Pre-painted Galvanized Steel Sheet Coil with Prime Quality and Best Price, Blue Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted Galvanized/Aluzinc Steel Coil Description

With GI (aluzinc) as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays workability, durability and weather resistance.

2.Main Features of the Pre-painted Galvanized/Aluzinc Steel Coil

• Excellent corrosion resistance

• Excellent weather resistance

• Capability of decoration, molding, corrosion resistance

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-painted Galvanized/Aluzinc Steel Coil Images

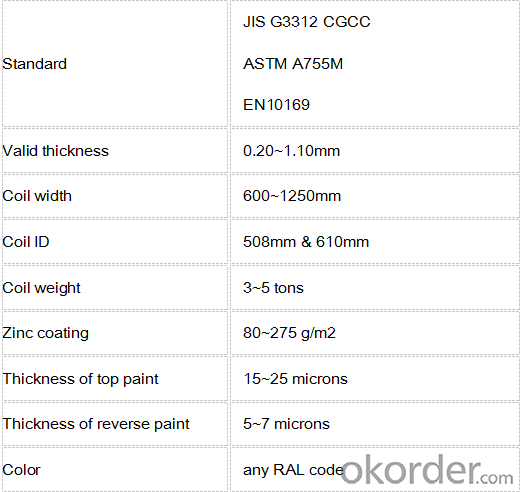

4.Pre-painted Galvanized/Aluzinc Steel Coil Specification

Quality standar: JIS G3312 CGCC & CGLCC

Hardness of P: Both soft and hard quality are available

Surface finish: with or without protect film

Thickness : 0.14-1.20 mm

Width : 914mm, 1000mm, 1220mm and 1250mm, thickness 600-1250mm is available

Finish by coil or sheet: Both sheet and coil are available

8Zinc coating: 60-275G/M2, both sides

Paint thickness for top side : 5 micron primer + (10-20) microns modified polyester, any RAL color code.

Paint thickness for back side: (5-10) microns Epoxy

Weight per coil: 4-6 tons, also can be upon customer's requirements

Max loading weight in one 20ft container : 25 tons generally

5. FAQ of Pre-painted Galvanized/Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What is the yield strength of steel coils?

- The yield strength of steel coils can vary depending on the specific grade and composition of the steel. However, the typical yield strength of steel coils ranges from 300 to 600 megapascals (MPa).

- Q: 420 440 1045 or 1065 ive bought knifes with these steel grades and i want to know which one is better.

- SAE 440 is the best. Classified as high grade cutlery steel. There are various grades of 440: A, B, C, and F. 440 A is the most stain resistant while 440 C has the most carbon and can achieve the highest hardness (Best edge Retention). SAE 440 Chemistry: 16 - 18% Chromium, 0.60 - 1.2% Carbon, 0.75% Molybdenum. SAE 420 is pretty good. Classified as cutlery steel, it is a stain resistant grade but has less chromium and significantly less carbon than SAE 440. SAE 420 Chemistry: 12 - 14% Chromium, 0.15% Carbon (min), 0 Molybdenum Chromium is what makes the steel corrosion resistant. It also adds toughness. Molybdenum adds extra corrosion resistance and adds hardenability. So you can see by chemical components that 440 is highest quality although that also means more cost. 1045 and 1065 are low quality steels and you should probably never use them for a knife. The 1 indicates plain carbon steel with little other alloying elements. The last two digits indicate how much carbon is in the steel. 1045 has 0.45% carbon, mid-range hardenability. 1065 has 0.65% carbon, high hardenability. So if I had to choose I would choose 1065 over 1045 but the difference isn't that noticeable. Everything I said here assumes they have all had the optimum Quench and Temper heat-treatment for their chemistry grade.

- Q: What are the common manufacturing defects in steel coils?

- There are several common manufacturing defects that can occur in steel coils, including surface imperfections such as scratches, pits, or dents, dimensional inconsistencies such as uneven thickness or width, edge defects like burrs or cracks, and internal defects such as inclusions or voids. These defects can impact the quality and performance of the steel coils, and manufacturers strive to minimize these issues through quality control measures and inspections.

- Q: What are the dimensions of steel coils used in the storage system industry?

- The dimensions of steel coils used in the storage system industry can vary depending on the specific requirements and applications. However, there are some common dimensions that are widely used. The most common coil width ranges from 600mm to 2000mm, although it can be as narrow as 100mm or as wide as 2500mm in certain cases. The coil thickness typically ranges from 0.5mm to 6mm, but it can go up to 25mm for specialized applications. The inner diameter of the coil, known as the core diameter, is usually between 508mm and 610mm. The weight of steel coils can vary significantly depending on the width, thickness, and length of the coil. However, a standard steel coil can weigh anywhere from 3 to 20 tons. It is important to note that these dimensions are not fixed and can be customized based on the specific storage system requirements and the industry in which they are used.

- Q: My 8-year-old and 9-year-old boys have approached me with an interesting question. Does fire burn steel? One says yes, the other says no. Help me to settle yet another debate :)

- no, fire MIGHT cause steel to oxidize, depending on the alloy, but think of steel as a block of ice. Steel melts at 2800 degrees F and boils and evaporates at 5400 degrees. Some metals like magnesium can possibly catch fire but not steel

- Q: I have a Charles Daly shotgun and I'm trying to find out if it is ok to shoot steel out of. The side engravings say: Charles Daly 20 GA 3 and the other side says : KBI-HBG, PA made in TurkeyOn their website it says that the barrel on the Charles Daly 300 Field is able to shoot steel but I don't see anywhere that this is a 300 model.Im also not sure if the choke is able to shoot steel. It has no engravings on it. How can I tell if this choke will work? It is the original choke that came with the gun?

- It's fine. Like .700 Nitro said, lead is a softer metal than steel. . BTW- Tom, grow up. I doubt you have ever been hunting in your life. What the he!! does someone's S.S number have to do with hunting? Nothing jack $$. Here's some advice for you- follow me around for a few days down here... It will cost you a little bit more than $15 per hour. Down here, a guy will actually realize that he as family jewels.

- Q: What are the dimensions of steel coils used in automotive part manufacturing?

- The dimensions of steel coils utilized in the manufacturing of automotive parts may differ based on the particular application and manufacturer involved. Nonetheless, typical dimensions for steel coils in automotive part production lie within the range of 0.5 to 3 millimeters in thickness and 600 to 2000 millimeters in width. Additionally, the length of the coils can vary considerably, generally spanning from a few meters to several hundred meters. It is crucial to acknowledge that these dimensions are not set in stone and can be tailored to satisfy the specific demands of each automotive part being produced.

- Q: Can we construct a barn using steel and will it be a durable one?

- Steel barns in the USA is the going fad; they are both strong and economical; and some companies offer DIY kits

- Q: What are the different methods of edge wave correction for steel coils?

- There are several methods commonly used to correct edge waves in steel coils. These methods aim to eliminate or minimize the occurrence of edge waves, which are deformations that can occur along the edges of steel coils during processing or handling. One of the most common methods is called edge wave flattening. This technique involves using hydraulic or mechanical devices to apply pressure to the edges of the coil, effectively flattening out any waves or deformations. This can be done during the coil processing stage or as a separate step after the coil has been produced. Another method is known as edge trimming. In this approach, the edges of the coil are trimmed or cut to remove any waves or deformations. This can be done through mechanical shearing or using laser cutting technology. Edge trimming not only corrects the edge waves but also ensures that the coil has straight and smooth edges. Additionally, tension leveling is another popular method for edge wave correction. This technique involves subjecting the coil to tension forces, which helps to stretch and flatten out any waves or deformations. Tension leveling is typically done during the processing stage and is effective in correcting both edge waves and other surface defects. Moreover, roll leveling can be employed to correct edge waves in steel coils. This method utilizes a set of rolls to apply pressure to the coil, gradually flattening out any waves or deformations. Roll leveling is a versatile technique that can be used for various types of coil defects, including edge waves. Lastly, technology advancements have led to the development of automated edge wave correction systems. These systems utilize sensors and computer algorithms to detect and correct edge waves in real-time during the coil processing stage. This method ensures precise and consistent correction, minimizing the need for manual intervention and improving overall efficiency. Overall, the different methods of edge wave correction for steel coils include edge wave flattening, edge trimming, tension leveling, roll leveling, and automated correction systems. Each method has its own advantages and can be chosen based on the specific requirements and constraints of the coil processing operation.

- Q: What are the common coil defects and their causes?

- Some common coil defects include edge wave, center buckle, oil canning, and coil breaks. These defects can occur due to various causes such as improper tension during the coiling process, uneven cooling, material defects, or inadequate lubrication.

Send your message to us

Pre-painted Galvanized Steel Sheet Coil with Prime Quality and Best Price, Blue Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords