PPGI Roofing Sheets/Color coated sheet coil ID508mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PPGI Roofing Sheets/Color coated sheet coil ID 508mm

1. Detailed Specifications:

| Product | PPGI Roofing Sheets/Color coated sheet coil ID 508mm |

| Base material | Hot dipped galvanized steel sheet |

| Top side: | 15-25µm |

| Back side | 5-8µm |

| Zinc coating : | 30-150g/m2 |

| Width | 700-1250mm |

| Thickness | 0.3-1.0mm , Thickness tolerance: +/- 0.02mm |

| Technique | Cold rolled—>hot dipped galvanized |

| Color | All RAL color,or be customized |

| Coil ID | 508m&610mm |

| Coil weight | ≤5 tons |

| Packing | standard seaworhty package |

| Special specifications can be negotiated. | |

2. Application of PPGI Roofing Sheets/Color coated sheet coil ID 508mm

They are mainly used in construction ,light industry, automobile, agriculture, animal husbandry, fishery and commerce,etc industries.

.Manufacture anticorrosion, industrial and roof boarding,roof grille.

.Make home appliance’s case, civil chimney, kitchen utensils.

.Corrosion resistant parts of cars.

.Food storage, meat and aquatic products’ freezing and processing equipment.

.The equipments to store and transport materials, and packing implements.

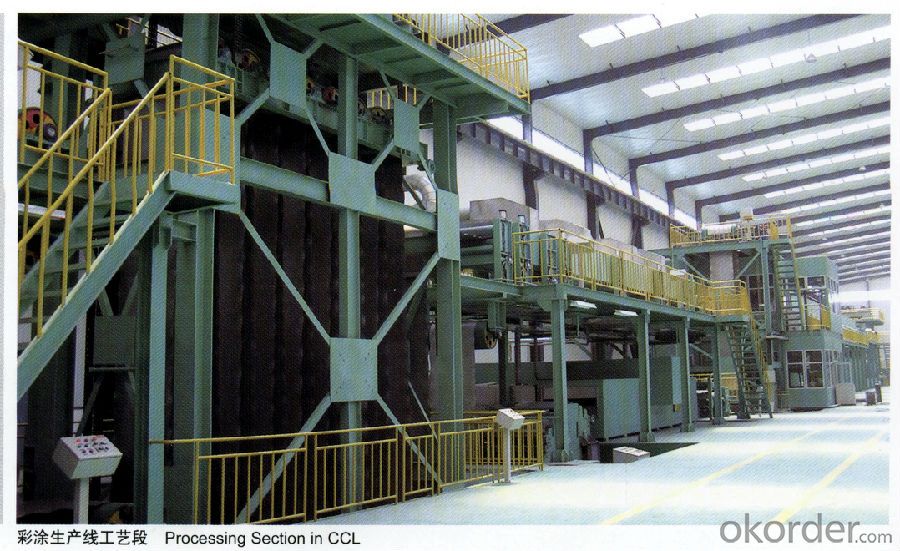

3. PPGI Roofing Sheets/Color coated sheet coil ID 508mm Image:

production Line:

production show:

4.Packaging & Delivery

(1)Metal Band Strapping (2) Outside Diameter Ring (3) Label

(4)Protective Steel Sheet (5) Water and Rustproof paper (6)Steel Sheet

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty:

1Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: How are steel coils used in the manufacturing of metalworking tools?

- The manufacturing of metalworking tools heavily relies on steel coils, which are an essential component in the process. These coils, typically made from high-quality steel, serve various purposes at different stages of production to produce a variety of metalworking tools. Blades and cutting tools, for instance, are one primary application of steel coils in metalworking tool manufacturing. These coils are usually cut into specific lengths and then shaped and sharpened to create blades used for cutting, shaping, and milling different metals. The use of high-quality steel in these coils guarantees durable, strong blades capable of withstanding the demanding conditions of metalworking processes. Another use of steel coils in metalworking tool manufacturing is for the production of drill bits and other types of tooling. The coils are shaped and machined to achieve the desired size and shape of the tool, followed by a hardening and tempering process to enhance their strength and durability. This ensures that the resulting tools can endure the high-speed drilling and cutting operations involved in metalworking. Additionally, steel coils are utilized to construct the bodies and handles of metalworking tools. The coils are typically formed into the desired shape and size using various techniques like bending, rolling, and stamping. These formed pieces are then welded or fastened together to create the final structure of the tool. The high-quality steel used in the coils ensures that the resulting tool bodies and handles possess strength, rigidity, and the ability to withstand the forces and vibrations associated with metalworking operations. In summary, steel coils are crucial in the manufacturing of metalworking tools as they are used to create blades, drill bits, bodies, and handles. These coils provide the necessary strength, durability, and precision required in metalworking processes. Considered an essential raw material, steel coils enable the production of high-quality, reliable, and efficient metalworking tools.

- Q: What temp does fire have to be to melt steel?

- You need about 2800 degrees to melt steel.

- Q: Aluminum and Steel brittle or ductile based on these results? and why? Steel Aluminium% Elongation 0.2510.2705Modulus of E in ksi11833.33964.71Tensile Strength (ksi)87.5 51.5Yield Strength (ksi)78.5 41

- Only steel(of this pair)might be liable to brittle fracture,which would be implied by almost zero elongation or reduction in area at fracture.On this basis the steel has not failed by brittle fracture.I would expect much more elongation in pure aluminium than your sample shows so I presume it to be brittle unless it is an alloy rather than commercially pure aluminium.However brittle fracture in metals is a particular phenomenon to be determined by impact tests and examination of fracture surfaces and is particularly relevant to metals with the body centred crystal structure.

- Q: How are steel coils priced and traded in the market?

- Steel coils are priced and traded in the market based on several factors. The primary factor is the current demand and supply dynamics of the steel industry. When the demand for steel coils is high, the prices tend to increase, and vice versa. Another important factor in pricing steel coils is the cost of raw materials, such as iron ore and coal, which are essential for steel production. Fluctuations in the prices of these materials can directly impact the pricing of steel coils. Additionally, the quality and specifications of the steel coils also play a significant role in determining their price. Higher-quality coils with specific characteristics, such as strength, corrosion resistance, or surface finish, may command a premium price in the market. The trading of steel coils is primarily done through various platforms, including physical exchanges, futures contracts, and over-the-counter (OTC) markets. Physical exchanges allow buyers and sellers to trade steel coils by exchanging physical deliveries. Futures contracts, on the other hand, enable traders to buy or sell steel coils at a predetermined price and future date, providing a way to hedge against price fluctuations. The OTC market is another avenue for trading steel coils, where buyers and sellers negotiate and agree on prices directly without going through a formal exchange. This provides flexibility and customization in trading, allowing for specific requirements to be met. Overall, the pricing and trading of steel coils in the market are influenced by demand and supply dynamics, raw material costs, quality specifications, and trading platforms. It is a complex process that requires careful consideration of various factors to determine fair prices and facilitate efficient trading.

- Q: My remington has a 28 inch barrel and was wondering if it would damage my shotgun to shoot steel out of it?

- If it says on the barrel that it will chamber 3 shells, then it is a MAGNUM barrel. The gun receiver should also have an M suffix at the end of its serial number.

- Q: What are the common uses of stainless steel coils?

- Stainless steel coils have various common uses in different industries. Some of the most common applications include manufacturing of kitchen appliances, automotive parts, construction materials, and medical equipment. Additionally, they are used in the production of pipes, tubes, and wire products, as well as in the food and beverage industry for processing and storage equipment.

- Q: How are steel coils used in the production of packaging materials?

- Steel coils are used in the production of packaging materials as they are processed and shaped into various forms, such as sheets or strips, which can be used to create durable and sturdy packaging products. These coils are often used to make packaging materials like cans, drums, and containers, providing strength, structural stability, and protection to the packaged goods during storage and transportation.

- Q: How are steel coils stored in warehouses?

- Steel coils are typically stored in warehouses by stacking them securely on top of each other, either directly on the warehouse floor or on specially designed racks. They are often stored vertically to save space and ensure stability. Additionally, to prevent damage and corrosion, steel coils are often wrapped in protective materials or placed on pallets.

- Q: What are the different methods of coil joining for steel coils?

- There exists a variety of techniques for joining steel coils, each with its own advantages and limitations. Some commonly employed methods encompass the following: 1. Welding: Among the most popular methods of coil joining, welding involves the use of heat to melt and fuse the edges of steel coils. Arc welding, resistance welding, or laser welding can be utilized for this purpose. Welding offers a robust and durable joint, although it can be time-consuming and necessitate skilled operators. 2. Mechanical fastening: This technique entails the use of mechanical fasteners like clips, staples, or bolts to connect the edges of steel coils. Mechanical fastening is relatively quick and straightforward, and it allows for easy disassembly if needed. However, the joint may not be as strong as welding and can be prone to loosening over time. 3. Adhesive bonding: Adhesive bonding involves the use of a suitable adhesive or glue to bond the edges of steel coils. This approach yields a strong and uniform joint, while also providing protection against corrosion. However, adhesive bonding may require surface preparation and curing time, and it might not be suitable for high-temperature applications. 4. Interlocking or tongue-and-groove joints: This method involves shaping the edges of steel coils in a manner that they interlock or fit together like puzzle pieces. Interlocking joints provide good alignment and are easily assembled and disassembled. Nevertheless, they may not yield as strong a joint as welding or mechanical fastening. 5. Coil-overlapping: In this method, the edges of steel coils are overlapped and clamped together using mechanical means. Coil-overlapping is a simple and cost-effective technique, albeit it may not yield a strong joint and can result in uneven coil edges. When selecting the appropriate method of coil joining for steel coils, it is crucial to consider factors such as application requirements, strength requirements, cost, and production efficiency.

- Q: How are steel coils used in the manufacturing of shipbuilding?

- Steel coils are used in shipbuilding as they are a primary source of high-quality steel that is necessary for constructing the various components of a ship, such as the hull, decks, and superstructure. These coils are processed and shaped into plates, beams, and other structural elements, which are then assembled to form the framework of a ship. The strength and durability of steel coils make them ideal for withstanding the harsh conditions at sea and ensuring the structural integrity of the vessel.

Send your message to us

PPGI Roofing Sheets/Color coated sheet coil ID508mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords