: What is the average lifespan of a steel coil?

- The average lifespan of a steel coil can vary depending on various factors such as its quality, usage, maintenance, and environmental conditions. However, on average, a well-maintained steel coil can last anywhere from 10 to 30 years.

- Q: Can steel coils be coated with copper?

- Yes, steel coils can be coated with copper. This process, known as copper coating or copper plating, involves applying a thin layer of copper onto the surface of the steel coils to enhance their corrosion resistance, conductivity, and aesthetics.

- Q: How are steel coils used in the petrochemical industry?

- Steel coils are commonly used in the petrochemical industry for various purposes such as manufacturing pipes, tanks, and equipment used in the processing and transportation of petrochemical products. The coils are typically formed into specific shapes and sizes to meet the industry's requirements, ensuring structural integrity and resistance to corrosion. These steel components play a critical role in maintaining the safety and efficiency of petrochemical operations.

- Q: What are the different types of steel coil cutting tools?

- There are several types of steel coil cutting tools, including slitting shears, rotary slitters, flying shears, and laser cutters. Each tool is designed to cut steel coils into specific shapes and dimensions, depending on the desired end product.

- Q: I play the guitar and recently found a new type of a guitar called the steel guitar, I don't want to play it or anything it's just I've never seen anything like it before and wonder what the function of it is and what are the differences to a classical guitar

- Different okorder /. If you just like the sound, take a serious look into slide guitar, not the same, but seriously tasty.

Send your message to us

Pre-painted Galvanized Sheet Coil with Prime Quality and Lowest Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords