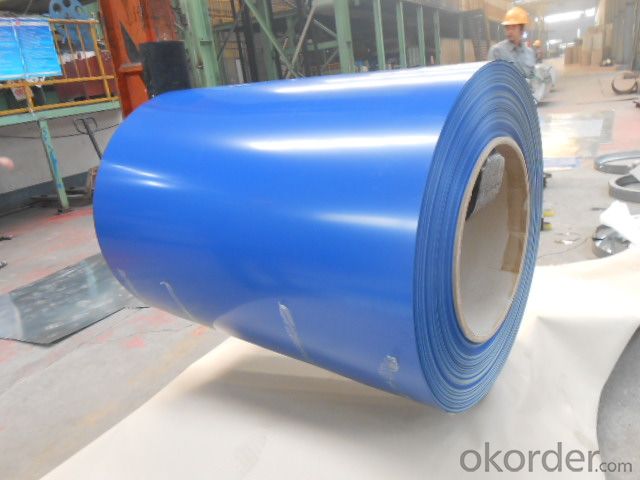

Pre-Painted Galvanized Steel Sheet/Coil in Prime Quality Blue Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: How do steel coils contribute to the renewable energy equipment industry?

- The renewable energy equipment industry relies heavily on steel coils, as they are a crucial component in the manufacturing process of various renewable energy technologies. Wind turbines, in particular, heavily rely on steel coils for their construction. The tower, nacelle, and rotor blades of wind turbines all require steel coils. When it comes to wind turbine towers, steel coils are used to fabricate the structural components that provide stability and support. These coils are rolled and welded together to form the tower, ensuring its strength and durability against the wind forces. Steel coils are also used in the production of the nacelle, which houses the generator and other essential components. Steel coils also play a significant role in the manufacturing of rotor blades for wind turbines. These blades are responsible for capturing wind energy and converting it into rotational energy. Steel coils are used to create the internal structure of the blades, providing the necessary strength to withstand the aerodynamic forces. These coils are often combined with composite materials to optimize the performance and efficiency of the blades. In addition to wind turbines, steel coils are utilized in other renewable energy technologies such as solar panels. In the manufacturing process of solar panels, steel coils are used to create frames and supporting structures that hold the photovoltaic cells in place. These frames ensure the stability and longevity of the solar panels, allowing them to effectively capture sunlight and convert it into electricity. To summarize, steel coils are an integral part of the renewable energy equipment industry. They provide the strength, durability, and structural support required by various renewable energy technologies. By enabling the production of wind turbines, solar panels, and other renewable energy equipment, steel coils contribute to the expansion and development of the renewable energy sector. This advancement is crucial in the global transition towards cleaner and more sustainable sources of energy.

- Q: I've heard on some 1911 forums that the slides of Armscor guns are now extruded. What is extruded steel? How is it made? Are they strong (4140carbon steel was used in the process).

- Extruded steel is only the steel being run through a die when it is heated, it usually reduces the size of the grain of the steel itself, enhancing toughness. Realistically though, in a handgun, it doesn't matter if the frame is cast or forged, both types will hold up to any amount of abuse, unless you use it as a sledgehammer, and are splitting stones with it, then the forged frame would win. 4140 is more than adequate for a slide/frame. Hell, even mild steel would be adequate as long as you don't mind some dings and scratches, and again, don't use it as a sledgehammer...

- Q: How many inches of steel can an AK47 using 7.62x39mm rounds penetrate through?

- It can't go through inches. It can go through up to 1/4 of an inch of plate steel but not much more. An M-16 can go through it as well and has less powder behind it but the 7.62X39 is a fat round and it takes a little more to get it through.

- Q: What are the challenges faced in the recycling of steel coils?

- One of the main challenges in recycling steel coils is the process of separating the different materials that may be attached to the coils, such as plastic or paper. These contaminants need to be removed before the steel can be recycled efficiently. Additionally, the size and weight of steel coils can pose logistical challenges in terms of transportation and storage. Lastly, ensuring that the recycled steel meets the required quality standards and specifications is another challenge faced in the recycling process.

- Q: What's the best material for color coated steel coil?

- The base material of color coated coil is mainly galvanized steel or galvanized alloy steel plate.

- Q: How are steel coils used in the production of HVAC systems?

- Steel coils are used in the production of HVAC systems as they serve as the primary component for heat transfer. These coils are responsible for absorbing heat from the surrounding air and transferring it to cool the interior of a building. Additionally, steel coils are used for the condenser coils in HVAC systems, where they aid in the removal of heat from the refrigerant, allowing for efficient cooling and dehumidification.

- Q: What are the dimensions of steel coils used in the structural component industry?

- The dimensions of steel coils used in the structural component industry can vary depending on the specific application and requirements. However, common dimensions for steel coils in this industry typically range from 0.5 to 3.0 millimeters in thickness and 600 to 2000 millimeters in width. The length of the coils can vary but is often around 2000 to 2500 meters.

- Q: How are steel coils used in the manufacturing of storage cabinets?

- Steel coils are used in the manufacturing of storage cabinets as they provide the raw material for forming the cabinet's metal components. Coils are unrolled, cut, and shaped into the necessary panels, shelves, and doors, which are then assembled to create the cabinets. The strength and durability of steel make it an ideal material for these cabinets, ensuring they can safely store and organize various items.

- Q: How does the surface finish of steel coils affect their performance?

- The surface finish of steel coils significantly affects their performance. A smooth and even surface finish enhances the coil's ability to resist corrosion, improves paint adhesion, and enhances the overall appearance of the final product. Additionally, a properly finished surface reduces friction, facilitating better processing and handling during manufacturing. Therefore, the surface finish of steel coils plays a crucial role in determining their durability, functionality, and aesthetic appeal.

- Q: How are steel coils inspected for camber?

- Steel coils are inspected for camber by using a straight edge or a camber gauge, which is placed on top of the coil to measure any deviation from straightness. The operator checks the distance between the straight edge and the coil at various points along its length to determine the amount of camber present.

Send your message to us

Pre-Painted Galvanized Steel Sheet/Coil in Prime Quality Blue Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords