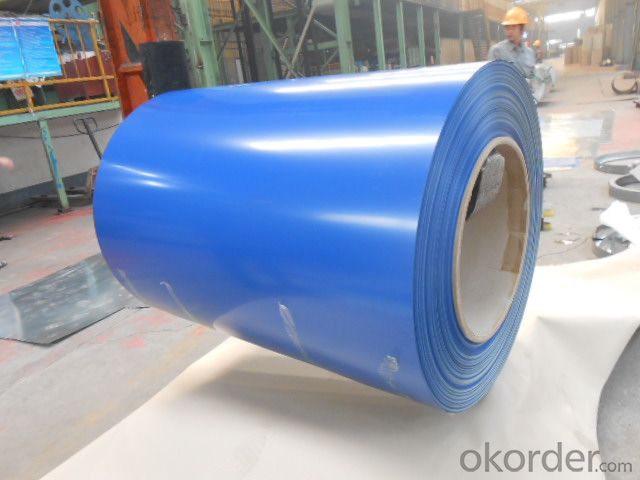

Pre-Painted Galvanized/Aluzinc Steel Coil (PPGI/PPGL) in Blue Color with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

4. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

5. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: Consider a steel rod of diameter 4.5 mm and length 3.3 m. If a compressive force of 4900 N is applied to each end, what is the change in the length of the rod?

- You need to calculate the stress on the rod and compare this with the mechanical properties of the steel. It would help if you were given more info. You will need to know something about the steel such as the yeild stress and E, the modulus of elasticity. The value of E is about the same for a wide range of steels. So long as the applied stress is below the yield stress, the strain is all elastic and is calculated from E. The real answer is that you can not answer this question since you do not know what the temperature is. Given the applied load, the change in length will be much different at room temperature than at 1500C.

- Q: What are the different methods of annealing steel coils?

- There are several different methods of annealing steel coils, each with its own advantages and applications. The main methods include full annealing, process annealing, and spheroidize annealing. Full annealing is the most common method and involves heating the steel coils to a temperature above its critical point, typically between 800 and 900 degrees Celsius (1472 and 1652 degrees Fahrenheit), and then slowly cooling it down in a controlled manner. This process helps to refine the grain structure of the steel, making it softer and more ductile. Full annealing is often used to relieve internal stresses, improve machinability, and enhance the overall mechanical properties of the steel. Process annealing, also known as subcritical annealing or stress relief annealing, is a method used to reduce the hardness and brittleness of steel coils. It involves heating the coils to a temperature below its critical point, typically between 550 and 650 degrees Celsius (1022 and 1202 degrees Fahrenheit), and then slowly cooling them down. This process helps to relieve internal stresses that may have developed during previous manufacturing processes, such as cold working or welding. Process annealing is commonly used to improve the formability and toughness of steel coils. Spheroidize annealing is a specific type of annealing that is used to soften high carbon and alloy steels. It involves heating the steel coils to a temperature slightly below its critical point, typically between 650 and 700 degrees Celsius (1202 and 1292 degrees Fahrenheit), and then holding it at that temperature for a prolonged period of time. This allows the carbides within the steel to transform into rounded or spheroidal shapes, which increases the steel's machinability and ductility. Spheroidize annealing is often employed in the production of cutting tools, bearings, and other applications where improved machinability is desired. In addition to these main methods, there are also variations and specialized techniques that can be used for specific purposes, such as recrystallization annealing, intercritical annealing, and solution annealing. Each method has its own set of parameters and temperature ranges, and the choice of annealing method depends on factors such as the type of steel, desired mechanical properties, and the intended application of the steel coils.

- Q: How are steel coils priced and traded in the market?

- Steel coils are priced and traded in the market based on several factors. The primary factor is the current demand and supply dynamics of the steel industry. When the demand for steel coils is high, the prices tend to increase, and vice versa. Another important factor in pricing steel coils is the cost of raw materials, such as iron ore and coal, which are essential for steel production. Fluctuations in the prices of these materials can directly impact the pricing of steel coils. Additionally, the quality and specifications of the steel coils also play a significant role in determining their price. Higher-quality coils with specific characteristics, such as strength, corrosion resistance, or surface finish, may command a premium price in the market. The trading of steel coils is primarily done through various platforms, including physical exchanges, futures contracts, and over-the-counter (OTC) markets. Physical exchanges allow buyers and sellers to trade steel coils by exchanging physical deliveries. Futures contracts, on the other hand, enable traders to buy or sell steel coils at a predetermined price and future date, providing a way to hedge against price fluctuations. The OTC market is another avenue for trading steel coils, where buyers and sellers negotiate and agree on prices directly without going through a formal exchange. This provides flexibility and customization in trading, allowing for specific requirements to be met. Overall, the pricing and trading of steel coils in the market are influenced by demand and supply dynamics, raw material costs, quality specifications, and trading platforms. It is a complex process that requires careful consideration of various factors to determine fair prices and facilitate efficient trading.

- Q: What are the common uses of stainless steel coils?

- Stainless steel coils are commonly used in various industries such as automotive, construction, manufacturing, and food processing. They are utilized for making a wide range of products including kitchen appliances, metal containers, piping systems, heat exchangers, and architectural components. The high corrosion resistance, durability, and aesthetic appeal of stainless steel make it an ideal material for these applications.

- Q: What are the challenges in storing and handling steel coils?

- Storing and handling steel coils pose several challenges due to their size, weight, and potential risks associated with their transportation and storage. Some of the challenges include: 1. Space requirements: Steel coils are generally large and bulky, requiring ample storage space. Finding suitable storage facilities that can accommodate the size and weight of the coils can be a challenge, especially in urban areas where space is limited. 2. Weight and handling: Steel coils can weigh several tons, making them difficult to handle safely. Specialized equipment such as cranes or forklifts with sufficient lifting capacity is necessary for moving and positioning the coils without causing damage or injury. 3. Stackability: Storing steel coils in a safe and efficient manner requires careful consideration of their stackability. Coils must be stacked in a way that prevents deformation or damage to the lower coils, ensuring stability and minimizing the risk of toppling. 4. Corrosion prevention: Steel coils are susceptible to corrosion, especially when exposed to moisture or harsh environmental conditions. Implementing proper corrosion prevention measures, such as protective coatings or climate-controlled storage, is crucial to maintain the quality and integrity of the coils. 5. Safety risks: Handling steel coils can be dangerous, as they can shift unexpectedly during transportation or storage. This poses a risk to workers involved in the handling process. Adequate training, appropriate personal protective equipment (PPE), and strict safety protocols are essential to minimize the potential for accidents or injuries. 6. Transportation challenges: Transporting steel coils from manufacturing facilities to storage facilities or end-users can be logistically complex. Coordinating the loading, securing, and unloading of the coils onto trucks or shipping containers requires careful planning and adherence to safety regulations. 7. Quality control: Steel coils must be stored and handled in a way that maintains their quality. Any mishandling or improper storage conditions can lead to deformations, scratches, or other defects that can affect the performance and value of the steel. Overall, the challenges in storing and handling steel coils require attention to detail, proper equipment, and adherence to safety protocols to ensure the integrity of the product, the safety of workers, and the efficiency of operations.

- Q: How are steel coils used in the production of telecommunications equipment?

- The production of telecommunications equipment commonly involves the use of steel coils, which offer structural support and durability. These coils are utilized to fabricate different components, including cabinets, racks, and enclosures. A significant application of steel coils in telecommunications equipment is seen in the manufacturing of cabinets. These cabinets serve as housing for the delicate electronic components and wiring utilized in telecommunications systems. Steel coils are typically shaped to form the cabinet structure, providing a robust and dependable enclosure for the equipment. The steel material also offers protection against external factors such as impacts, dust, and moisture, ensuring the longevity and integrity of the telecommunications equipment. Steel coils also find application in the production of racks for telecommunications equipment. These racks are designed to organize and provide accessibility to multiple devices, including servers, switches, and routers. The strength and rigidity of steel coils make them an ideal material for constructing these racks, ensuring they can bear the weight of multiple devices and withstand the constant handling and movement that occur in telecommunication environments. Moreover, steel coils are used to manufacture enclosures for telecommunications equipment. These enclosures act as protective casings, safeguarding sensitive electronic components from external influences such as electromagnetic interference and physical damage. Steel coils are often formed into specific shapes and sizes to create these enclosures, providing a sturdy barrier that shields the equipment from various external threats. In conclusion, steel coils play a crucial role in the production of telecommunications equipment by offering structural support, durability, and protection. They are employed in the creation of cabinets, racks, and enclosures, which ensure the proper functioning and longevity of the sensitive electronic components used in telecommunication systems.

- Q: Can steel coils be coated with anti-counterfeit materials?

- Yes, steel coils can be coated with anti-counterfeit materials. These materials can include specialized coatings, holograms, unique serial numbers, or other security features that help prevent counterfeiting and ensure the authenticity of the steel coils.

- Q: How are steel coils used in the manufacturing of chassis frames?

- Steel coils are used in the manufacturing of chassis frames by being shaped and welded to form the structural backbone of vehicles. These coils are typically cut and pressed into specific shapes to create the necessary strength and rigidity required for chassis frames.

- Q: How are steel coils inspected for surface defects using non-destructive testing methods?

- To ensure the quality and integrity of steel coils, non-destructive testing (NDT) methods are employed to inspect them for surface defects. Several common NDT methods are utilized in this process. Visual inspection is one of the most widely used methods, where trained inspectors visually examine the steel coils for visible defects like scratches, cracks, pits, or corrosion. Although this method is simple and cost-effective, it can only detect surface-level defects. Magnetic particle testing (MT) is another commonly used NDT method. It utilizes magnetism to identify surface and near-surface defects in ferromagnetic materials like steel. By applying a magnetic field and iron particles to the steel coil, any defects such as cracks or discontinuities become visible as the iron particles concentrate around them. Liquid penetrant testing (PT) is a different NDT method used for inspecting steel coils. It involves applying a liquid penetrant to the coil's surface, which is drawn into surface defects through capillary action. After removing excess penetrant and applying a developer, the defects become visible as the developer draws out the penetrant. Ultrasonic testing (UT) is widely used to detect both surface and subsurface defects in steel coils. It transmits high-frequency sound waves into the coil and analyzes the reflected waves to identify abnormalities. This method can detect defects like cracks, inclusions, and voids that may not be visible to the naked eye. Additionally, eddy current testing (ECT) is another NDT method for inspecting steel coils. It utilizes electromagnetic induction to detect surface and near-surface defects. By placing a coil carrying an alternating current near the surface of the coil being inspected, any changes in the coil's electrical conductivity caused by surface defects are detected and analyzed to identify and evaluate their severity. In summary, various non-destructive testing methods such as visual inspection, magnetic particle testing, liquid penetrant testing, ultrasonic testing, and eddy current testing are utilized to inspect steel coils for surface defects. These methods ensure the quality and integrity of the steel coils before they are used in various applications.

- Q: What are the common coil handling challenges?

- Common coil handling challenges include the risk of coil damage during handling and transportation, difficulties in aligning and positioning coils accurately, issues with coil slippage and instability, as well as the need for specialized equipment to safely and efficiently handle large and heavy coils. Additionally, managing coil edges and preventing injuries to workers are also common challenges faced in coil handling processes.

Send your message to us

Pre-Painted Galvanized/Aluzinc Steel Coil (PPGI/PPGL) in Blue Color with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords