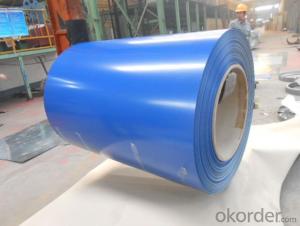

PPGI Color Coated Galvanized Steel Coil Blue Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Pre-Painted Galvanized/Aluzinc Steel Coil Description:

With GI as base material, after pretreatment (degrease and chemical treatment ) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized (aluzinc) steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

2.Main Features of the Pre-Painted Galvanized/Aluzinc Steel Coil:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Pre-Painted Galvanized/Aluzinc Steel Coil Images

4.Pre-Painted Galvanized/Aluzinc Steel Coil Specification

Standard: AISI, ASTM, BS, DIN, GB, JIS

Grade: DX51D, DX52D

Thickness: 0.17-2.0mm

Brand Name: KMRLON

Model Number: coil

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: Coated

Application: Boiler Plate

Special Use: High-strength Steel Plate

Width: 20-1250mm

Length: customized

commoidty: pre-painted galvanized steel coil

Thickness: 0.13-4.0mm

width: 20-1250mm

zinc coating: 40-180g/m2

printing thickness: top side: 20+/-5 microns, back side: 5-7 microns

color: all RAL color

surface treatment: color coated

coil weight: 4-7 tons

coil ID: 508/610mm

packaging: standard seaworthy packing

5.FAQ of Pre-Painted Galvanized/Aluzinc Steel Coil

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

4. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

5. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: The highest quality i have seen is 9260 and i want to know if there is a higher quality steel.

- Types of steel are one issue. But the quality of steel no matter what type is even more important. The only way to be sure that you are getting a good blade is to buy from someone that already has a reputation for producing great blades. Stop the questions about who thinks what type of steel is best and investigate the steel blades offered by companies like Bugei Trading company. they have good blades. Opinions vary, but Bugei has proven that they make good swords. That is all that is needed to be known. Any questions you have are best directed to them, not here.

- Q: There's this huge community of steelians (steelites?) in my town. Has anybody heard of this Dr. Steel?

- steel okorder thank you for posing this question. all hail dr.steel.

- Q: How are steel coils used in the manufacturing of construction formwork?

- Steel coils are used in the manufacturing of construction formwork to create the framework and support structures needed for pouring concrete. The steel coils are typically shaped and cut into various sections to form the desired shape and size of the formwork. These coils provide strength, durability, and stability, ensuring that the formwork can withstand the weight and pressure of the concrete during the construction process.

- Q: You have two steel wool pads,one is cut up into little pieces, and the other is whole, and they are both submerged in water. 1.Which steel wool pad will rust quicker?2.How much faster will that pad rust? (estimate+explain the estimate)6.How could you make the steel wool pad rust faster?Please dont tell me to do my homework because I tried, but I bought the wrong type of steel wool

- steel wool = iron fibers and rusts easily in air iron + Oxygen BUT the blue soap protects the iron at first. that needs to be cleaned off. damp surfaces speed the rusting but compeletly underwater there is not much O2, ther eis some temperature has an effect. the rusting depends ofn the area of the fibers which does NOT change when you cut th epad in smaller pieces. a good beginners experiment In old times thye thought the rusted material would lose weight becasuse it was not solid iron any more careful experiments showed it gained weight and lead to and understanding of chemistry

- Q: I'm a Hobbyist and want to Build my own axial-flow jet engine,can I use steel as the Turbine blades instead of Titanium which I can't get easily?? What about the other parts I can use for...?!

- You could but you will have to run lower pressures and speed and thus lower power output. You should do some research the Me 262 the Nazi's built. I don;t know but I think they used steel. That's why the engine had to be serviced every few hours of flight.

- Q: What are the different types of steel finishes available for coils?

- There are several types of steel finishes available for coils, including hot rolled, cold rolled, galvanized, and coated finishes.

- Q: What materials are used to make steel coils?

- Steel coils consist primarily of steel, an alloy primarily composed of iron and carbon. The choice of steel type for coil production depends on the desired properties and applications. Carbon steel is typically the preferred option due to its strength, durability, and versatility. Additional alloying elements, like manganese, silicon, nickel, or chromium, may be incorporated to enhance specific steel characteristics or properties. To produce steel coils, the raw materials are melted, the molten steel is refined, and specialized equipment and processes are employed to shape it into coils.

- Q: What are the different types of steel coil slitting processes?

- There are several different types of steel coil slitting processes, each with its own benefits and considerations. Here are some of the most common types: 1. Rotary slitting: This is the most traditional and widely used slitting process. It involves a rotating circular blade that cuts through the coil. Rotary slitting is highly precise and can produce narrow strips, making it suitable for a wide range of applications. 2. Loop slitting: In this process, the coil is fed through a loop before being cut. Loop slitting allows for high-speed processing and can handle thicker materials. It is commonly used for heavy-duty applications and large coils. 3. Drag slitting: Also known as shear slitting, this process uses a stationary blade that pulls the material through to make the cut. Drag slitting is suitable for thinner materials and offers a high-quality edge finish. 4. Crush slitting: This process involves pressing the material between two rollers to make the cut. Crush slitting is commonly used for delicate materials that require a gentle cutting action. It can produce clean cuts and minimize burrs. 5. Laser slitting: As the name suggests, this process uses a laser beam to cut through the coil. Laser slitting offers high precision and can handle a wide range of materials. It is particularly useful for specialty steels and thin strips. Each type of steel coil slitting process has its own advantages and limitations, so it's important to consider factors such as material thickness, coil size, and required strip width when choosing the appropriate method. Additionally, factors like cost, speed, and edge finish should also be taken into account to determine the best process for a specific application.

- Q: What are the different grades of steel used in coils?

- There are several different grades of steel that are commonly used in coils, including low carbon steel, high carbon steel, stainless steel, and advanced high-strength steels. Each grade has its own unique properties and is chosen based on the specific requirements of the application, such as strength, corrosion resistance, and formability.

- Q: My teacher says if they were that they would still be standing today. I'm not sure if he means the reinforced steel in the concrete beams, columns etc or if the whole beams and columns floor etc were were made of reinforced steel.

- Reinforced Steel is found in concrete, and if the towers were built with reinforced concrete (concrete beams with rebar) then they would likely still be standing. The twin towers were made of steel. When steel is heated up, it deforms and collapses, which is why it didnt stand up. One of the top 2 things against steel is that it is not fire resistant.

Send your message to us

PPGI Color Coated Galvanized Steel Coil Blue Color

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords