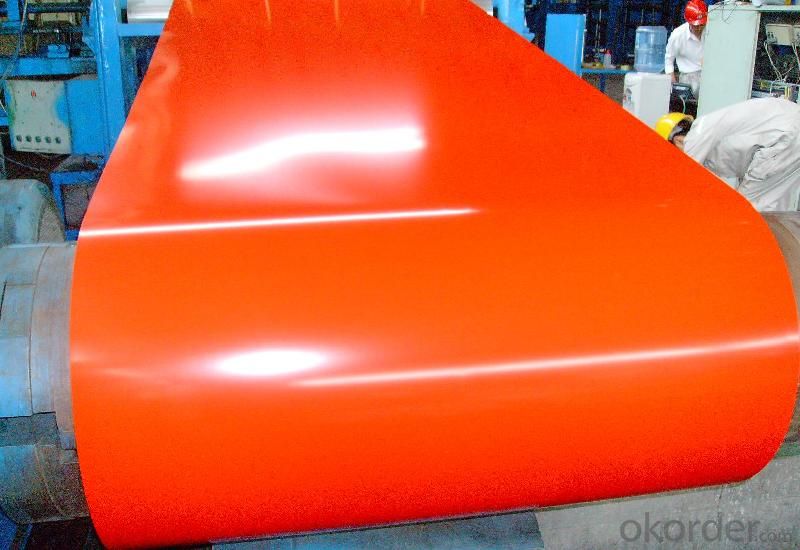

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality with Orange Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Pre-Painted Galvanized/Aluzinc Steel Coil Description:

Pre-painted Galvanized/Aluzinc Steel Coil with GI or Aluzinc as base metal,after pretreatment,degrease , chemical treatment and liquid dope with several layers of color ,then after fring and cooling ,2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil

• High strength

• Good capable of decoration

• Superior workability

• Good visual effect

3.Detail Images of Pre-Painted Galvanized Steel Coil

4.Quick Details of the Pre-Painted Galvanized/Aluzinc Steel Coil

Standard | ASTM ,EN,JIS | Grade: | CS,DX51D+Z,CGCC | Thickness | 0.16mm-1.5mm |

Place of Origin | China(Mainland) | Brand Name | Type | Steel Coil | |

Technique | Galvanized/Aluzinc | Surface | Coated | Application | Roof panel |

Width | 900mm-1250mm | Length | Coils | Zinc Coating | 30g/m2-275g/m2 |

Paint | Standard PE,PVDF,PU | Color | RAL Scale | Coil Weight | 3mt-7mt |

5.Specification of PPGI / GI Steel Sheet/Coil

1) AVAILABLE DESIGNATION OF PPGI/PPGL Prepainted Galvanized/Galvalume Steel Coils

Quality | Q/BQB 440-2003 | JIS G3312-1994 | EN 10326-2004 | ASTM A653-02a |

EN 10327-2004 | (BASE PLATE) | |||

(BASE PLATE) | ||||

Commercial Steel | TDC51D | CGCC | DX51D+Z/AZ | CS Type A/B/C |

Forming Steel | (TSt01,TSt02,TSt03) | CGCD1 | FS Type A, Type B | |

Drawing | TDC52D /TDC53D | - | DX52D+Z/AZ | DDS TYPE A/C |

Steel | DX53D+Z/AZ | |||

Structural | TS280GD(TStE28) | CGC400 | S280D+Z/AZ | SS275 |

Steel | TS350GD(TStE34) | CGC440 | S350D+Z/AZ | SS340 Class1 |

2) OUR SPECIFICATION OFPPGI/PPGL (Prepainted Galvanized/GalvalumeSteel Coils)

Thickness | Width | Length of plate | Inner diameter of coil | |

0.16-1.2mm | 800/914/1000/1200/1219/1250mm | 1000-6000mm | 508mm/610mm |

Coated Mass OF PPGI/PPGL (Prepainted Galvanized/GalvalumeSteel Coils) :

Base plate | Available Coated Mass(g/m^2) |

Galvanized Steel | 30,80, 100, 120, 160, 180, 200, 275 |

Galvalume Steel | 30,50, 70, 150 ect. |

Available Painting OF PPGI/PPGL (Prepainted Galvanized/GalvalumeSteel Coils) :

Category of Painting | Item | Code | |

Polyester | PE | ||

High-durability polyester | HDP | ||

Silicon modified polyesters | SMP | ||

Polyvinylidene fluoride | PVDF | ||

Easy-Cleaning | — | ||

Painting Thickness | Top side: 5+20microns; | ||

Bottom side: 5~7microns. | |||

Color System | Produce according to RAL Color System or as per buyer’s color sample. | ||

Painting structure | Top surface | Bottom surface | |

Primer coating | No coating | 1/0 | |

Primer coating | Primer coating | 1/1 | |

Primer coating + Finish coating | No coating | 2/0 | |

Primer coating + Finish coating | Primer coating or single back coating | 2/1 | |

Primer coating + Finish coating | Primer coating + Finish back coating | 2/2 | |

Note: Protect film available

5.FAQ

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the common surface defects found in steel coils?

- Some common surface defects found in steel coils include rust, scratches, dents, pits, and mill scale.

- Q: Ok, I have motorcycle classes and im afraid that I wont feel the gear shifter when shifting. So I want to make the boot softer from the toes where the steel is at so i can feel the gear shift with my toes. When i walk and bump into something by accident with my boots I dont feel anything I almost dont notice it. So I think i will be a problem since I wont be able to feel anything.

- sorry you cant

- Q: How are steel coils used in the manufacturing of agricultural machinery?

- Steel coils are used in the manufacturing of agricultural machinery as they provide the necessary strength and durability required for various components such as frames, axles, and blades. These coils are shaped, cut, and welded to form the desired parts, ensuring the machinery can withstand the demanding conditions of agricultural operations.

- Q: How are steel coils used in the production of agricultural equipment?

- Steel coils are used in the production of agricultural equipment as they serve as the primary material for manufacturing various components such as frames, brackets, and structural supports. These coils are shaped, cut, and welded to create the required parts, which are then assembled to form agricultural machinery like tractors, plows, and harvesters. The strength and durability of steel make it an ideal choice for withstanding the demanding conditions and heavy workloads typically associated with agricultural equipment.

- Q: How do steel coils contribute to the energy infrastructure sector?

- Steel coils contribute to the energy infrastructure sector by serving as a crucial component in the construction and maintenance of power plants, oil and gas pipelines, and electrical transmission systems. These coils are used to manufacture various equipment and structures, such as turbines, generators, transformers, and transmission towers. Additionally, steel coils provide strength, durability, and corrosion resistance, ensuring the longevity and reliability of the energy infrastructure, ultimately supporting the efficient and uninterrupted supply of electricity, oil, and gas to meet the growing energy demands.

- Q: What is the cost of steel coils?

- The cost of steel coils can vary depending on factors such as size, quality, and market conditions. It is best to contact a supplier or check current market prices to get an accurate cost.

- Q: Why is the selection of steel building erector of extreme importance while starting a new steel building project?

- Steel building erectors play an important role as they are well versed with all the ups and downs of erecting a steel building and can prevent your construction project from unnecessary delays. There are lot of inexperienced steel building erectors in the market who can offer you their services at a much cheaper rate. Be cautious! It never works in the long run. A qualified steel building erector will always provide an initial professional insight of your project and cost effective solutions for your project.

- Q: How are steel coils used in the automotive industry?

- Steel coils are used in the automotive industry to manufacture various components such as car bodies, frames, and structural parts. The coils are first processed by being uncoiled, flattened, and then cut into the required shapes. These steel components provide strength, durability, and rigidity to vehicles, ensuring safety and structural integrity.

- Q: How are steel coils used in the production of kitchenware?

- Steel coils are used in the production of kitchenware as they serve as the primary material for manufacturing various items like pots, pans, and utensils. The coils are typically cut and shaped into the desired form before being further processed through various techniques such as stamping, welding, and polishing. These processes help create durable and heat-resistant kitchenware that is essential for cooking and food preparation.

- Q: How are steel coils used in the manufacturing of transmission shafts?

- Steel coils are used in the manufacturing of transmission shafts by being formed into cylindrical shapes and then machined to create the desired dimensions and features of the shaft. The steel coil is typically cut to the required length and then undergoes a series of manufacturing processes, such as forging, heat treatment, and machining, to produce a strong and durable transmission shaft.

Send your message to us

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality with Orange Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords