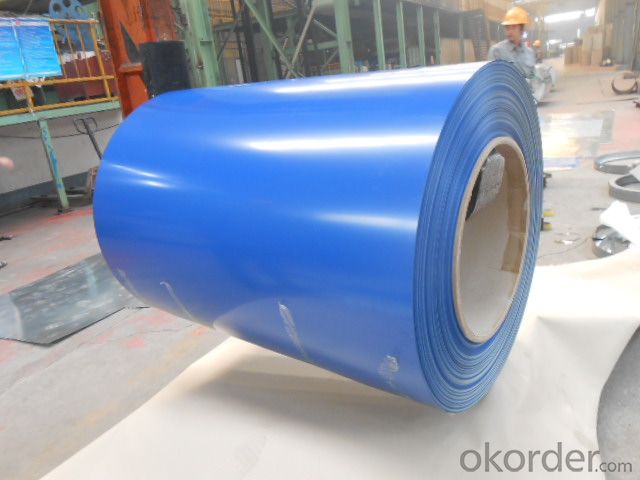

Pre-Painted Galvanized Steel Sheet/Coil ,Prime Quality Blue Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: What are the different types of steel coil processing equipment?

- There are several different types of steel coil processing equipment, including coil slitting machines, coil cut-to-length machines, coil leveling machines, and coil edge trimming machines. Each of these machines serves a specific purpose in the steel coil processing industry, helping to efficiently and accurately cut, shape, and prepare steel coils for various applications.

- Q: why were guns, germs and steel absent within America?

- i dont really understand this question but if it means to how it was before then it was absent because the native americans were not into technology so they obviously had no guns created that was something that they had traded to get from europe as for the germs i ddo not know about thta really except for if it means that common disease and one of the diseases most used in history books is malaysa from mosquitos but when they had traded with europe they got all sorts of diseases now for steel the only reason i remember them traveling for is for gold and i dont remember them ever looking for it until 13 colonies were established as you can see im not exactly sure about germs and steels but i know that the guns part is correct

- Q: where can i get a thick sheet of steel ? and is steel bullet proff for example if you shoot a bullet on steel will that bullet bounce right off the steel ?

- Try the business-to-business yellow pages in your area. A local hardware store can also tell you who to contact. Or search steel plate or sheet metal on the internet to find a local supplier. No, sheet steel is not bullet proof, unless you get heavy plate. Depending on how thick it is, the plate will deform if hit by a high velocity bullet, but usually not enough to matter. Bullets have velocities from about 500 ft/sec up to roughly 3000 ft/sec, depending on the type of weapon used. I wouldn't try to use anything thinner than 3/4 inch. You'll have to experiment and see what it will actually stop. I can't guarantee it'll stop a high-velocity rifle slug. Try it and see.

- Q: Can steel coils be bent or shaped?

- Yes, steel coils can be bent or shaped due to their flexibility and malleability.

- Q: How can steel coils be recycled?

- Steel coils can be recycled by first removing any contaminants or coatings from the surface. The coils are then shredded into smaller pieces and melted in a furnace. The molten steel is then formed into new coils or other steel products.

- Q: How are steel coils used in the production of rail tracks?

- Steel coils are used in the production of rail tracks as they are a primary raw material for manufacturing the rails. These coils are first processed to form the desired shape and dimensions of the rail tracks, which are then cut, welded, and shaped to create the individual rail sections. The steel coils provide the strength, durability, and flexibility necessary for the tracks to withstand heavy loads, extreme weather conditions, and constant use.

- Q: How are steel coils inspected for elongation?

- Steel coils are typically inspected for elongation by conducting a tensile test. A small sample is cut from the coil and subjected to tension until it breaks. The elongation is then calculated by measuring the increase in length of the sample at the point of fracture.

- Q: How are steel coils used in the manufacturing of crash structures?

- Steel coils are used in the manufacturing of crash structures as they provide strength, durability, and energy absorption capabilities. These coils are typically formed into various shapes and sizes to create components that reinforce the vehicle's body, such as side impact beams or front and rear crumple zones. The steel coils absorb and distribute the impact energy during a crash, helping to protect the occupants by minimizing the force transferred to the passenger compartment.

- Q: What are the common surface treatments for galvanized steel coils?

- Galvanized steel coils can undergo various surface treatments to improve their corrosion resistance and appearance. Passivation is one such treatment, where a protective material like zinc phosphate or chromate is applied to create a barrier against moisture and atmospheric elements. This also enhances the adhesion of subsequent coatings or paints. Another treatment is chromate coating, which involves applying a thin layer of chromate to the steel surface. This provides extra protection against corrosion and enhances the steel's appearance. Chromate coatings can be clear or colored, depending on the desired aesthetic. Oiling is a common treatment that involves applying a thin layer of oil to prevent rust and corrosion during storage and transportation. It also offers temporary protection against moisture and other environmental factors until the steel is further processed or used. These surface treatments are widely used to improve the performance, durability, and appearance of galvanized steel coils, ensuring they can withstand harsh conditions and maintain their quality over time.

- Q: What are the common coil coating materials?

- The common coil coating materials include polyester, polyurethane, polyvinylidene fluoride (PVDF), silicone polyester, and epoxy.

Send your message to us

Pre-Painted Galvanized Steel Sheet/Coil ,Prime Quality Blue Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords