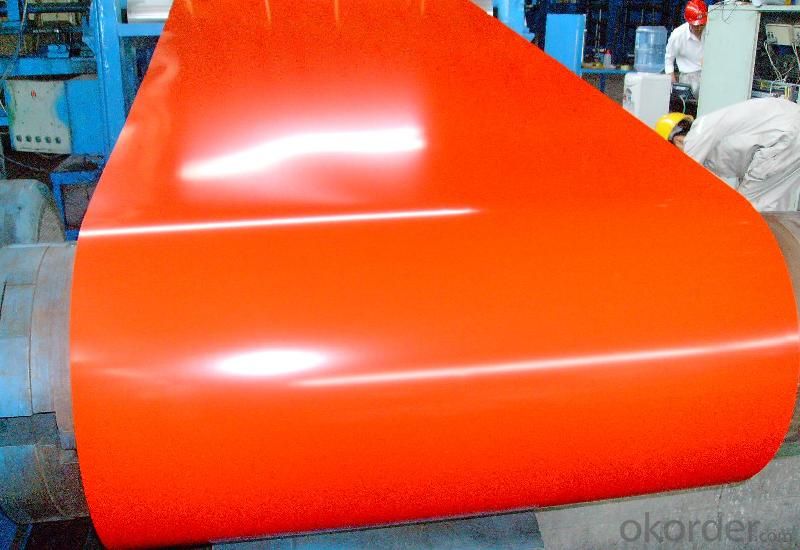

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price orange

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Pre-Painted Galvanized/Aluzinc Steel Coil Description:

Pre-painted Galvanized/Aluzinc Steel Coil

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil

• High strength

• Good capable

3.Detail Images of Pre-Painted Galvanized Steel Coil

4.Quick Details of the Pre-Painted Galvanized/Aluzinc Steel Coil

Standard | ASTM ,EN,JIS | Grade: | CS,DX51D+Z,CGCC | Thickness | 0.16mm-1.5mm |

Place of Origin | China(Mainland) | Brand Name | Type | Steel Coil | |

Technique | Galvanized/Aluzinc | Surface | Coated | Application | Roof panel |

Width | 900mm-1250mm | Length | Coils | Zinc Coating | 30g/m2-275g/m2 |

5.Specification of PPGI / GI Steel Sheet/Coil

1) AVAILABLE DESIGNATION OF PPGI/PPGL Prepainted Galvanized/Galvalume Steel Coils

Quality | Q/BQB 440-2003 | JIS G3312-1994 | EN 10326-2004 | ASTM A653-02a |

EN 10327-2004 | (BASE PLATE) | |||

(BASE PLATE) | ||||

Commercial Steel | TDC51D | CGCC | DX51D+Z/AZ | CS Type A/B/C |

Forming Steel | (TSt01,TSt02,TSt03) | CGCD1 | FS Type A, Type B | |

Drawing | TDC52D /TDC53D | - | DX52D+Z/AZ | DDS TYPE A/C |

Steel | DX53D+Z/AZ | |||

Structural | TS280GD(TStE28) | CGC400 | S280D+Z/AZ | SS275 |

Construction | Outside | Workshop, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth |

Inside | Door, doorcase, light steel roof structure, folding screen, elevator, stairway, vent gutter | |

Electrical appliance | Refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker | |

Furniture | Central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf | |

Carrying trade | Exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board | |

Others | Writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment | |

6.FAQ

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

- Q: How are steel coils used in the manufacturing of industrial filters?

- Steel coils are used in the manufacturing of industrial filters as a primary material for constructing the filter frames and support structures. The coils are typically cut, shaped, and welded to create the necessary framework that holds the filter media and allows for efficient filtration. The strength and durability of steel make it an ideal choice for withstanding the pressure and demands of industrial filtration processes.

- Q: What are the different types of steel coil surface coatings?

- Steel coils can be enhanced in terms of durability, corrosion resistance, and aesthetic appearance through the use of various types of surface coatings. The most commonly employed coatings are as follows: 1. Zinc Coatings: These are widely utilized to safeguard steel against corrosion. A layer of zinc is applied to galvanized steel coils, acting as a barrier against moisture and other environmental elements. 2. Galvannealed Coatings: This type of coating combines zinc and iron, providing improved corrosion resistance and enhancing paint adhesion. It is ideal for applications that require painting. 3. Aluminum Coatings: Aluminum coatings are employed to achieve a lightweight and corrosion-resistant surface. Steel coils coated with aluminum are frequently utilized in the automotive industry for body panels and other parts that require high strength and corrosion resistance. 4. Organic Coatings: Organic coatings, typically in the form of paint or powder coatings, offer protection against corrosion. They also provide a wide range of color options for aesthetic purposes. In the construction industry, they are commonly used for roofing and cladding applications. 5. Metallic Coatings: Metallic coatings such as tin, nickel, and chromium can be applied to steel coils to confer specific properties, such as improved electrical conductivity, increased hardness, or enhanced resistance to wear and tear. 6. Ceramic Coatings: Ceramic coatings are employed to achieve high-temperature resistance and thermal barrier properties. They find application in situations where steel coils are exposed to extreme heat or in industrial processes that require thermal insulation. Each type of coating possesses unique properties and advantages, and the selection of a suitable coating depends on the specific requirements of the application. Manufacturers and engineers carefully consider factors such as cost, durability, corrosion resistance, and aesthetic appeal when deciding on the appropriate coating for steel coils.

- Q: How do steel coils contribute to the manufacturing of agricultural machinery?

- The manufacturing of agricultural machinery heavily relies on steel coils, which play a vital role in this process. Typically, these coils are crafted from top-notch steel that possesses exceptional strength, durability, and resistance to corrosion. To begin with, agricultural machinery heavily relies on steel coils for the construction of its main structural components, including the chassis, frames, and supports. These components must endure heavy loads, extreme weather conditions, and rough terrains. Thanks to the strength and resilience of steel coils, the machinery can effectively handle these challenging environments and operate efficiently. In addition, steel coils find application in the production of various moving parts and mechanisms within agricultural machinery. For example, gears, shafts, and axles, which are crucial for power transmission and rotational motion transformation, are created using steel coils. The high tensile strength and excellent machinability of steel make it an ideal material for these essential components, ensuring their reliability and longevity. Moreover, steel coils contribute to the manufacturing of agricultural machinery by providing a protective layer against wear and tear. Often, these coils are coated with specialized finishes or paints to enhance their resistance to rust, chemicals, and abrasion. This protective layer significantly prolongs the machinery's lifespan, reduces the need for frequent maintenance and repairs, and ultimately increases its overall efficiency and productivity. Furthermore, the versatility of steel coils allows for customization and adaptation to meet the specific requirements of agricultural machinery. Manufacturers can shape and mold the coils into different sizes and dimensions, enabling the production of machinery suitable for various farming practices and applications. Whether it's tractors, harvesters, or irrigation systems, steel coils are crucial for creating versatile and dependable agricultural machinery. In conclusion, steel coils are essential in the manufacturing of agricultural machinery due to their strength, durability, resistance to corrosion, and customization capabilities. From structural components to moving parts and protective coatings, steel coils greatly contribute to the efficiency, reliability, and longevity of agricultural machinery, thus providing significant support to the global agricultural industry.

- Q: basically all the info you can find about s1 tool steel i found a bunch about annealing, and hardening, tinsel strength and stuff like that but i need MORE!!!!!

- * okorder /

- Q: What are the different types of steel coil finishes used in architectural applications?

- There are several different types of steel coil finishes that are commonly used in architectural applications. These finishes are applied to steel coils to enhance their appearance and provide additional protection against corrosion and weathering. Some of the most popular types of steel coil finishes used in architectural applications include: 1. Mill Finish: This is the most basic type of steel coil finish, where the coil is left untreated after being rolled. It has a dull, gray appearance and is often used in industrial and structural applications where aesthetics are not a primary concern. 2. Hot-Dip Galvanized: In this finish, the steel coil is immersed in a bath of molten zinc, which creates a thick layer of zinc coating on the surface. This finish provides excellent corrosion resistance and is commonly used in outdoor architectural applications such as roofing, gutters, and siding. 3. Galvalume: This finish is similar to hot-dip galvanized, but instead of pure zinc, it uses a combination of zinc and aluminum. Galvalume-coated steel coils offer superior corrosion resistance and are often used in high-end architectural applications, such as metal roofing and wall panels. 4. Pre-Painted: In this finish, a layer of paint is applied to the steel coil before it is shipped to the customer. This allows for a wide range of colors and finishes to be achieved, making it a popular choice for architectural applications where aesthetics are important. Pre-painted steel coils are commonly used in exterior cladding, garage doors, and decorative panels. 5. Stainless Steel: This finish is achieved by using a steel alloy that contains a high percentage of chromium. Stainless steel coils have excellent corrosion resistance and are often used in architectural applications where a clean, modern look is desired, such as handrails, elevator interiors, and kitchen appliances. Each type of steel coil finish offers unique advantages and is suitable for different architectural applications. The choice of finish depends on factors such as the desired appearance, level of corrosion resistance required, and the specific environmental conditions the steel will be exposed to.

- Q: How are steel coils used in the production of scaffolding?

- Steel coils are used in the production of scaffolding as they are typically cut and shaped into various components such as tubes, frames, and brackets. These coils provide the necessary strength and durability required for scaffolding structures, ensuring the safety and stability of workers who use them.

- Q: I play the guitar and recently found a new type of a guitar called the steel guitar, I don't want to play it or anything it's just I've never seen anything like it before and wonder what the function of it is and what are the differences to a classical guitar

- There okorder /

- Q: what do they use to make stainless steel?and can stainless steel be melted again and again without losing it's Specifications

- The stainless steel is a family of ferrous alloys containing at least 11% chromium. The effect of this amount of chromium in steel in reducing corrosion is dramatic. There are many grades of stainless steels. By varying the chemical composition, heat treating, and cold-working, a wide range of properties is achieved. There are three types of precipitation hardening stainless steels: *martensitic types, which are supplies in the martensitic condition, are hardened by a simple aging treatment of the fabricated part. *Semi austenitic types, which are supplied in the austenitic condition, are transformed to martensite by special heat treatment before precipitation hardening. *the austenite in the austenitic types is precipitation hardened directly. The heat treatments of precipitation-hardening stainless steels are chosen to optimize mechanical properties. Precipitation hardening generally results in a slight increase in corrosion susceptibility and an increased susceptibility to hydrogen embrittlement.

- Q: Hey guys do you know anything about Steel Arch Building and how this structure really looks like?

- Steel Arch buildings consist of arched steel panes and can be erected very easily in minimal time. Steel Arch buildings can be used for both agricultural and industrial purposes. They come in the shape of an arch which serves the dual purpose of both the roof and the wall. after constructing it you can get 100% useable clear span space! No poles, beams or trusses are required for it. We can call it do-it-yourself construction cause most buildings are erected in just a few days with help from family or friends.

- Q: I want to get one of these knives but I am having trouble deciding which is the best overall knife??ThanksSOG Trident tigerSOG Vulcan TantoSOG Bi-Polar (Serrated)Cold Steel ScimitarCold Steel Recon 1

- Look up a knife maker called Bench Made, the knife i recommend is the CQC7 its a tanto tip half serrated blade all low glare black folding with pocket clip. it has one of the hardest steel blades. You need to learn about steel hardness the harder the blade the sharper it can get and the harder the longer it will hold a edge. but hard steel can get brittle it can snap now as softer steel will bend and dull quick. the bench-made CQC7 goes for around $100 or that ball park...enjoy read some about the knife and think about what you want it for....my CQC7 can cut a coat hanger by pulling the serrate across the hanger!!

Send your message to us

Pre-painted Galvanized/Aluzinc Steel Sheet Coil with Prime Quality and Lowest Price orange

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords