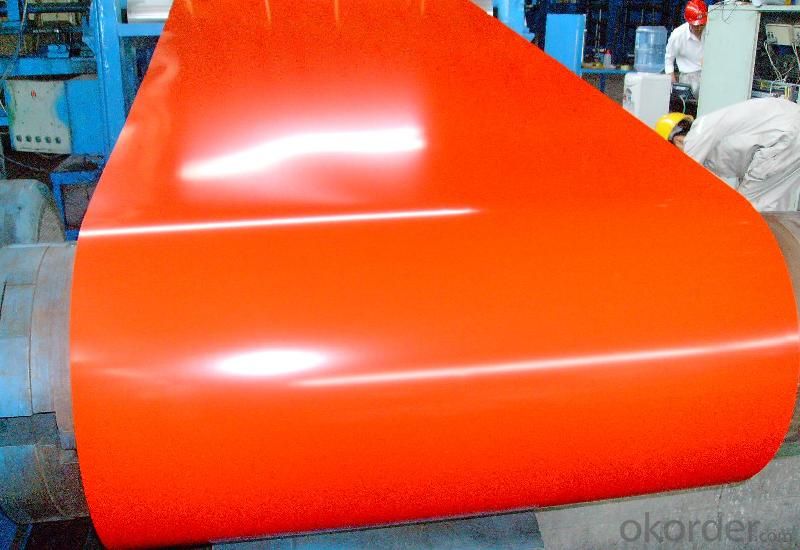

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price Color Orange

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Pre-Painted Galvanized/Aluzinc Steel Coil Description:

Pre-painted Galvanized/Aluzinc Steel Coil with GI or Aluzinc as base metal,after pretreatment,

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil

• High strength

• Good capable of decoration

3.Detail Images of Pre-Painted Galvanized Steel Coil

4.Quick Details of the Pre-Painted Galvanized/Aluzinc Steel Coil

Standard | ASTM ,EN,JIS | Grade: | CS,DX51D+Z,CGCC | Thickness | 0.16mm-1.5mm |

Place of Origin | China(Mainland) | Brand Name | Type | Steel Coil | |

Technique | Galvanized/Aluzinc | Surface | Coated | Application | Roof panel |

Width | 900mm-1250mm | Length | Coils | Zinc Coating | 30g/m2-275g/m2 |

5.Specification of PPGI / GI Steel Sheet/Coil

1) AVAILABLE DESIGNATION OF PPGI/PPGL Prepainted Galvanized/Galvalume Steel Coils

Quality | Q/BQB 440-2003 | JIS G3312-1994 | EN 10326-2004 | ASTM A653-02a |

EN 10327-2004 | (BASE PLATE) | |||

(BASE PLATE) | ||||

Commercial Steel | TDC51D | CGCC | DX51D+Z/AZ | CS Type A/B/C |

Forming Steel | (TSt01,TSt02,TSt03) | CGCD1 | FS Type A, Type B | |

Drawing | TDC52D /TDC53D | - | DX52D+Z/AZ | DDS TYPE A/C |

Steel | DX53D+Z/AZ | |||

Structural | TS280GD(TStE28) | CGC400 | S280D+Z/AZ | SS275 |

3) APPLICATION OF PPGI/PPGL (Prepainted Galvanized/GalvalumeSteel Coils)

Construction | Outside | Workshop, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth |

Inside | Door, doorcase, light steel roof structure, folding screen, elevator, stairway, vent gutter | |

Electrical appliance | Refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker | |

Furniture | Central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf | |

Carrying trade | Exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board | |

Others | Writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment | |

6.FAQ

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

- Q: I was looking at my Great-Grandfather's immigration form from when he immigrated from Scotland and he listed his occupation as a steel dresser. What does a steel dresser do?

- The steel dresser was a person who would clean the freshly made cast steel pieces at a foundry/ steel factory. Usually when the steel comes out it will have some extra bits and pieces sticking out that need to be removed. The steel is melted and cast into shape so there will be like a little raised line where edges of the mold met or a few blobs sticking out where the hot steel dripped over the edge or something. The dresser was the person who got rid of that kind of stuff to make a more finished/even product.

- Q: I got my dog those nice looking stainless steel water and food bowls (looks great next to my kitchen appliances...haha). The thing is my dog will drink from the toilet or a plastic bowl but not out of his bowl...I was wondering if those stainless steel bowls change the taste of food and water?

- It is possible. Stainless steel is usually mixed with a few other metal compounds to create certain properties for it, like iron for durability, and nickel and silver for luster(so they look good in your house!). It is very possible that your dog is tasting some of those metals in his water, and since his senses are a lot keener tan ours, it may bother him. My dogs drink out of a stainless steel bowl, and they do fine, so it may be your dog's own personal preference to drink out of someting non-metal. Just give in to him and give him a nice-looking plastic or ceramic bowl. (Hint: Ceramic keeps his water cold longer!)

- Q: Are Danielle steel books good to read. Im 15 , but do I have to wait until Im a bit older.

- No they are a good read.

- Q: i have a guitar with three nylon three steel strings. Am i able to replace the nylons with steel strings?

- earlier you circulate approximately any extensive alterations, take the guitar to a qualified technician and notice approximately having the strings, or action diminished nearer to the fretboard. this could take very numerous soreness off of his palms, because it feels like the guitar hasn't been set-up in any respect, or a minimum of superb. A neck adjustment, if mandatory, might additionally help this issue. If he continues to be experiencing finger soreness (he might might desire to undergo some), attempt a lighter gauge set of strings (steel). a good tech can help you there, too. Nylon strings are not going to paintings properly in any respect on a non-classical guitar; the parameters are in basic terms different adequate between the two certainly one of them to end not something greater suitable than to waste your money. the main uncomplicated issue I see on a conventional foundation is that guitars are offered and offered without suitable set-up. An experienced tech will examine the neck configuration; the bridge alignment; saddle top; venture end; nut clearance; and action on an acoustic guitar. There are much greater info on an electric powered. Please detect a music/guitar save that does this form of paintings on the premises. My concept is that the finished relatives will income. Cheers decrease back atcha!

- Q: is stainless steel a good steel for sensitive skin? or does it have to be surgical or sterling silver?

- idk about sensitive skin but i have stainless steal in i think right now. im sure any are good for a healed belly piercing, if it hasnt been 3 monthes yet then id stick with a surgical

- Q: How are steel coils loaded onto trucks or containers?

- Steel coils are typically loaded onto trucks or containers using specialized equipment such as cranes, forklifts, or coil trailers. The coils are lifted and secured onto the truck or container using straps, chains, or clamps to ensure safe transportation.

- Q: I bought a stainless steel water bottle today. I really like it, but there is no drinking spout, it just has a lid that screws on and off, and an open hole to fill it and drink out of. Is this normal for these bottles? Or do they usually come with a spout to drink from? I don't want to look like an idiot at the gym drinking from this cool bottle with no spout if there's supposed to be one! haha.

- If okorder /...

- Q: What are the different types of steel coil transport methods?

- There are several different types of steel coil transport methods, including flatbed trucks, specialized coil trailers, rail transport, and shipping containers.

- Q: What is the average lead time for receiving replacement steel coils?

- The average lead time for receiving replacement steel coils can vary depending on various factors such as the supplier, location, and specific requirements. It is recommended to consult with the supplier or manufacturer directly to get an accurate estimate of the average lead time for receiving replacement steel coils.

- Q: i heard steel type is good and i don't have any i have defeated all the trainers up to the icicle badge (i have got the icicle badge but not the one after) where can i get one?

- you can get a steelix at the cave just before the elite four. but if you have wifi, you can trade for one.

Send your message to us

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price Color Orange

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords