PPGI Metal Building Materials /Pre-painted Hot Dipped Galvanized Steel Coil/Aluminized

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.PPGI Metal Building Materials Features:

. A strong anti-corrosion properties, good corrosion resistance. The use of hot dipped galvanized steel substrates for the Color Painted steel coil, with the exception of zinc have anti-corrosion layer, a layer of coatings have seized coverage and protection, allowing effective anti-rust products, galvanized coil about life than double.

. A good cold-formed molding processing, users can directly processed into finished products. Substituting wood to steel, easy to transport, and efficient construction, energy conservation.

2.Applications of PPGI Metal Building Materials

* Used as roof panel, wall panel in steel structure in warehouse,

factories exhibition hall container houses, cold storage

*It is also mainly used in light industry, automobile, construction,

animal husbandry, fishery and commerce, etc,

3.Product information:

| PRODUCT | PPGI Metal Building Materials |

| STANDARD | GB/T-12754: 2006, JIS330, ASTM A653, JIS G330, GB/T2518, ASTM A792, JIS G3321, JIS G3317 |

| BASE METAL | Hot dipped Galvanized steel sheet/coil, Hot dipped Galvalume steel sheet/coil |

| EQUIPMENT | Double coating double baking; three coating three painting |

| SUPPLY CAPACITY | 500,000 Tons per Year |

| SIZE | Thickness: 0.3mm-1.0 mm,thickness tolerance: +/- 0.02mm Width : 700mm—1250mm |

| ZINC COATING | 30g/m2-150g/m2 |

| PAINT THICKNESS | Top Side: 10-25 microns; Back Side: 4-8 microns |

| COIL WGT | Normally 5 Tons per Coil, aslo as required by customer |

| COIL ID | 508mm/610mm |

| SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

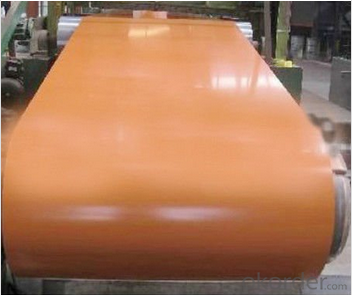

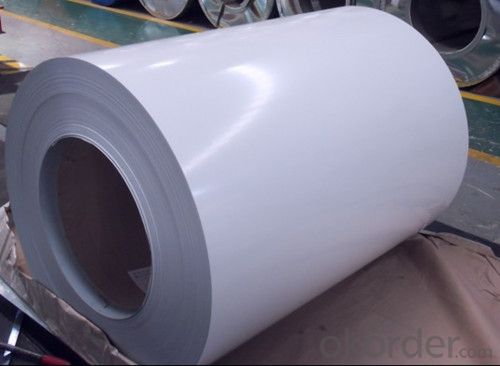

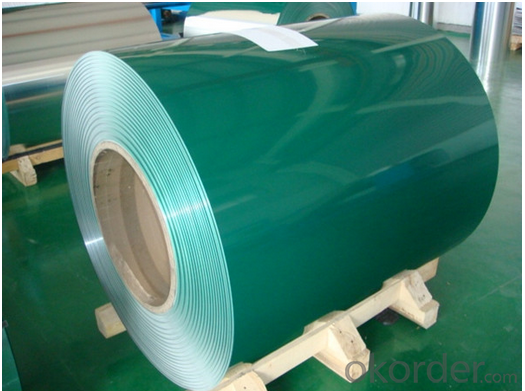

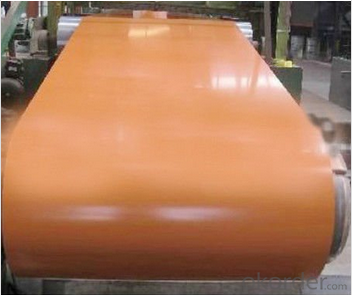

4.PPGI Metal Building Materials image:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: How can I judge the quality of steel?

- The quality of the alloy can be very well be judged by its appearance and lustrous surface. The more luster on the surface the more refine will the steel be. To judge its tenacity and endurance, the alloy can be subjected to a series of procedures involving stress and shock. There are many more scientific methods of measuring the quality of the alloy such as texture measurement technique etc are also employed. In layman’s term the quality can be measured by the hardness of surface, brightness and smoothness of the surface and absence of any depressions or troughs.

- Q: What are the factors driving the growth of the steel coil industry?

- There are several factors driving the growth of the steel coil industry. Firstly, the increasing demand for steel products across various sectors such as construction, automotive, and infrastructure is contributing to the growth of the industry. Steel coils are widely used in these sectors for manufacturing various products such as automobiles, buildings, bridges, and pipelines. Secondly, rapid industrialization and urbanization in emerging economies are fueling the growth of the steel coil industry. Countries like China, India, and Brazil are witnessing significant infrastructure development and construction activities, which require a large amount of steel coils for various applications. Additionally, technological advancements in the manufacturing process and the use of advanced steel alloys are driving the growth of the industry. These advancements have led to the production of high-quality steel coils that offer better strength, durability, and corrosion resistance. Moreover, the growing focus on sustainable and eco-friendly practices is also driving the growth of the steel coil industry. Steel is a highly recyclable material, and the increasing awareness about the environmental benefits of using steel is boosting its demand. Furthermore, favorable government policies and initiatives to promote domestic steel production and reduce imports are also contributing to the growth of the industry. Governments are implementing measures such as import tariffs and subsidies to support local steel manufacturers, which is driving the demand for steel coils. In conclusion, the factors driving the growth of the steel coil industry include increasing demand from various sectors, rapid industrialization, technological advancements, environmental awareness, and supportive government policies.

- Q: What are the different methods of embossing steel coils?

- There are several methods of embossing steel coils, including roller embossing, heat embossing, and laser embossing. Roller embossing involves using engraved rollers to press a pattern onto the steel surface. Heat embossing uses heat and pressure to create raised designs on the steel coils. Laser embossing utilizes laser technology to etch intricate patterns onto the steel surface. These methods allow for the creation of unique textures and designs on steel coils for various applications.

- Q: Why are properties of steel not identical?

- Grade 440C is one of the highest strength stainless steels. It is also very wear resistant. Good for use as ball bearings and other high wear applications. 400C has the highest carbon content of the 440 steels. 440A and 440B are identical but have lower carbon contents and have lower strengths and higher corrosion.

- Q: What are the different types of steel coil packaging materials?

- Some common types of steel coil packaging materials include wooden crates, steel frames, plastic strapping, stretch wrap, and steel bands.

- Q: What are the different methods of levelling steel coils?

- Different methods are employed to level steel coils, depending on their specific requirements and applications. Some commonly used methods include: 1. Roller Leveling: This method utilizes a series of rollers to apply pressure on the steel coil, effectively reducing residual stresses and eliminating any waviness or curvature. It is commonly used for achieving high flatness in thinner gauge coils. 2. Stretch Leveling: In this method, the steel coil is stretched beyond its yield point to eliminate shape defects. The coil is subjected to tension in a stretcher leveler machine, which elongates the material and removes inherent stresses. It is often used for achieving greater flatness in thicker gauge coils. 3. Temper Milling: This method involves passing the steel coil through a temper mill equipped with work rolls on top and bottom. The temper mill applies tension to the coil, flattening it and improving its shape and surface quality. It is typically used for higher strength steel grades. 4. Corrective Leveling: When the steel coil exhibits significant shape defects like wavy edges or center buckles, corrective leveling is employed. This method selectively removes material from specific areas of the coil to achieve a flat and uniform surface. Laser or plasma cutting machines are often used for this process. 5. Tension Leveling: Similar to stretch leveling, tension leveling applies tension to the coil without exceeding its yield point. Bridle rolls are used to stretch the material, eliminating internal stresses and leveling the coil. It is commonly used for achieving flatness in higher strength and thinner gauge coils. These methods can be used individually or in combination, depending on the specific requirements and desired end product. Each method has its advantages and limitations, and the choice of leveling method depends on factors such as coil thickness, material properties, and desired flatness.

- Q: How are steel coils used in the production of automotive structures?

- Various methods involve the usage of steel coils in the production of automotive structures. To begin with, these coils serve as the primary material for manufacturing car bodies and frames. Typically composed of high-strength steel, known for its durability and crashworthiness, these coils undergo processing and forming to create different automotive components such as panels, doors, roofs, and pillars. Moreover, steel coils are also utilized in the creation of various structural components within an automobile. For instance, they contribute to the fabrication of suspension systems, chassis, and other vital parts that provide stability, strength, and support to the vehicle. Steel coils frequently find application in the production of structural beams, reinforcement bars, and other load-bearing elements that ensure the overall strength and safety of the vehicle. Furthermore, steel coils play a significant role in the manufacturing of automotive parts that require precise shaping and forming processes. These coils are fed into stamping presses, where they undergo a series of operations including cutting, bending, and shaping to produce intricate parts such as brackets. The versatility of steel enables the production of complex automotive structures with exceptional accuracy and precision. Additionally, steel coils are crucial in the production of automotive exhaust systems. Typically composed of stainless steel, which exhibits excellent resistance to corrosion and high temperatures, these coils are formed and welded into exhaust pipes, mufflers, and catalytic converters, guaranteeing the durability and longevity of these critical components. In conclusion, the utilization of steel coils is essential in the production of automotive structures. They are employed in the creation of car bodies, frames, suspension systems, chassis, and other structural components. Steel coils also play a vital role in the manufacturing of precise and intricate automotive parts, as well as exhaust systems. Overall, the presence of steel coils contributes significantly to the strength, safety, and longevity of automotive structures.

- Q: They both sell the same thingIf prices are to high companies won't by the steelIf prices are to low then the steel company won't earn enoughWhy are some steel companies more successful than others

- Steel is a global commodity. There is some variety in product (flat rolled, tubing, etc), but basically the same product worldwide. Cost to the customer includes shipping of a very heavy product. Inputs are also heavy and costly to ship. Inputs: - Coal - Iron Ore. Some firms have the ability to recycle old steel, a competitive advantage. - Energy (very energy intensive industry) - Labor - Machinery. A new blast furnace is more efficient than 50 years old. So the most profitable steel firms have some of these characteristics: - Proximity to raw materials - Proximity to customers - Access to cheaper means of transportation; rail and sea - Newer machinery - Cheaper labor force - Reasonable cost for electricity and fuel for furnaces

- Q: Will a 8mm steel ball fired from a 150lbs crossbow kill small game and if so, from how many yards?

- People usually compare regular fiber stringed crossbows with the string in steel ball crossbows. steel ball crossbows shoot with steel cables that can take the light weight of the ball . On top of that they are ALLWAYS have cams that reduce the tension when releasing the ball. I own a 160 lbs crossbow that shoots both bolts and 8mm balls and I love it, it can take a raccoon , a rabbit , even a turkey and it is very easy to reload since it keeps several balls in the magazine. About how accurate it is , as most shooting weapons it is a matter of practice. I have a pistol 6 mm balls and is really fun, I don't think you can kill much with that one but it is fun to shoot at around the house. I would give it a try , you might be pleasantly surprised.

- Q: Steel is strong in both tension and compression. Concrete is only strong in compression, and is very fragile in tension. Plus, concrete is heavy--a huge drawback in, say, a bridge deck. And its fairly expensive. And it hides the condition of the steel embedded within it. So what does it bring to the table? Why use it at all?

- Pre stressed concrete is held in compression by the steel cables within.

Send your message to us

PPGI Metal Building Materials /Pre-painted Hot Dipped Galvanized Steel Coil/Aluminized

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords