Pre-painted Galvanized Sheet Coil with Prime Quality and Lowest Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted Galvanized/Aluzinc Steel Coil Description

Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance.

It generally displays workability, durability and weather resistance.

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel.

2.Main Features of the Pre-painted Galvanized/Aluzinc Steel Coil

• Workability, durability

• Excellent heat resistance performance

• Excellent corrosion resistance • Excellent weather resistance • Capability of decoration, molding, corrosion resistance • High strength

• Good formability

• Good visual effect

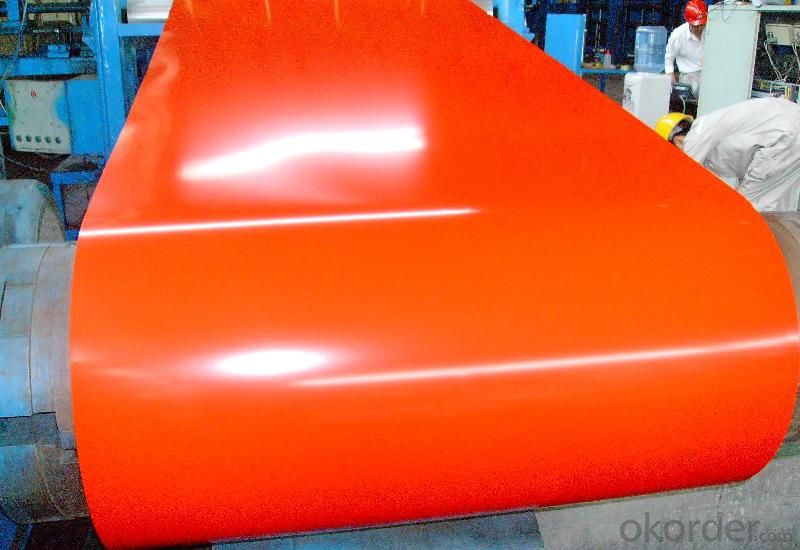

3.Pre-painted Galvanized/Aluzinc Steel Coil Images

4.Pre-painted Galvanized/Aluzinc Steel Coil Specification

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

5. FAQ of Pre-painted Galvanized/Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: What are the common methods of packaging steel coils for transportation?

- There exists a variety of conventional techniques for packaging steel coils for transportation. One frequently employed approach involves the utilization of steel strapping or bands to fasten the coils together. This method entails tightly encircling the coils with steel bands and securing them using metal buckles or seals. The strapping serves to maintain the coils in position and prevent any shifting or rolling during transportation. Another popular technique entails the use of wooden pallets or skids to stack and transport the steel coils. The coils are positioned onto the pallets and secured with steel strapping or bands. This approach ensures stability and facilitates easy handling and loading onto trucks or other means of transportation. Furthermore, certain steel coils are enclosed within wooden crates or boxes. These crates are typically constructed from robust and durable wood and are designed to shield the coils from external impacts or damage during transportation. To enhance strength and stability, the crates are frequently reinforced with steel bands or strapping. In addition to the aforementioned methods, specialized containers or units are employed to package certain steel coils. These containers are specifically engineered to accommodate and secure steel coils for transportation. They often possess integrated mechanisms or features that facilitate the loading and unloading of the coils in a safer and more efficient manner. It is important to acknowledge that the particular method of packaging steel coils for transportation can vary depending on factors such as the size and weight of the coils, the mode of transportation, and any specific requirements or regulations that may be in effect.

- Q: Ok, I have motorcycle classes and im afraid that I wont feel the gear shifter when shifting. So I want to make the boot softer from the toes where the steel is at so i can feel the gear shift with my toes. When i walk and bump into something by accident with my boots I dont feel anything I almost dont notice it. So I think i will be a problem since I wont be able to feel anything.

- You're not from this world, are you?

- Q: Describe and explain how the differences in the properties of the thee main types of steel allow them to be used in different ways. I have some chemistry homework due in for tomorrow (yes I know i left it a bit late but I really don't like chemistry) and I would love it if I could actually at least pretend to my teacher that I know what she's on about this lesson because honestly, I really don't know what she spends so long telling us all. Any help would be appreciated and points for the best answer!

- Hi, Three Main Types of Steel: 1. Carbon Steel Used in making axes, swords, scissors,cutting tools, vehicle frames. Depends on the % of carbon used how soft the steel will be. 2. Stainless Steel Used in the making of crockery, wrist watches, kitchen utensils, cutlery and surgical equipment. Contains different 11% chromium and some % of nickel. 3. Alloy Steel. Used in making drilling parts, vehicle airplane parts. Stainless steel is also alloy steel but, alloy steel with % of other metals is classified separately.

- Q: this is for a school project due morrow can u please answerwhat are disadvantages of stainless steelplease also show were u got info ty

- Disadvantages Of Stainless Steel

- Q: What does "steel roll number" mean?

- The coil numbers in the steel industry are generally applicable to rolled round steel bars. A coil of steel has a specified length and weight. Different rolls have different volumes

- Q: Does anyone know if there is any info on Steel Manufacturing techniques, utilyzing electro/mechanical methods in order to create carbon nanotubes from the %C already inherant in the steel. In other words just modifying the Geometry of the Carbon the already makes up some of the steel.

- I don't think that would work. First off, there's not enough carbon in steel - even very high carbon steels are only about 2% carbon. Second, the iron atoms in steel form a crystal lattice, in the shape of a cube, with another iron atom in the middle of the cube. Each cube is about 0.3 nm per side. Carbon atoms work their way into the crystals and displace the iron atoms. But a carbon nanotube is around 1 nanometer in diameter - that's 3 times as big as the iron lattice! So a nanotube wouldn't fit. One thing you might do, however, is make a composite - mix the materials together on a scale a little bigger than the atomic scale that the iron and carbon mix to make steel. Just like a carbon fiber bicycle frame or ski pole is strands of carbon (much bigger and not as strong as nanotubes) held together with epoxy, you could hold nanotube strands together with metal. Not sure it would be good for armor, but if you can figure out a way to do it, I'm sure someone will come up with a use for it!

- Q: How do steel coils contribute to the construction machinery industry?

- The construction machinery industry relies heavily on steel coils, which are indispensable for the manufacturing of heavy-duty equipment. These coils play a pivotal role in the creation of structural components, such as beams, plates, and tubes, which form the framework of construction machinery. The exceptional strength and durability of steel make it the perfect material for these applications, as it can withstand immense loads and harsh working conditions. Furthermore, steel coils are crucial in the production of various mechanical parts and components used in construction machinery. These include gears, shafts, axles, and hydraulic system components. Steel's versatility allows it to be easily machined and shaped into intricate forms, enabling the production of efficient and reliable machinery parts. In addition to its mechanical properties, steel coils contribute to the construction machinery industry through their resistance to corrosion. Construction machinery is often exposed to moisture, chemicals, and other environmental factors that can lead to rust and deterioration. Steel coils with appropriate coatings or finishes provide an effective safeguard against corrosion, ensuring the longevity and performance of construction machinery. Moreover, the construction machinery industry favors steel coils due to their availability and affordability. Steel is widely manufactured and can be sourced from multiple suppliers, ensuring a consistent supply chain. Its cost-effectiveness compared to alternative materials makes it an attractive choice for manufacturers, enabling them to produce machinery at competitive prices. In conclusion, steel coils are indispensable to the construction machinery industry, offering strength, durability, corrosion resistance, and cost-effectiveness. Their utilization in the fabrication of structural components and mechanical parts guarantees the reliability and efficiency of construction machinery, contributing to the prosperity and advancement of the industry.

- Q: Can steel coils be stored in unheated warehouses?

- Yes, steel coils can be stored in unheated warehouses as long as proper precautions are taken to protect them from moisture, condensation, and extreme temperature fluctuations.

- Q: How do steel coils compare to other materials?

- There are multiple advantages to using steel coils instead of other materials. Firstly, steel is renowned for its strength and durability, which makes steel coils highly resistant to wear and tear. This quality allows them to be used in a wide range of applications. Additionally, steel coils have excellent heat resistance, making them ideal for high-temperature environments. Furthermore, steel coils offer superior corrosion resistance compared to many other materials. This is especially important in industries like construction and automotive, where exposure to moisture and chemicals is common. Steel coils can withstand these harsh conditions, ensuring long-lasting performance and reliability. Another benefit of steel coils is their versatility. Steel can be easily molded into various shapes and sizes, allowing for customization and flexibility in design. As a result, steel coils are suitable for a wide range of applications in manufacturing, construction, transportation, and energy industries. Moreover, steel coils provide good value for money. Despite their numerous benefits, steel coils are generally more affordable than materials like aluminum or copper. This makes steel coils a cost-effective choice for businesses and industries seeking high-quality and reliable materials. In summary, steel coils offer multiple advantages over other materials. They possess high strength, durability, and heat resistance, along with superior corrosion resistance. Steel coils are also versatile and easily customizable for different applications. Additionally, they provide good value for money. Overall, steel coils are a dependable and efficient option for various industries and applications.

- Q: Search the internet for 'Frost Clipper Knife'. This knife comes in either stainless or carbon steel. I have a friend who has one (stainless steel) and he is very impressed with it, but I have heard that Carbon Steel blades are better? Discuss...

- If your talking about a folding pocket knife, I think that it's basically six one way and a half dozen the other. I actually do prefer stainless for my pocket knives. I don't want to oil a knife to the degree I feel carbon requires, only to then stick it my pocket to attract dirt to the knife and oil to my pants. I'm the exact opposite on sheath knives though. I like 1095 carbon steel, plain edge sheath knives. I'll thrash on them HARD, and I rarely have major edge problems. Of course, I require them to be coated with some kind of powder coat or the like, because they can rust, but I do try and keep them clean and dry when in the sheath, so they won't pit the uncoated edge. My reasons for this sheath knife preference is multi-fold. First, these knives are simply affordable. I don't spend $80 dollars on a outdoors sheath knife. I use the tool too hard to want to spend more. I don't like the more traditional stainless steels such as AUS-8, 420HC, and 440C (not to mention the HORRENDOUS 440A) because I feel that the all else being equal, a stainless blade will bend before a carbon blade will break. I also think that carbon holds an edge at least as well, if not better, than traditional stainless, and it's much easier to hone. I don't know much about these new laminates, other than the very hard, but not so tough. They seem to be POSSIBLY too brittle for my use. That, combined with the fact that they cost a FORTUNE, means that I just won't be considering them.

Send your message to us

Pre-painted Galvanized Sheet Coil with Prime Quality and Lowest Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords