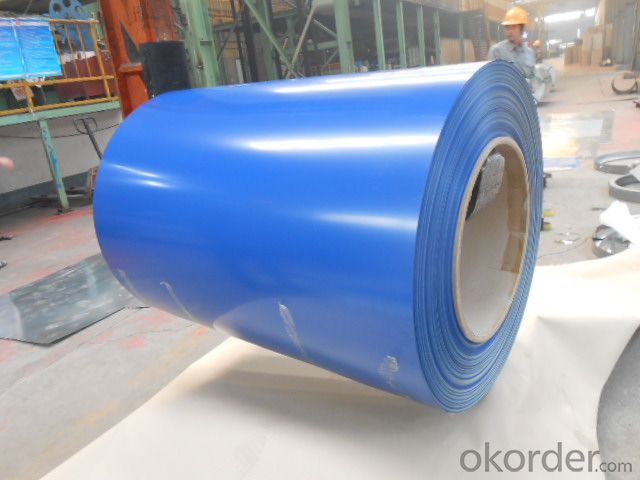

Pre-Painted Galvanized Steel Sheet,Coil with High Quality Blue Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: What are the common coil weights available for steel coils?

- The common coil weights available for steel coils vary depending on the specific application and industry requirements. However, there are a few standard coil weights that are commonly available in the market. These include: 1. Light coils: Light coils typically have a weight range of 3 to 6 metric tons (6,000 to 13,000 pounds). These coils are commonly used in industries such as automotive, construction, and appliance manufacturing, where smaller, more manageable coil sizes are preferred. 2. Medium coils: Medium coils generally range in weight from 6 to 15 metric tons (13,000 to 33,000 pounds). These coils are utilized in a wide range of industries, including construction, infrastructure, and general manufacturing. 3. Heavy coils: Heavy coils are typically heavier than 15 metric tons (33,000 pounds) and can go up to 30 metric tons (66,000 pounds) or more. These coils are commonly used in industries like shipbuilding, heavy machinery manufacturing, and infrastructure projects that require large and sturdy steel components. It's important to note that these weight ranges are not fixed and can vary depending on the specific requirements of the customer or industry. Additionally, some manufacturers may offer custom coil weights to suit unique project needs. It is always recommended to consult with a steel supplier or manufacturer to determine the most suitable coil weight for a specific application.

- Q: How are steel coils used in the production of metal furniture?

- Steel coils are used in the production of metal furniture as they serve as the primary raw material for manufacturing various components such as frames, legs, and supports. These coils are unwound and processed through cutting, bending, and shaping techniques to create the desired shapes and sizes. Additionally, steel coils provide the necessary strength and durability to ensure the longevity and stability of the final furniture products.

- Q: What are the dimensions of steel coils used in the construction materials industry?

- The dimensions of steel coils used in the construction materials industry can vary depending on specific requirements and applications. However, there are some common dimensions that are frequently used. Steel coils in this industry typically have a width ranging from 600mm to 2,000mm, with the most common widths being 1,000mm and 1,200mm. The thickness of these coils can range from 0.4mm to 2.5mm, with the most commonly used thicknesses being between 0.6mm and 1.2mm. The inner diameter of the coil, known as the core size, can vary from 508mm to 610mm, with 610mm being the most widely used core size. Additionally, the weight of these coils can also vary, with common weights ranging from 3 to 15 tons. It is important to note that these dimensions may vary based on specific project requirements and can be customized to suit the needs of a particular construction project.

- Q: How are steel coils used in the production of steel bolts?

- Steel coils are used in the production of steel bolts by being unwound and fed into a machine that cuts and shapes them into the desired bolt size and shape. The coils provide a continuous and uniform supply of steel, ensuring consistent quality and efficiency in bolt production.

- Q: I expect that I will be questioned about my knowledge in methoding for steel castings, in a interview. I dont know about it. Can someone explain me in simple language and give me some links, like how I can explain methoding for steel castings.....key points...help please...so that i will pass the interview as if I have experience in methoding....thanks

- It is very difficult to define Methoding of Steel castings by one sentence. Actually it encompasses the total casting process. Normally it would mean a) Pattern design i.e. what type of pattern it would be- wooden, metallic, split or full, loose or fitted on a match plate or any other, how will be the parting line. b) Design of the gating system. c) Design of risering i.e. numbers, size and location of risers. d) Design of molding process i.e. sand system to be used, mold box size. But to do justice to the above mentioned activities, you need to consider other parameters of the casting process such as chemical composition, solidification characteristics, pouring temperature, pouring time, knock out time etc. As I said Methoding of Steel castings means designing of the total casting process from inception to final product.

- Q: I want to buy a VERY sturdy bunkbed, but don't know which one would be better with not getting loose or falling apart.

- Metal/Steel. :)

- Q: How are steel coils used in the production of transportation equipment?

- Steel coils are used in the production of transportation equipment, such as automobiles, ships, and trains, to create various structural components. These coils are typically shaped and formed into parts like chassis, frames, bodies, and panels, providing strength, durability, and stability to the vehicles. Additionally, steel coils can be used in the manufacturing of wheels, axles, and suspension systems, ensuring reliable performance and safety in transportation equipment.

- Q: How are steel coils protected against UV radiation?

- Steel coils are protected against UV radiation through the application of protective coatings or paints. These coatings act as a barrier, shielding the steel from direct exposure to UV rays, preventing oxidation and degradation of the metal.

- Q: can u use stainless steel to make a coin? why or why not? answers based on facts plz.

- Stainless steel has been used by some countries to make coins, but it's not an ideal metal. When a coin is struck, a die comes down and strikes the blank with many tons of force (the blank is also sitting on top of another die--one has the image on the obverse (front) of the coin, while the other die has the image of the reverse of the coin). When the die strikes the blank, the force causes the metal in the blank to flow into the recesses of the die. The problem with stainless steel is that it doesn't want to flow into the die. To get an image, either the relief (how high the raised portion of the design will be) has to be very low, and the coin has to have a simple design, or they have to greatly increase the pressure of the strike. This slows the coining press down, and greatly shortens the life of the dies.

- Q: I wanted to know what is steel fabricating?

- Steel Fabricating/or Steel Fabricators is just a fancy way of saying that they sell steel products and a variety of related services. Thomas steel products has a wide range of steel products and services, from Windsor Republic Door Dist, Tie Wire, Steel Doors Frames, Snap Ties, S Parker Hardware Distributor, Reinforcing Steel Detail Drawings Avail, Rebar Fabrication, o_O.

Send your message to us

Pre-Painted Galvanized Steel Sheet,Coil with High Quality Blue Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords